Structure for putting bricks into annealing electric stove hearth

A technology of laying bricks and electric furnaces, which is applied in the field of industrial heat treatment equipment, can solve the problems of easy falling off of electric furnace wires, unreasonable structure, and many seams of laying bricks, so as to improve the overall heat preservation effect, reduce power consumption, and reduce seams Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

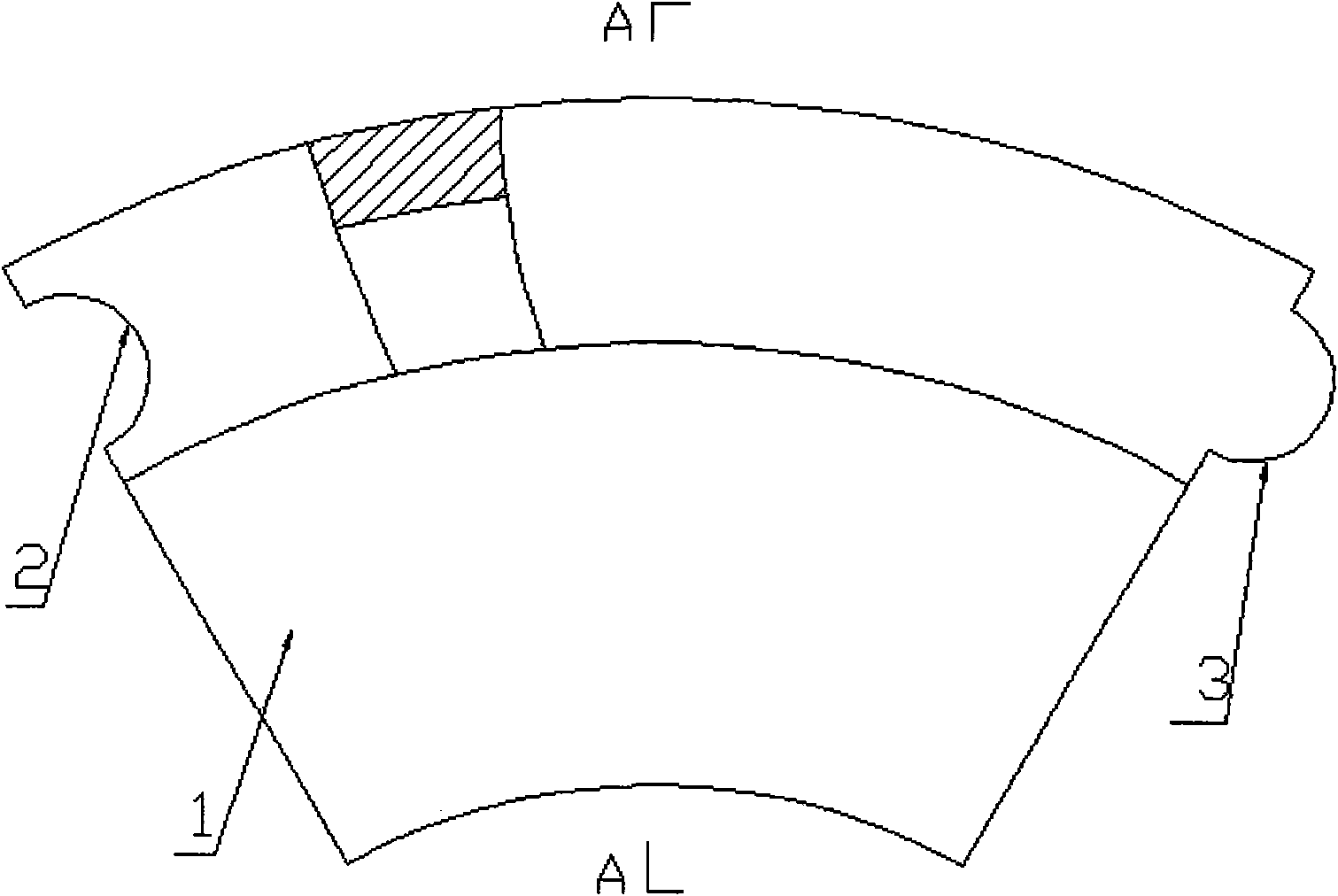

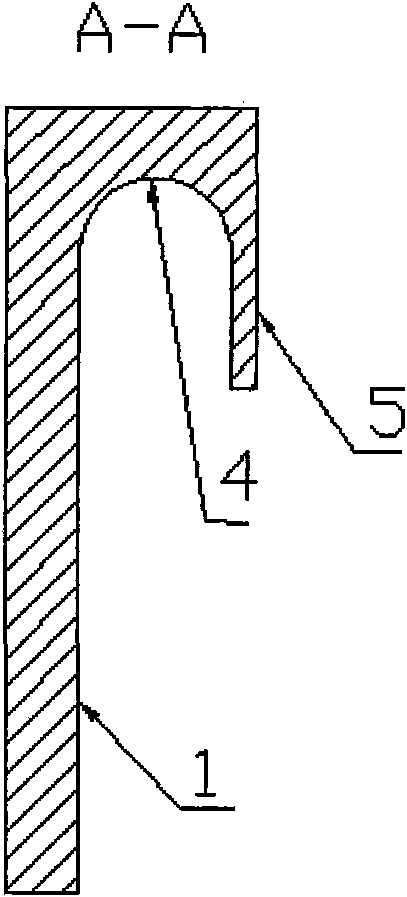

