Integrated fan propeller and manufacturing method thereof

A fan impeller and manufacturing method technology, applied in the field of fan impellers, can solve the problems of restricting the rational utilization of production capacity resources, the inability to use assembly line production, and complicated manufacturing processes, etc., and achieve considerable material utilization, improve material utilization, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

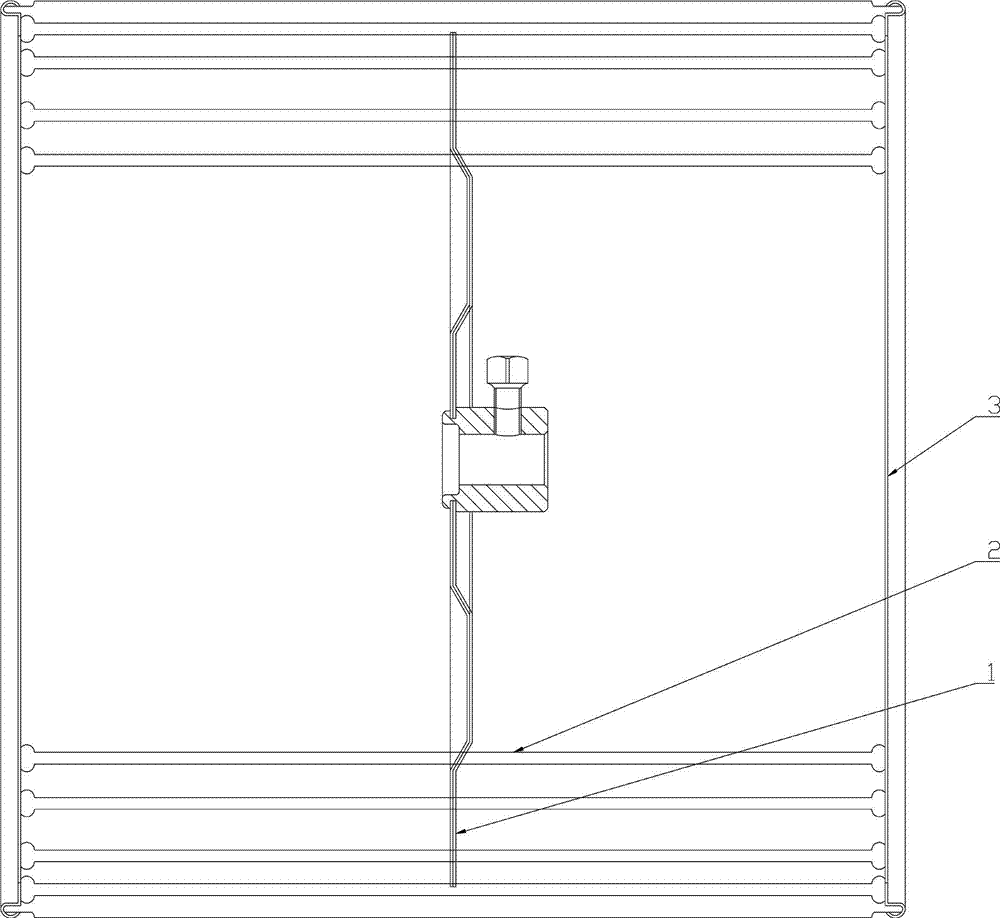

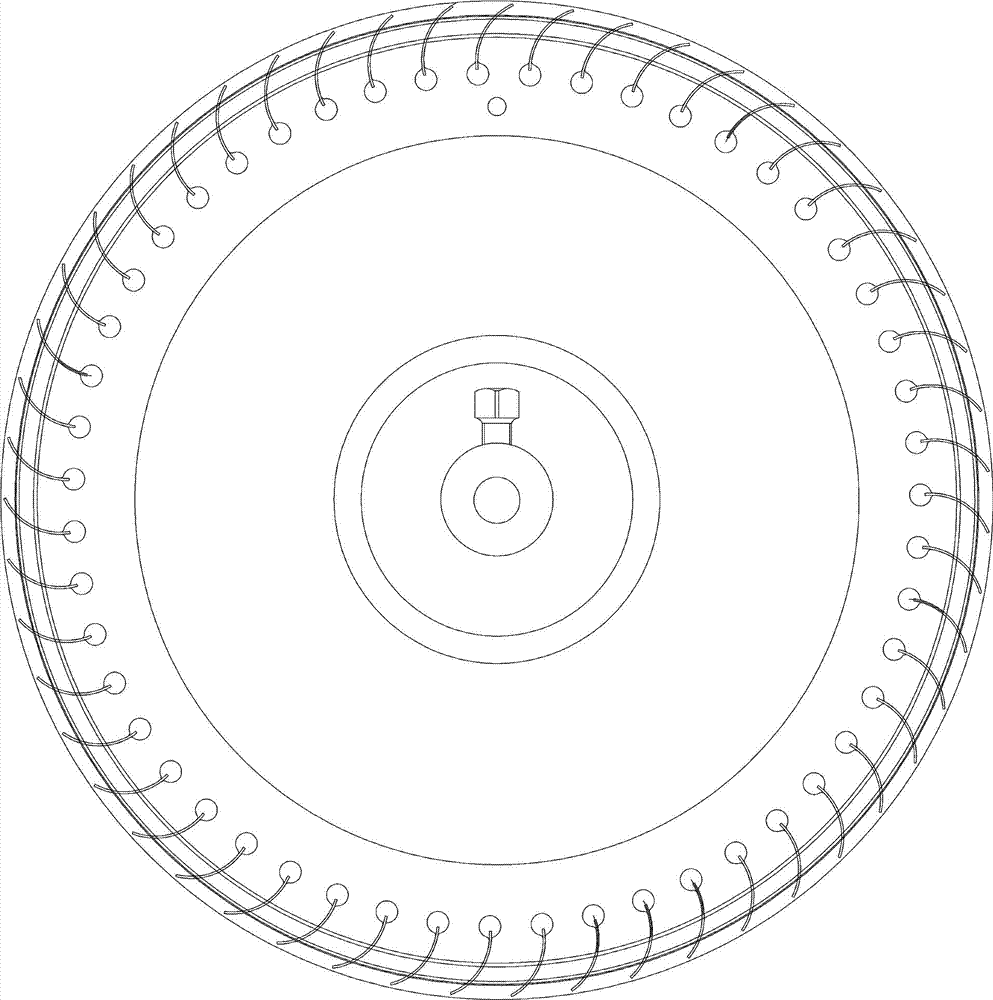

[0037] Such as figure 1 , figure 2 As shown, the integrated fan impeller of the present invention includes a blade cylinder 2, two end rings 3, and a middle plate 1, and the two ends of the blade cylinder 2 are respectively fixedly connected to the end rings 3; The blade cylinder 2 is fixedly connected with the middle plate 1;

