Light-emitting diode lamp bulb capable of performing forced convection and cooling

A technology of LED bulbs and forced convection, which is applied to lighting and heating equipment, components of lighting devices, emergency protection devices for automatic disconnection, etc. Large and other problems, to achieve the effect of broad promotion and application prospects, long overall service life, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The LED light bulb for forced convection heat dissipation of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

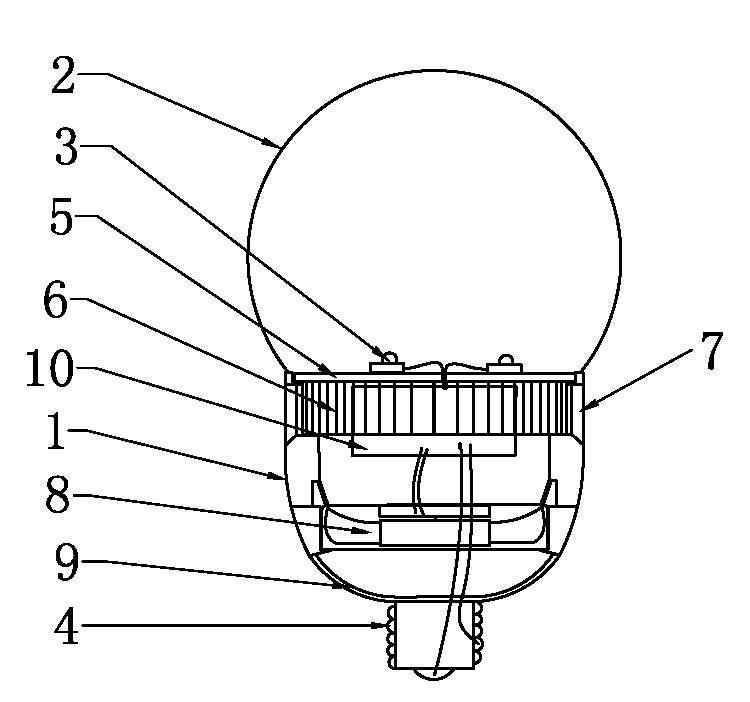

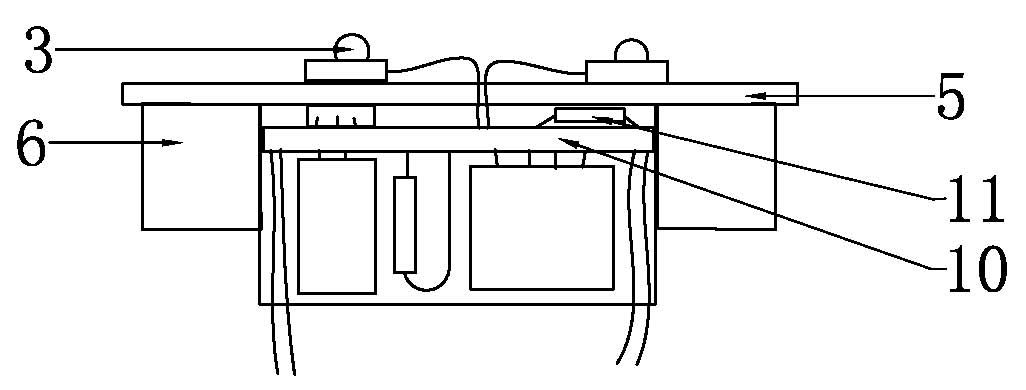

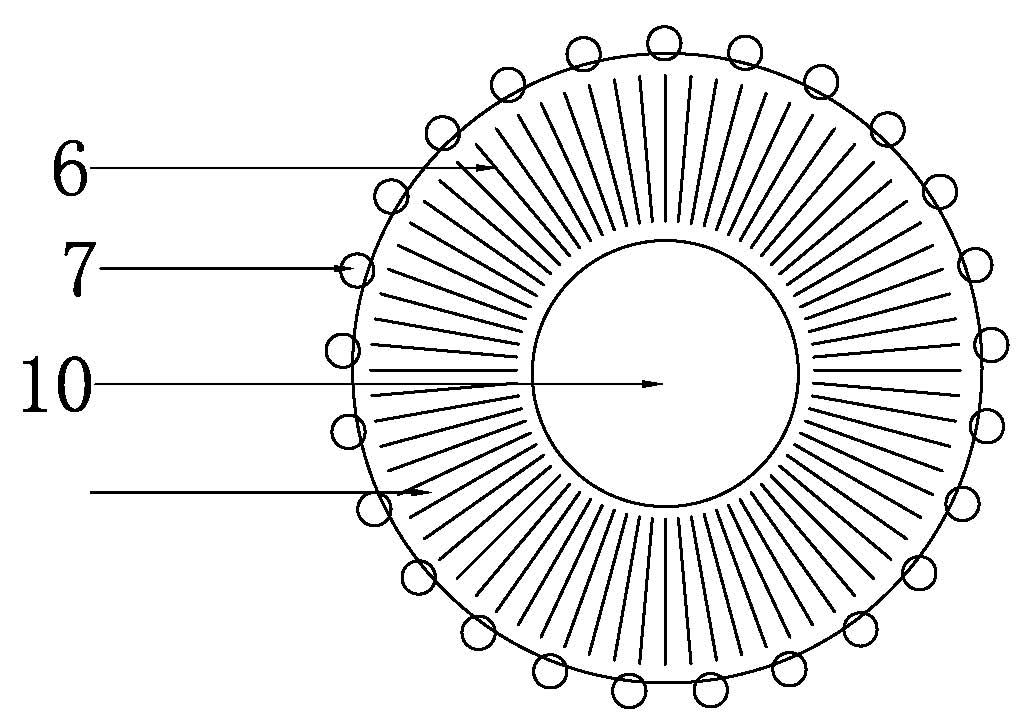

[0014] As shown in the figure, the LED light bulb with forced convection heat dissipation of the present invention includes a housing 1, a lampshade 2 is arranged on the upper end of the housing, an LED lamp bead 3 is installed in the lampshade, and a lamp cap 4 is arranged at the center of the lower end of the housing; the upper end of the inner cavity of the housing A lamp bead substrate 5 is provided, and the LED lamp beads 3 in the lampshade are installed on the upper surface of the lamp bead substrate 5, and a plurality of heat sinks 6 are arranged on the lower surface of the lamp bead substrate 5, and the housing wall plate around the heat sink is provided with An air outlet grille 7; an axial flow fan 8 is installed in the middle of the inner cavity of the housing, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com