Phase change insulating brick and manufacturing method thereof

A manufacturing method and technology of heat-insulating bricks, which are applied in the field of building bricks, can solve problems such as poor thermal insulation performance of partition boards or bricks, failure to meet energy-saving requirements, etc., and achieve improved indoor temperature environment, good energy-saving effects, The effect of increasing the tensile and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

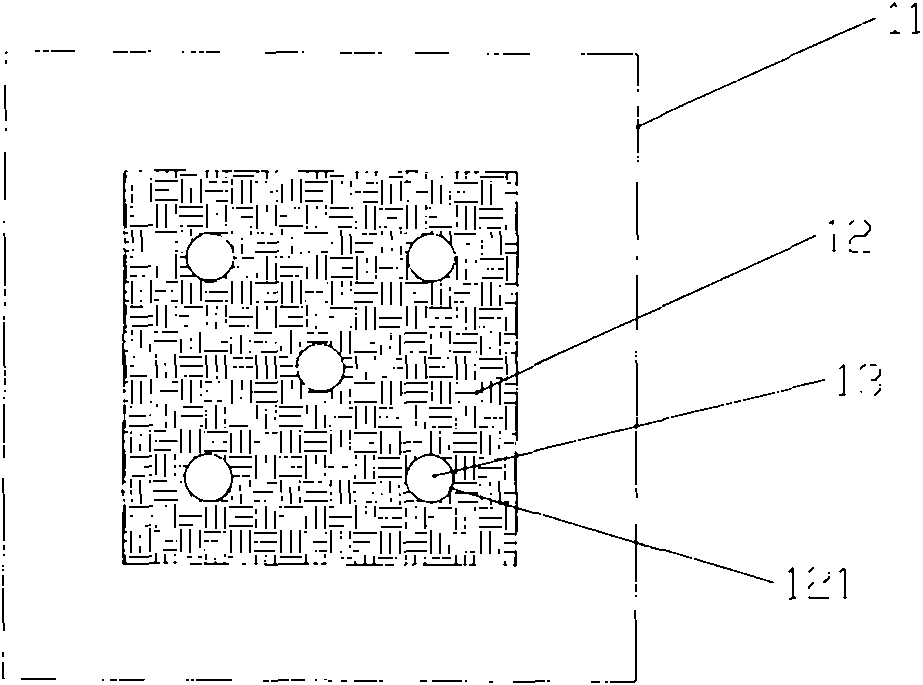

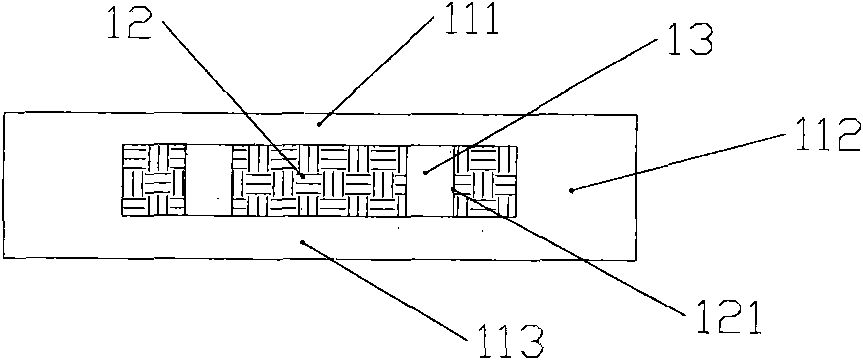

[0034] Such as Figures 1 to 3 As shown, a phase change heat insulating brick 1 according to the present invention includes a central phase change material core layer 12 and a brick peripheral hard material structure protective layer 11 covering the middle phase change material core layer 12; The outer hard material structure protective layer 11 of the brick body is an integrally formed rectangular structural layer, which includes an upper protective layer 111, a lower protective layer 113 and a peripheral protective layer 112; between the upper protective layer 111 and the lower protective layer 113 There is a connecting post 13 passing through the middle phase change material core layer 12 and integrally formed with the upper sheath layer 111 and the lower sheath layer 113 .

[0035] Further, the central phase change material core layer 12 is provided with five holes 121 penetrating up and down, and five connecting columns 13 passing through the holes 121 are arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com