[0038] The centerlines of the two end rings 3 and the middle disc 1 are on the same axis.

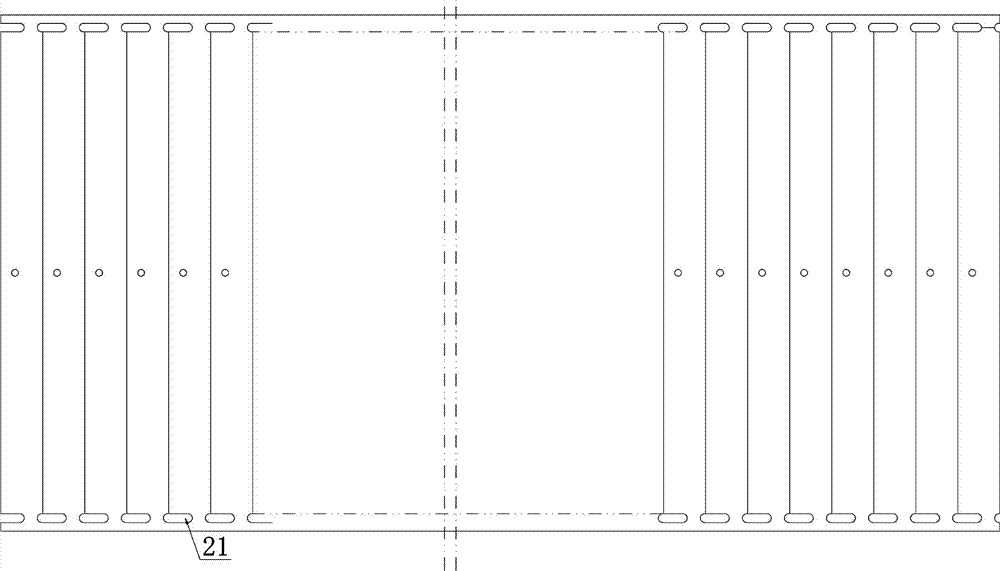

[0039] Such as Figure 4 , Figure 5 As shown, the blade cylinder 2 includes a cylinder composed of a plurality of cylinder units; Figure 6 As shown, each cylinder unit includes a circumferential member 23, and the circumferential member 23 is provided with blades 22 arranged radially along the blade cylinder 2; one end of the circumferential member 23 is provided with a folded structure 24, such as Figure 7 shown; or the two ends of the circumferential member 23 are respectively provided with folding structures 24, as Figure 8 , Figure 9 Shown; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com