Photoresist uniform applying device for integrated circuit chip in solar cell panel

A solar panel and integrated circuit technology, applied in the field of solar energy, can solve the problems of uneven flow of glue, increase intelligence, and the inability to change the amount of glue, so as to achieve the effect of uniform glue application, increase intelligence, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

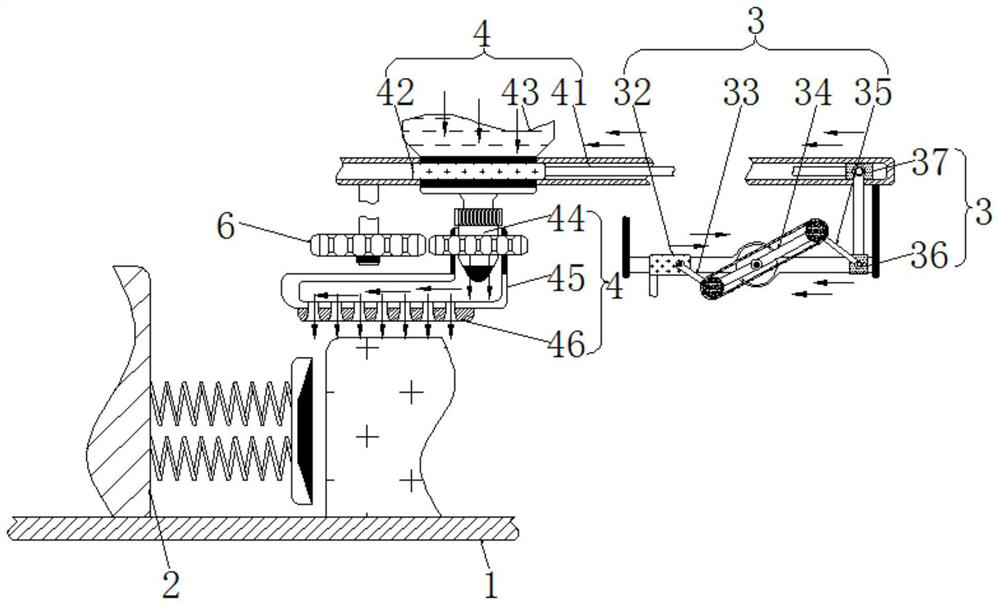

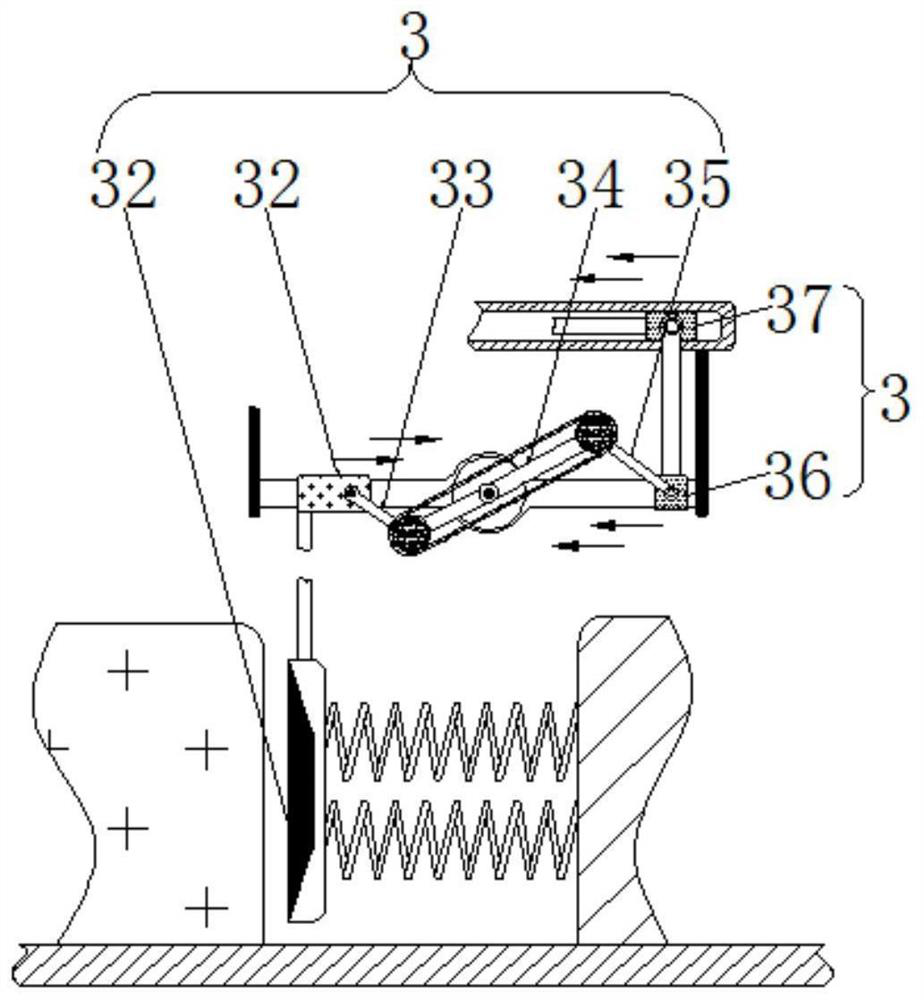

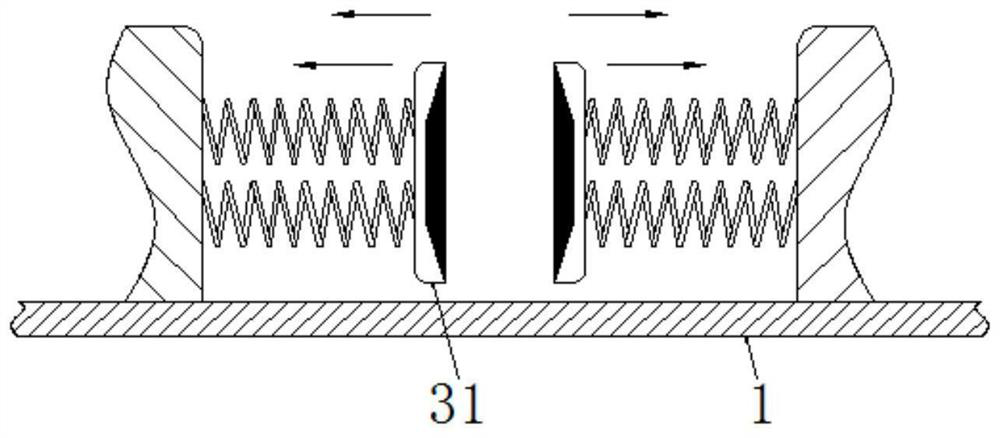

[0023] see Figure 1-2 , a photoresist uniform coating device for an integrated circuit chip in a solar panel, comprising a limit mechanism 3, the limit mechanism 3 includes a limit plate 31, two limit plates 31 are provided, two limit plates 31 The specifications are the same, and they are distributed symmetrically with reference to the center line of the support plate 1. At the same time, a chute is opened on the surface of the limit plate 31, and a spring is arranged between the limit plate 31 and the fixing seat 2. The position plate 31 automatically clamps and limits the wafers being processed to ensure the stability of the wafer processing. At the same time, the limit plate 31 can simultaneously limit the positions of wafers with different radii, improving the intelligence of the device when it is used. The movement of the limiting plate 31 drives the first set of rods 32 to move synchronously, the first set of rods 32 is socketed above the limiting plate 31, and the sur...

Embodiment 2

