Drill rod joint positioning and controlling method of continuous cycle drilling system

A drill pipe joint and positioning control technology, applied in drill pipe, drilling equipment, drill pipe, etc., to improve safety and reliability, reduce hidden troubles, and avoid rubber wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Taking a drill pipe joint positioning control method of a continuous circulation drilling system as an example, the present invention will be further described in detail.

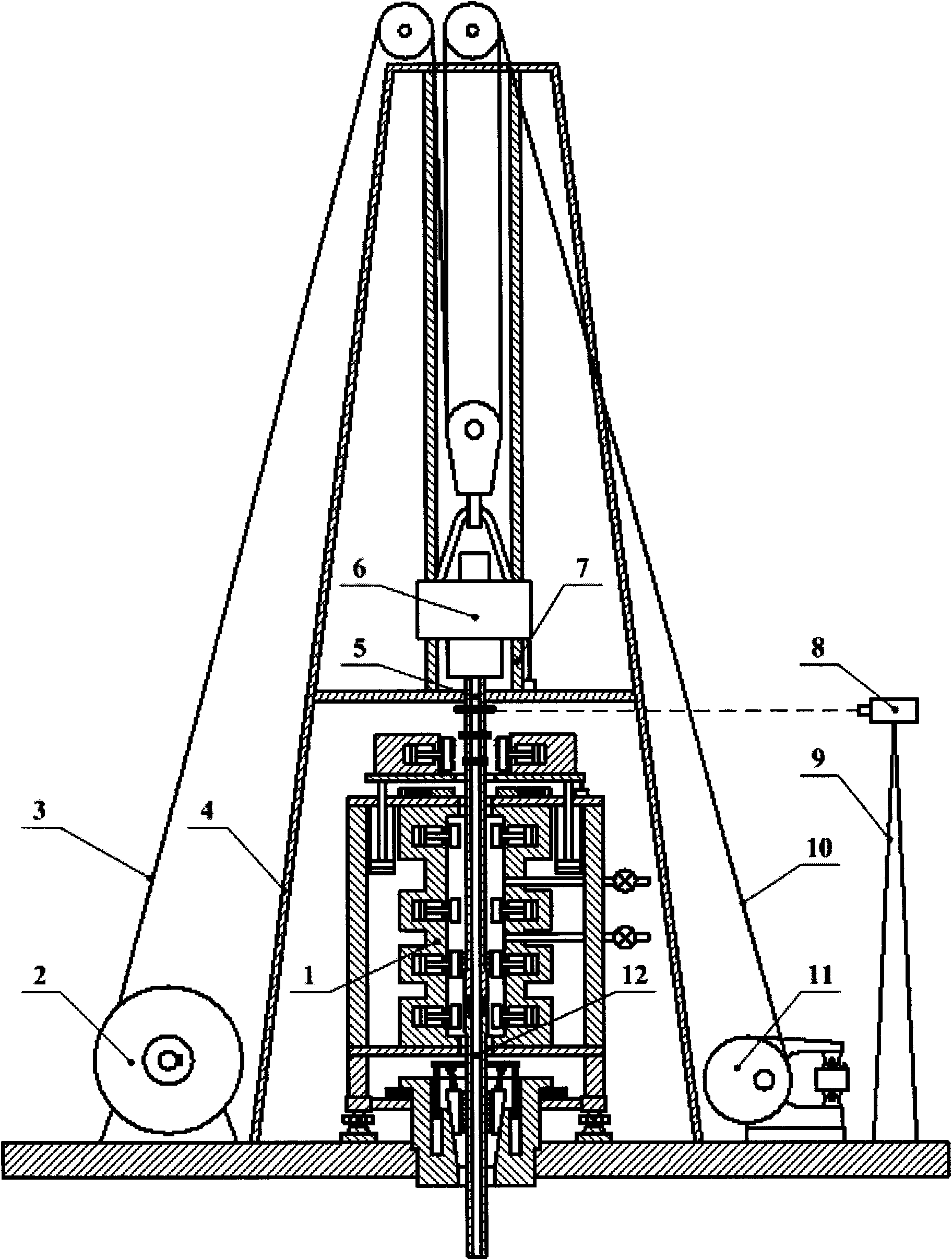

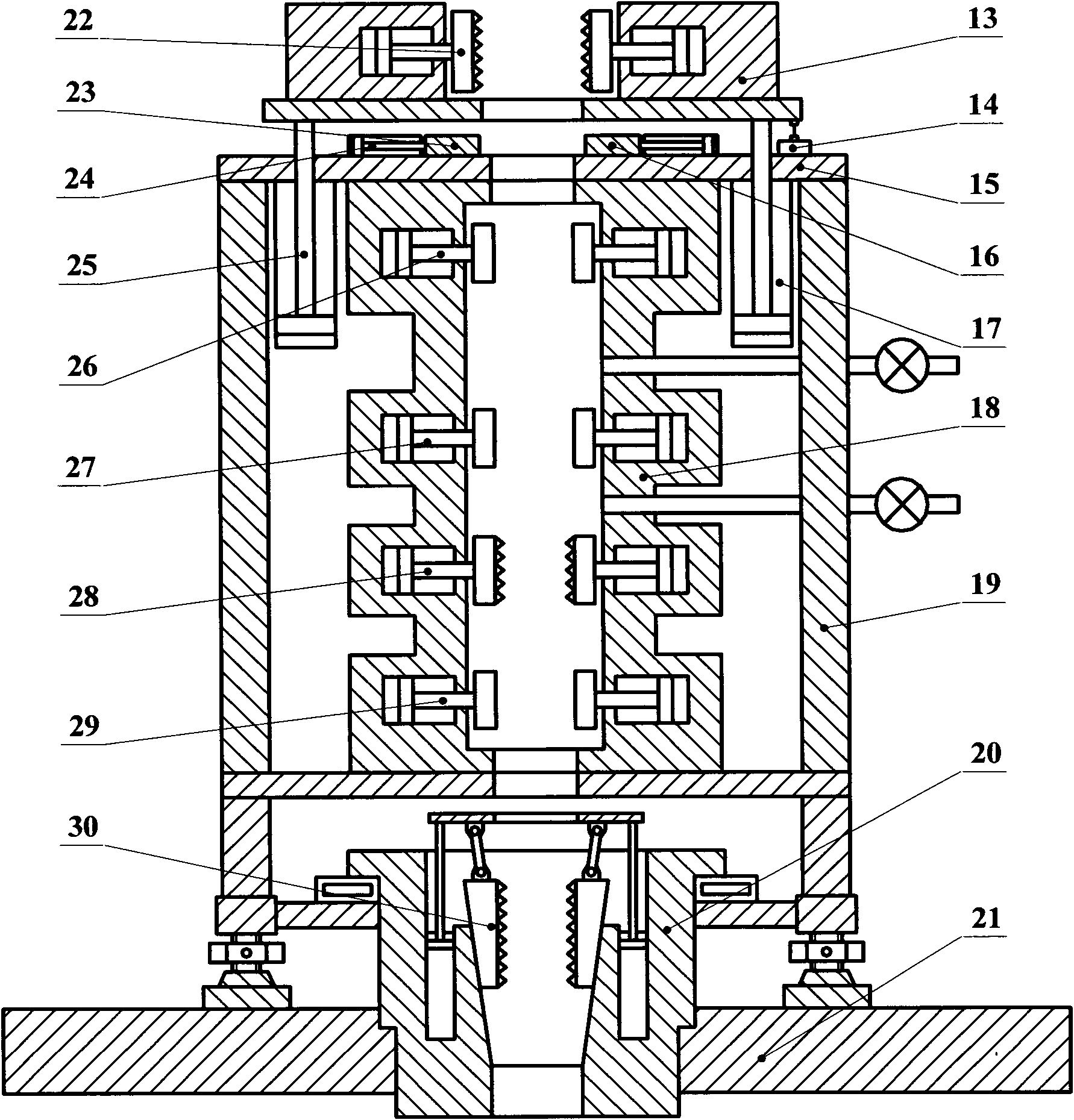

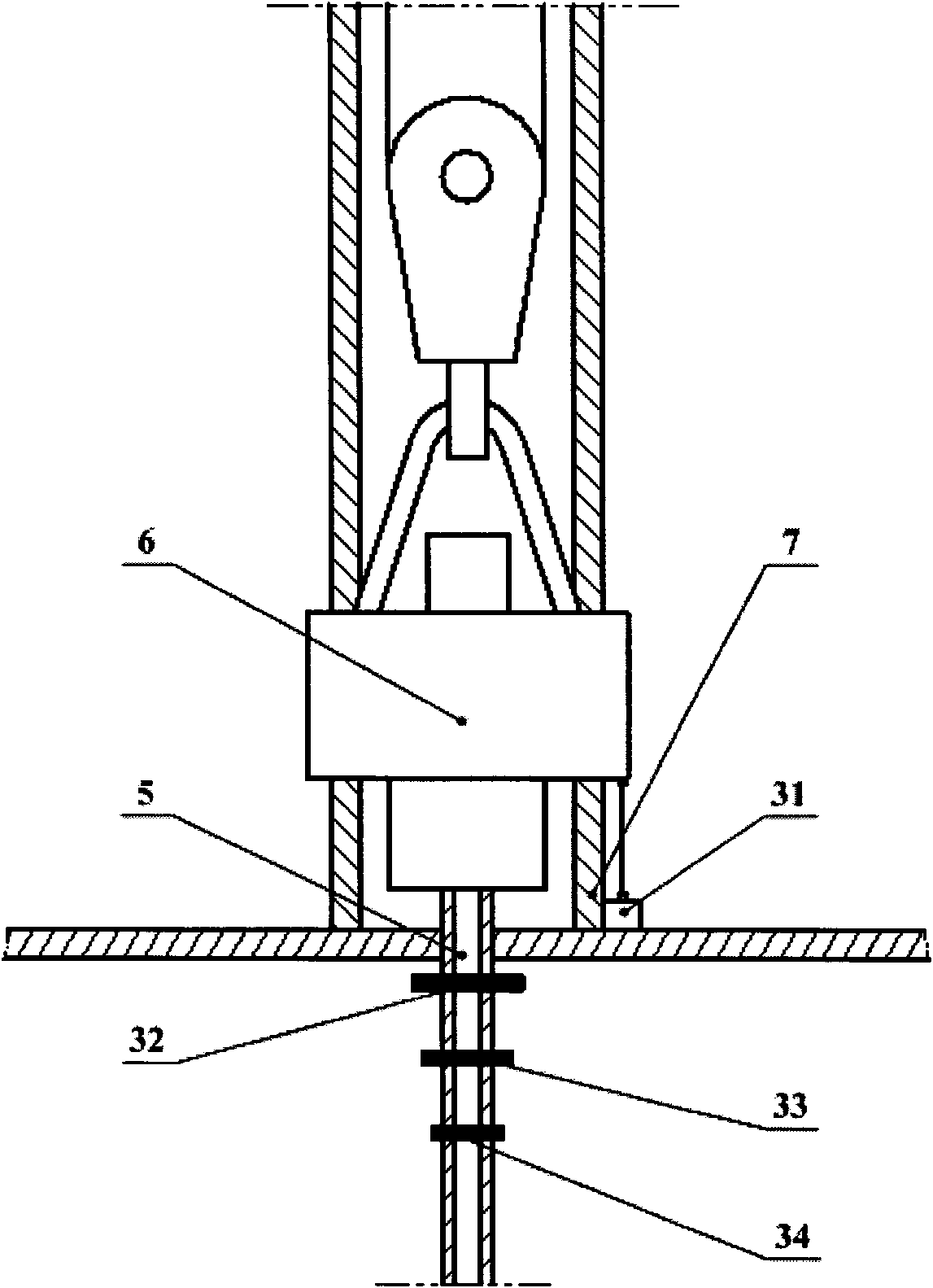

[0028] refer to figure 1 with figure 2 . The equipment adopted is: a host 1 is fixed on the base 21, and the host 1 is opposite to the wellhead. The main engine 1 is composed of a drill pipe power tong 13, a balance compensation device 17, a cavity assembly 18, a support assembly 19, and drilling power slips 20; the balance compensation device 17 is composed of four balance compensation oil cylinders 25, and the balance compensation The oil cylinder 25 is fixed on the upper connecting plate 15 of the bracket assembly 19; the drill pipe power tongs 13 are fixedly connected with the piston rod of the balance compensation cylinder 25; the cavity assembly 18 is fixed on the bracket assembly 19, and the upper half-sealed gate 26. The full-sealed ram 27, the back clamp 28 and the lower ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com