High verdet constant magnetic optic glass and preparation method thereof

A magneto-optical glass and constant technology, applied in the field of high Verdet constant magneto-optic glass and its preparation, can solve the problems of limited application range, immature technology, and inability to form complex shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

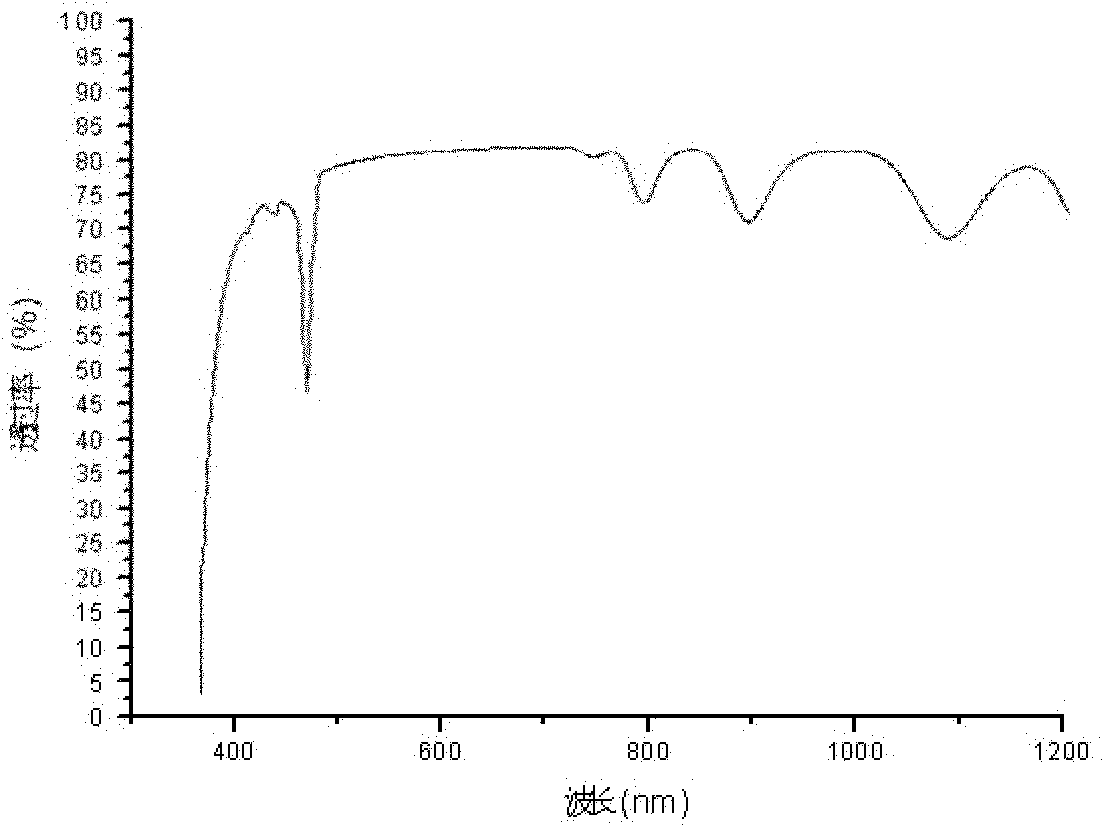

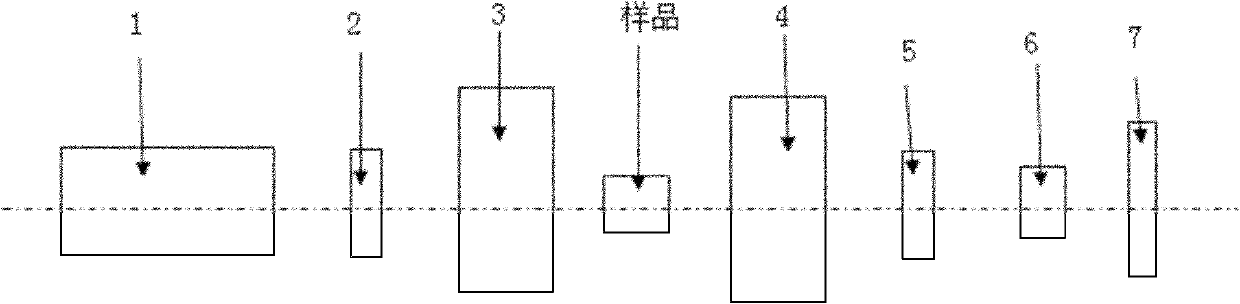

Image

Examples

Embodiment 1

[0020] Weigh and mix the raw materials according to the raw materials and molar ratios described in Example 1, and then when the temperature in the silicon-molybdenum rod electric furnace rises to 1250°C, add the raw materials to the platinum crucible one by one, then continue to heat up to 1350°C, and stir for 3 After hours, the furnace is cooled to 1250°C and poured into a mold for annealing.

Embodiment 2

[0022] Weigh and mix the raw materials according to the raw materials and molar ratios described in Example 2 above. Then, when the temperature in the silicon-molybdenum rod electric furnace rises to 1250°C, the raw materials are added to the platinum crucible one by one, and the temperature is continued to rise to 1355°C and stirred 3.2 After hours, the furnace is cooled to 1260°C and poured into a mold for annealing.

Embodiment 3

[0024] Weigh and mix the raw materials according to the raw materials and molar ratios described in Example 3 above. Then, when the temperature in the silicon-molybdenum rod electric furnace rises to 1250°C, the raw materials are added to the platinum crucible one by one, and then the temperature is increased to 1360°C and stirred for 3.5 After hours, the furnace was cooled to 1270°C and poured into a mold for annealing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com