[0026] see figure 1 , a photoresist uniform coating device for integrated circuit chips in solar panels, and also includes a control mechanism 4, the left end of the slider 37 is welded with a push plate 41, and the end of the push plate 41 away from the slider 37 is clamped with a stop Plate 42, the size of the baffle 42 and the size of the liquid outlet 44 are adapted to each other, and at the same time, a channel is opened inside the scraper 45, and the opening size of the liquid outlet 44 is changed by the movement of the baffle 42, thereby changing the time of gluing. The amount of glue output can improve the intelligence of the device when applying glue, and reduce the waste of glue. The top of the baffle plate 42 is fixedly connected with a liquid storage tank 43, and the inside of the liquid storage tank 43 is provided with a liquid outlet 44. The liquid outlet The outer surface of 44 is sleeved with a scraper 45, and the bottom of the scraper 45 is provided with a spo...

Embodiment 3

[0029] see Figure 1-4 , a photoresist uniform coating device for an integrated circuit chip in a solar panel, comprising a limit mechanism 3, the limit mechanism 3 includes a limit plate 31, two limit plates 31 are provided, two limit plates 31 The specifications are the same, and they are distributed symmetrically with reference to the center line of the support plate 1. At the same time, a chute is opened on the surface of the limit plate 31, and a spring is arranged between the limit plate 31 and the fixing seat 2. The position plate 31 automatically clamps and limits the wafers being processed to ensure the stability of the wafer processing. At the same time, the limit plate 31 can simultaneously limit the positions of wafers with different radii, improving the intelligence of the device when it is used. The movement of the limiting plate 31 drives the first set of rods 32 to move synchronously, the first set of rods 32 is socketed above the limiting plate 31, and the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com