Indirect internally reforming solid oxide fuel cell and a method of stopping same

A solid oxide and fuel cell technology, which is applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve SOFC performance degradation and other problems, and achieve the effect of preventing oxidation degradation and reliable conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, embodiments of the present invention will be described using the drawings, but the present invention is not limited thereto.

[0053] [Indirect Internal Conversion SOFC]

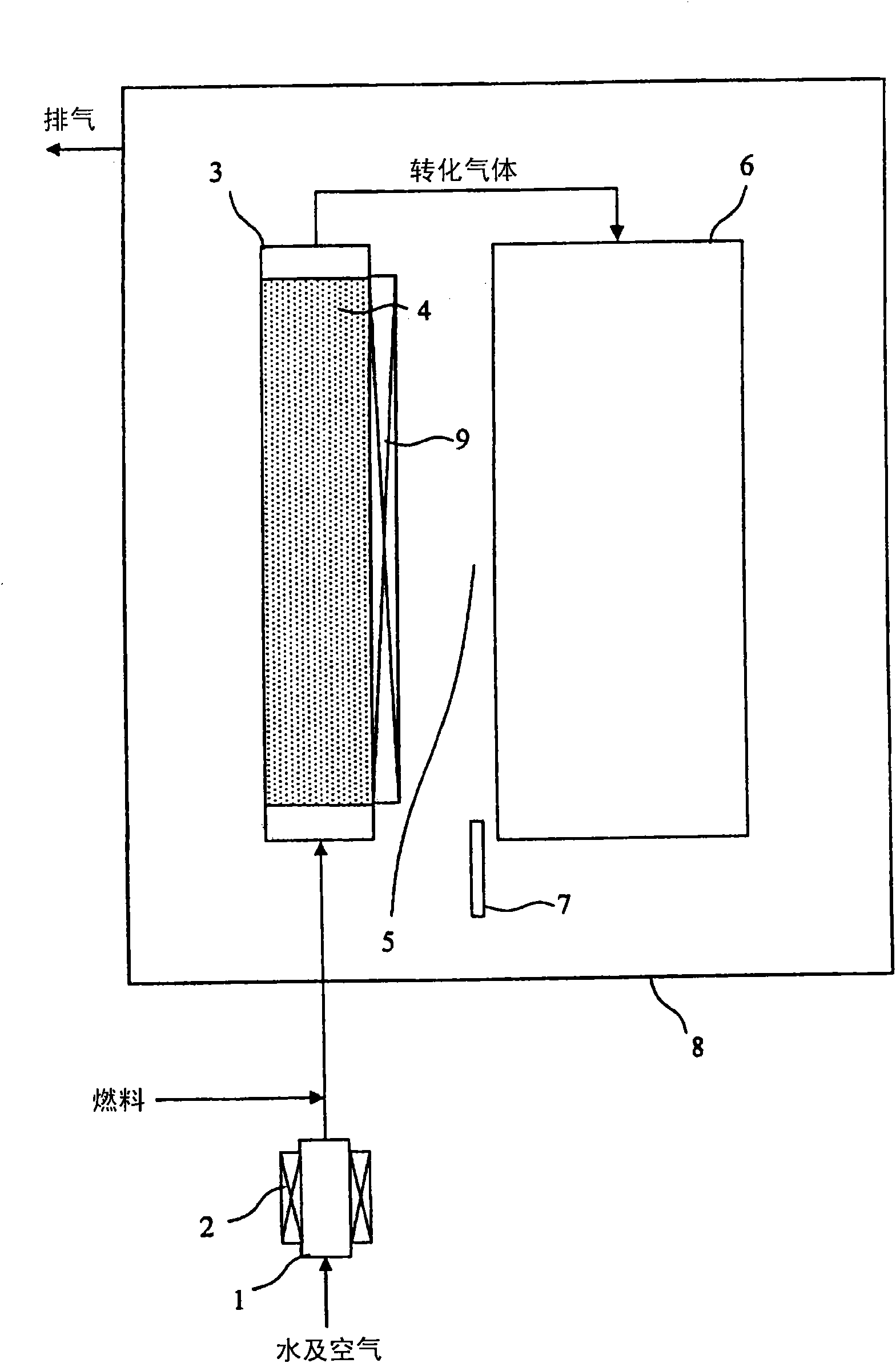

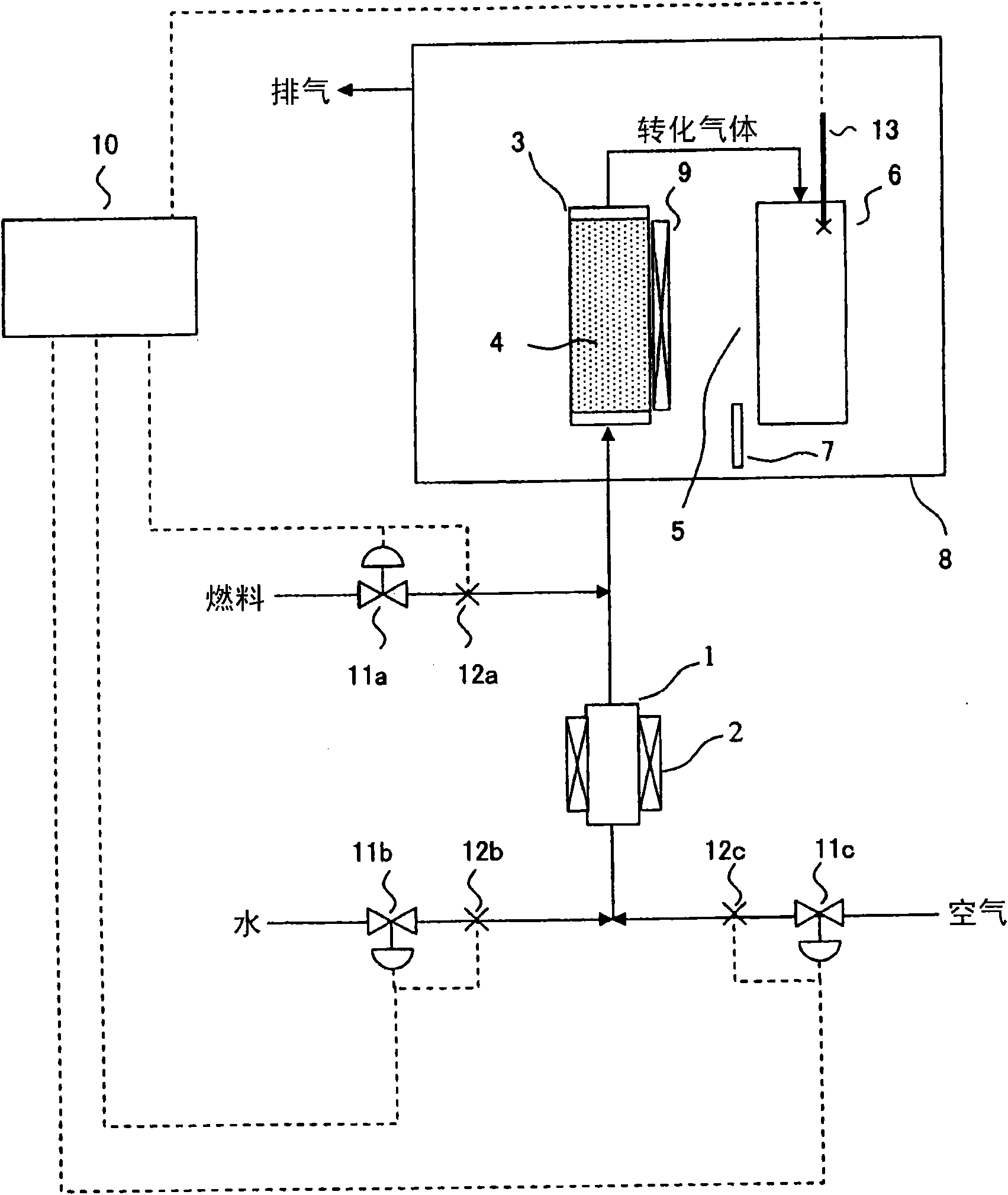

[0054] figure 1 , schematically shows one mode of the indirect internal conversion type SOFC that can implement the present invention.

[0055] The indirect internal reforming SOFC has a reformer 3 for reforming a hydrocarbon-based fuel to produce a reformed gas (hydrogen-containing gas). The reformer has a reforming catalyst layer 4 .

[0056] The indirect internal reforming SOFC has an SOFC 6 for generating power using the reformed gas, and a combustion zone 5 for burning anode off-gas discharged from the SOFC (especially its anode).

[0057] The indirect internal reforming SOFC has a case 8 for accommodating a reformer, a solid oxide fuel cell, and a combustion region.

[0058] The indirect internal transformation type SOFC refers to the shell 8 (module container) 8 and the equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com