Rolling mill work roll shifting device and safety bolt component thereof

A technology of safety bolts and work rolls, which is applied in the safety equipment of rolls, metal rolling stands, metal rolling mill stands, etc. The axial force cannot be unloaded, etc., to achieve the effect of simple structure, improved anti-rotation function, and equipment repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

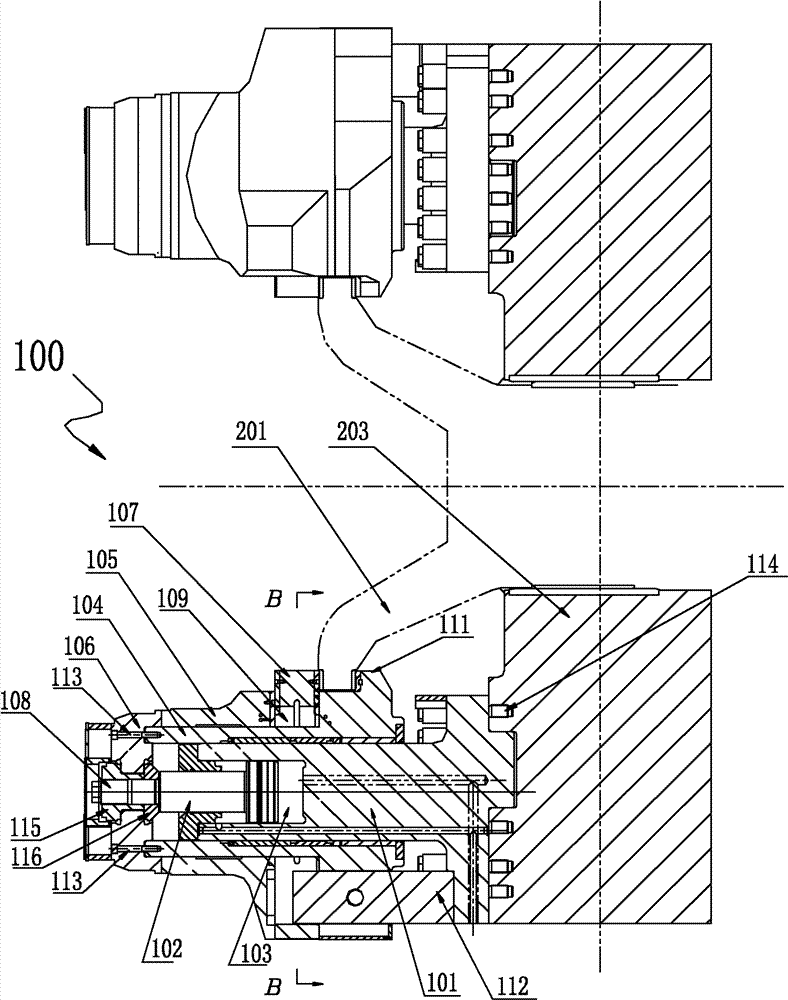

[0046] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

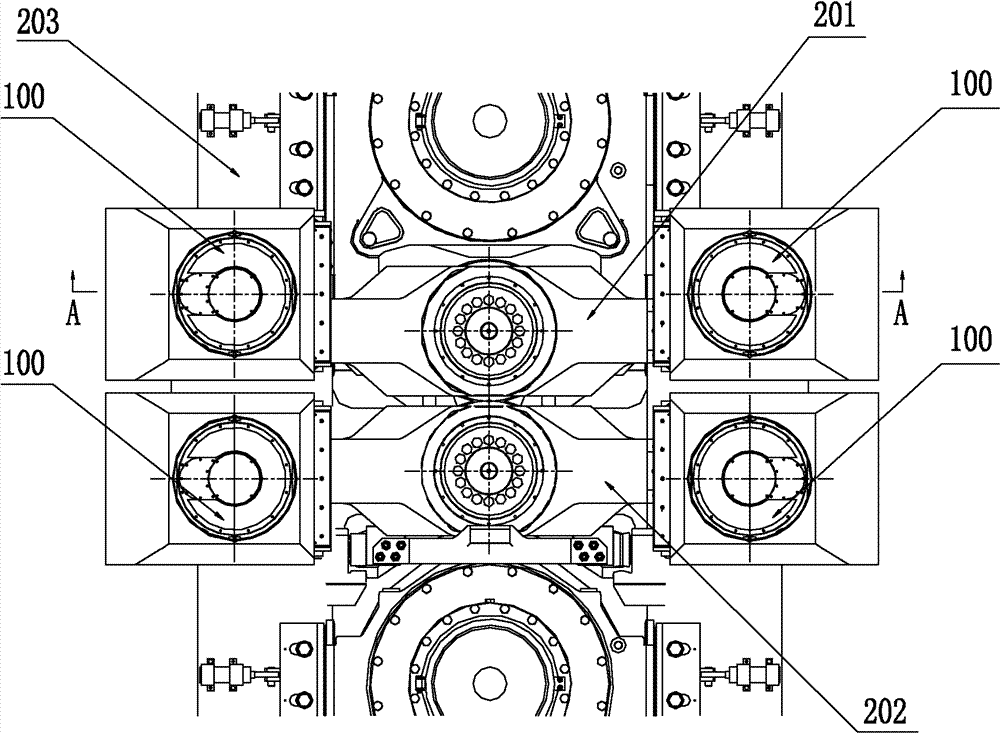

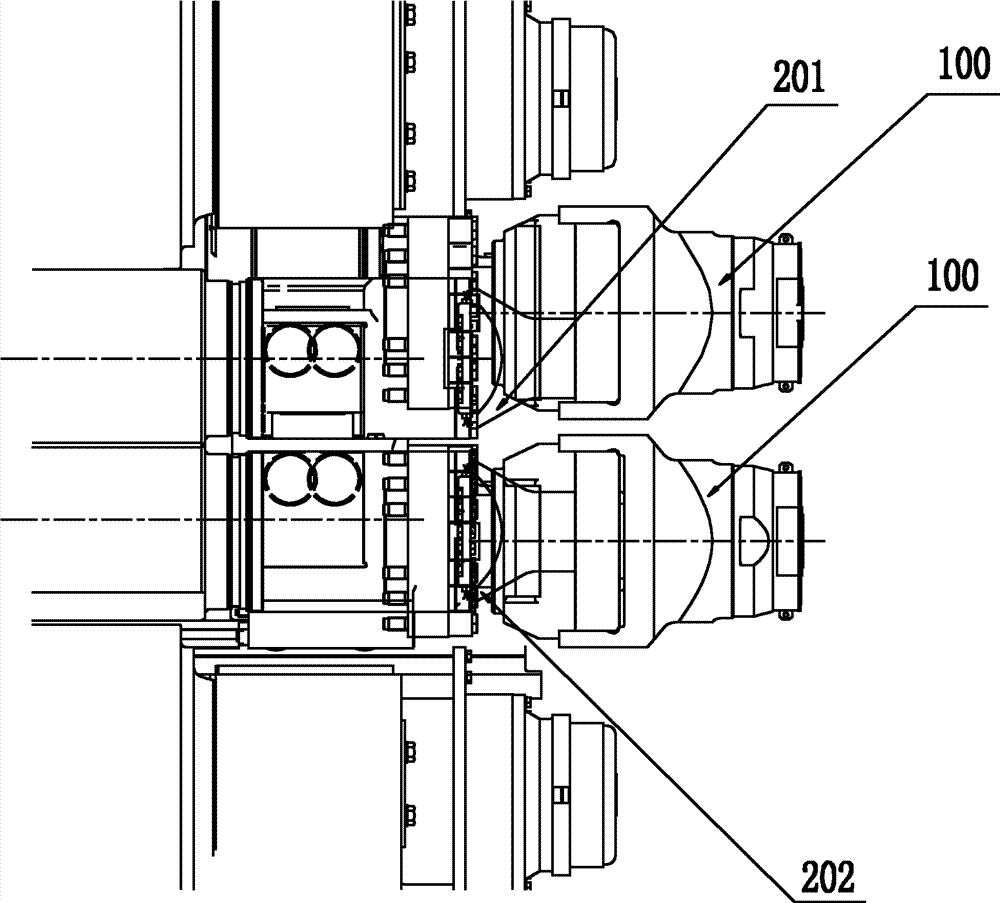

[0047] At least two work roll shifting devices of the rolling mill of the present invention are fixed symmetrically on both sides of the axis of the work roll of the rolling mill, on the frame on the operating side of the rolling mill, and connected with the wing-shaped ends of the work roll chocks. The roll shifting device of the present invention comprises: a roll shifting hydraulic cylinder, one end of the roll shifting hydraulic cylinder is fixed on the frame of the rolling mill, and a piston rod protrudes from the other end of the roll shifting hydraulic cylinder; Assembly, which can clamp the end of the bearing seat, the roll shifting moving assembly can be slidably set on the outer wall of the roll shifting hydraulic cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com