Anti-glare diffusion plate with low light loss and preparation method and application thereof

A diffuser and anti-glare technology, applied in the field of lighting, can solve the problems of glare discomfort, permanent damage light transmittance and light diffusivity, etc., and achieve the effect of high light energy utilization efficiency, high transmittance and high diffusivity

Active Publication Date: 2013-07-24

广东亮美集照明科技有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide a high light diffusivity and light transmittance according to the glare discomfort or even permanent damage to human eyes caused by existing high-power white light LEDs and the contradiction between light transmittance and light diffusivity. It can also eliminate the glare discomfort and damage caused by high color temperature directional strong light to the human eye. Anti-glare and low light loss diffuser

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0026] The present invention is further explained below in conjunction with the examples, but the examples do not limit the present invention in any form.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Login to View More

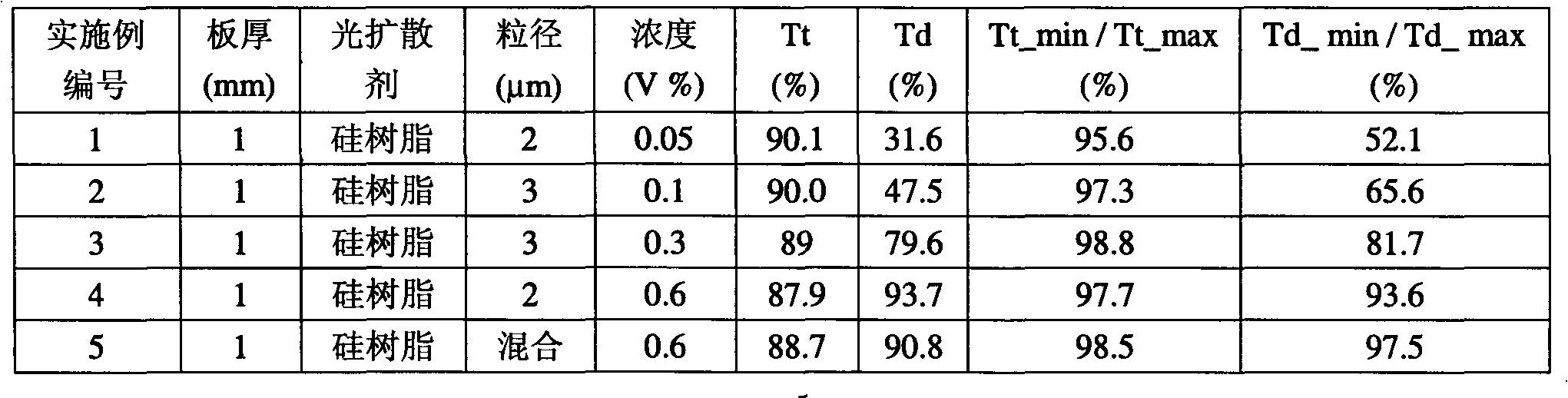

Abstract

The invention discloses an anti-glare diffusion plate with low light loss and a preparation method and application thereof. The diffusion plate is formed by mono-dispersing and filling organic silicon resin microsphere powder with volume percentage of 0.05-2% in optics grade polymethyl methacrylate matrices. The diffusion plate has the high scattering and low light loss characteristics, has lightsource illumination color rendering property being not likely to change, can be used in the high-power LED illumination fields, such as indoor and outdoor LED lamps, planar illumination, art illumination, soft illumination or LED-TV direct liquid-crystal backlight illumination, obtain the illumination effect of uniform brightness, eliminate uncomfortable glare and damage caused by directional hard light with high color temperature on the human eyes and improve the optical efficiency and illumination quality and has broad application prospect.

Description

technical field [0001] The invention relates to the lighting field, in particular to an anti-glare and low-light-loss diffusion plate, a preparation method and application thereof. Background technique [0002] In the field of lighting engineering, in order to obtain uniform and soft lighting effects, light diffusion (light scattering) materials and technologies have been widely used. These techniques can be broadly divided into two categories: area scattering and volume scattering. Surface scattering technology includes surface frosting, embossing, making microprisms, powder spraying, coating, etc.; volume scattering technology refers to the process of filling light diffusing agents in glass or plexiglass. Light diffusing agent refers to the transparent ceramic powder or organic resin powder that is immiscible with the matrix material, or the immiscible transparent plastic is made into a plastic alloy by the method of physical blending. scattering. [0003] For light-sca...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G02B5/02F21V5/00C08L33/12C08L83/04

Inventor 唐振方叶勤栗万里

Owner 广东亮美集照明科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com