Electromagnetic type two freedom degree semi-active vibration absorber

A degree of freedom, semi-active technology, applied in the field of vibration absorbers, can solve the problem that electromagnetic actuators cannot meet the application, and achieve the effect of reducing the number of vibration absorbers, simplifying control links and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

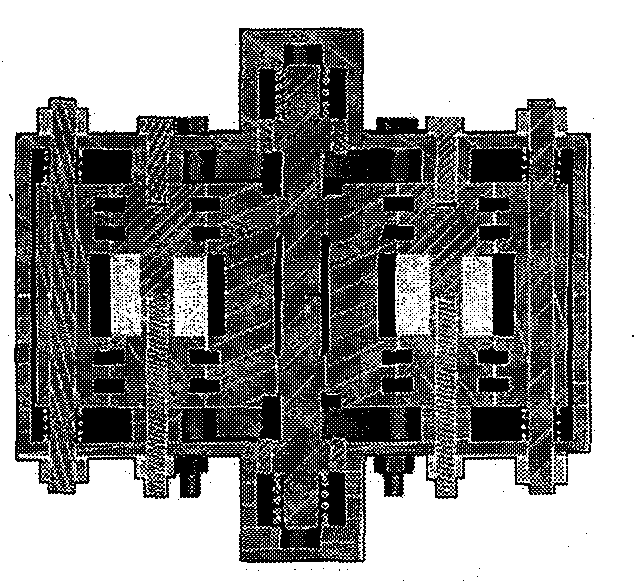

Image

Examples

Embodiment Construction

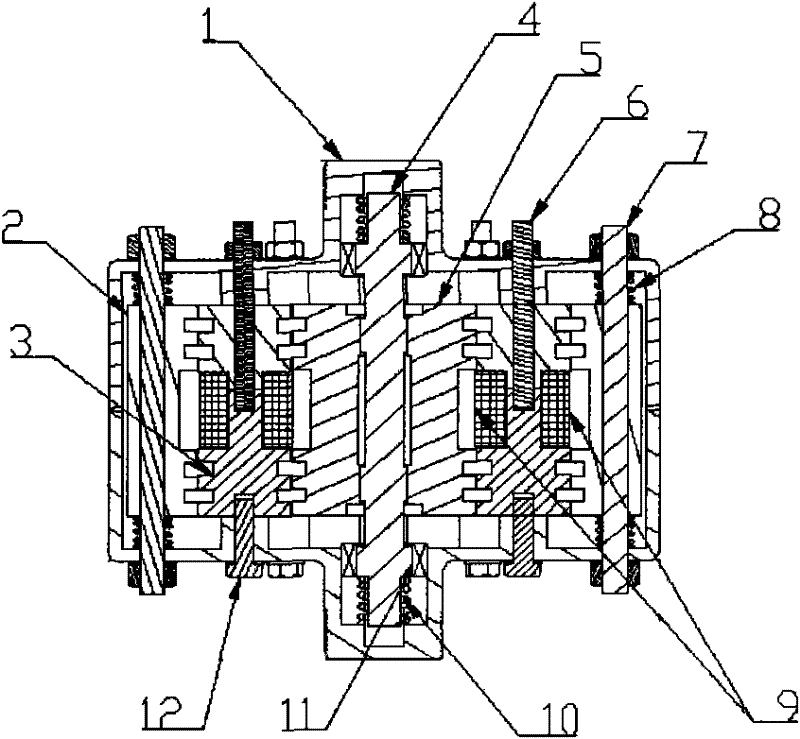

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

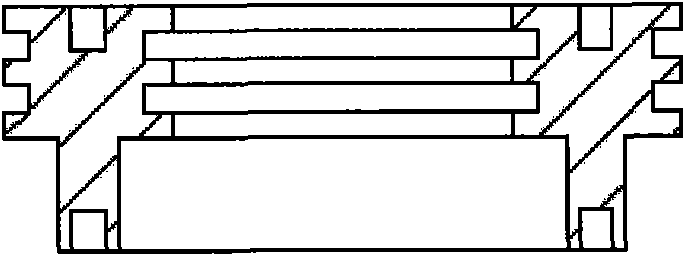

[0025] combine Figure 1-14 , the present invention includes a stator 3, a first mover 5, a second mover 2 and an excitation coil 9, the first mover 5 is connected to the lower end cover 1 through a linear bearing 11 and a mechanical spring 10; the first mover 5 wears four Both ends of the shaft are connected by springs; the first mover 5 and the second mover 2 can move freely in the axial direction relative to the end cover 1 and the stator 3 . There must be a suitable small gap between the stator 3 and the mover. Two excitation coils 9 inside and outside are installed on the stator 3. The working surfaces of the stator 3, the first mover 5 and the second mover 2 are evenly distributed along the axial direction with tooth widths, The tooth pitch and the number of teeth are equal to the ring gear, the stator 3 is an inner and outer double ring gear, the first mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com