Self-suction liquid soap feeding device

A self-priming, soap solution technology, applied in water supply devices, indoor sanitary piping devices, brackets or dispensers, etc., can solve problems such as insufficient hand washing, waste, poor operation, etc. The effect of stable liquid output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

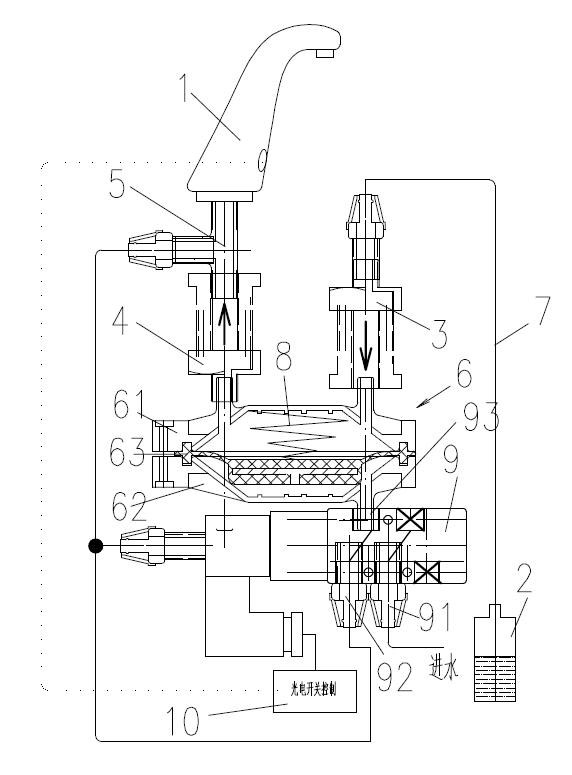

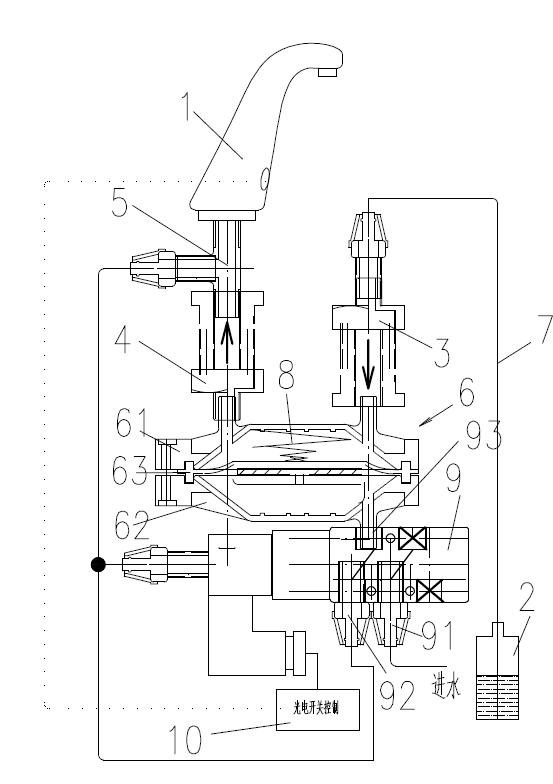

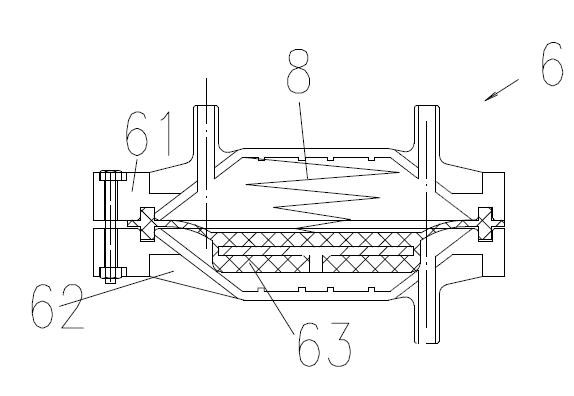

[0016] Such as figure 1 As shown, in this specific embodiment, the self-priming soap liquid supply device includes a liquid supply tap 1, a soap liquid box 2, a liquid suction check valve 3, a liquid discharge check valve 4, a mixing joint 5, and a liquid suction device. 6 and its suction controller. The liquid aspirator 6 can adopt a structure similar to that of a miniature plunger pump, and the plunger rod is pushed by water pressure, but this method is too complicated in structure, and it is easy to drip and leak, which is also not conducive to miniaturization. Such as image 3 As shown, in this specific embodiment, the liquid aspirator 6 includes a liquid suction chamber cover 61 and a water inlet chamber cover 62 that are interlocked with an arched concave cavity, and the liquid suction chamber cover 61 and the water inlet chamber cover An elastic diaphragm 63 is sandwiched between 62 to divide the interior into two sealed cavities. Of course, the concave cavity is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com