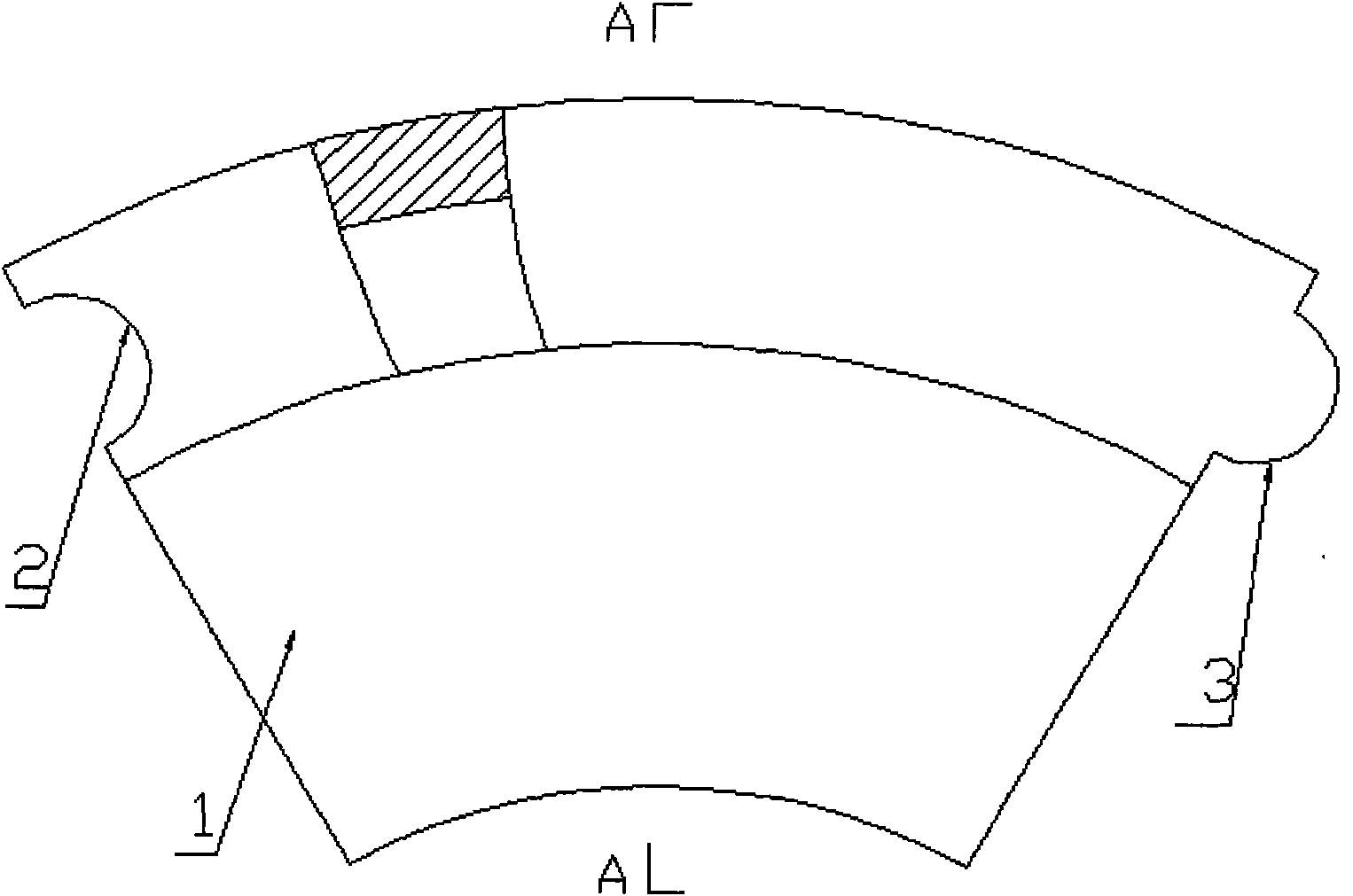

[0010] The fan-shaped angle of the brick body (1) is made into an included angle of 60°, and the convex arc groove (3) and the concave arc groove (2) are respectively made on the raised parts of the fan-shaped two sides. The slots on the top fit snugly. In the outer circle direction of putting brick (1), make flange (5) along outer circle direction, in the inboard of flange (5), make inward semicircle groove (4), this is as installing and fixing electric stove wire place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com