Milk nail polish remover

A technology of nail polish remover and milk, which is applied in manicure, cosmetics, pedicure, etc. It can solve the problems of human health damage, organic solvent smell, whitening, etc., and achieve the effect of quick removal and no irritating smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

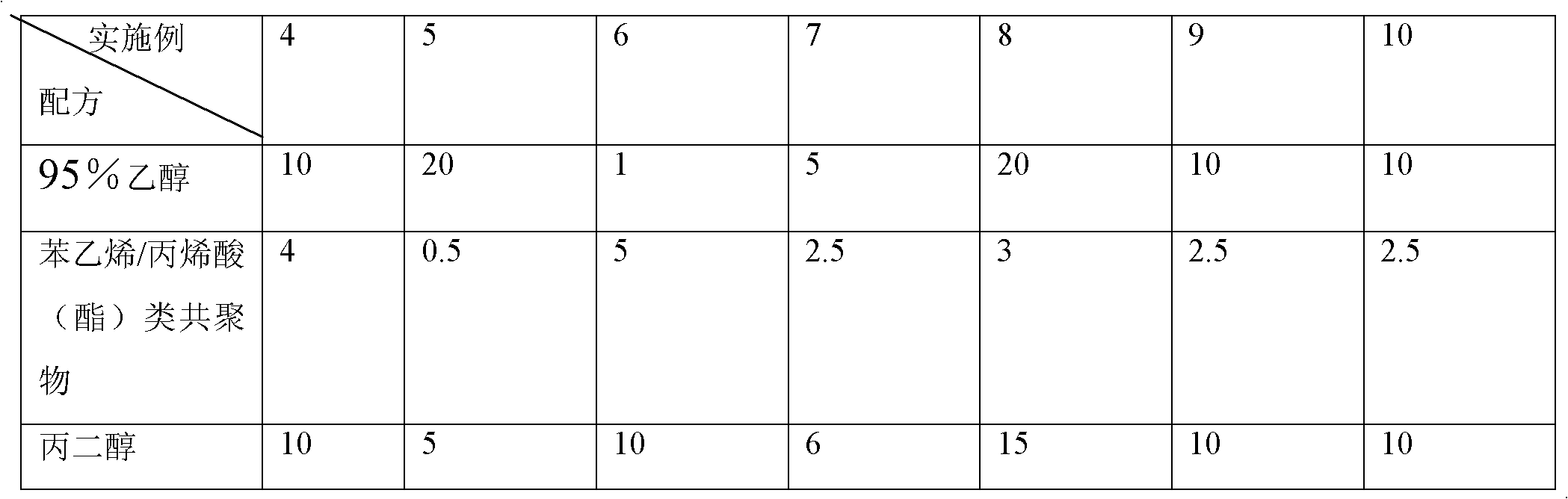

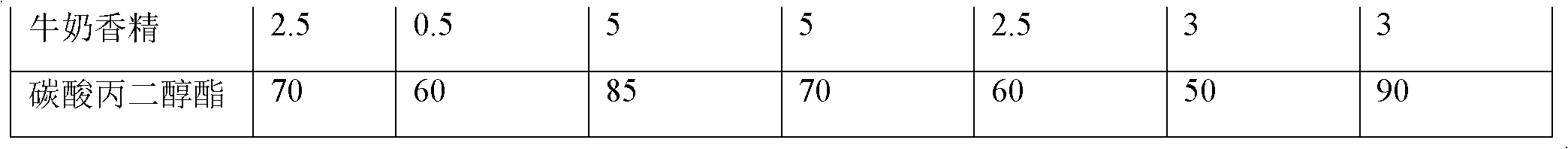

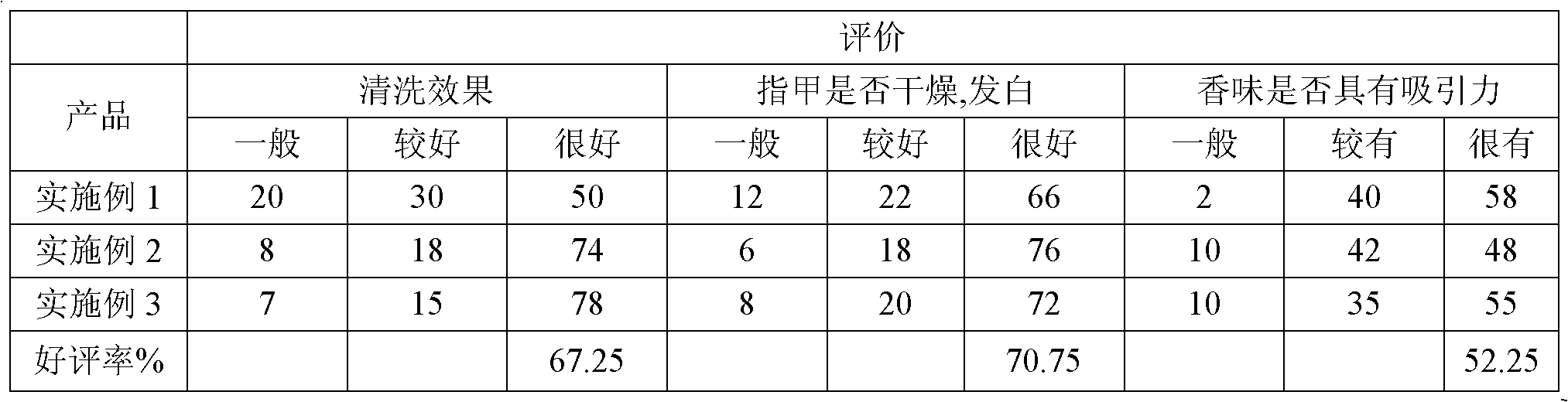

Examples

Embodiment 1

[0021] Weigh each component by weight as follows:

[0022] 95% ethanol 15g,

[0023] Styrene / acrylic acid (ester) copolymer 3g;

[0024] Propylene glycol 5g;

[0025] Milk essence 2g;

[0026] Propylene glycol ester 75g.

[0027] The nail polish remover preparation method is as follows:

[0028] (1) Fully stir ethanol and styrene / acrylic acid (ester) copolymer at 1000RPM until there are no particles, add propylene glycol to the above mixture at 1000RPM and stir evenly; add milk essence and acid in turn at 500RPM Propylene glycol ester is mixed and stirred evenly;

[0029] (2) Filter the mixture prepared in step (1) with a 400-mesh filter screen, and fill it after detecting no impurities.

Embodiment 2

[0031] Weigh each component by weight as follows:

[0032] 95% ethanol 10g,

[0033] Styrene / acrylic acid (ester) copolymer 2g;

[0034] Propylene glycol 10g;

[0035] Milk essence 1g;

[0036] Propylene glycol ester 77g.

[0037] The nail polish remover preparation method is as follows:

[0038] (1) Fully stir ethanol and styrene / acrylic acid (ester) copolymer at 1500RPM until there are no particles, add propylene glycol to the above mixture at 800RPM and stir evenly; add milk essence and acid in turn at 500RPM Propylene glycol ester is mixed and stirred evenly;

[0039] (2) Filter the mixture prepared in step (1) with a 400-mesh filter screen, and fill it after detecting that there is no impurity.

Embodiment 3

[0041] Weigh each component by weight as follows:

[0042] Ethanol 20g,

[0043] Styrene / acrylic acid (ester) copolymer sodium 4g;

[0044] Propylene glycol 5g;

[0045] Milk essence 5g;

[0046] Propylene glycol ester 66g.

[0047] The nail polish remover preparation method is as follows:

[0048] (1) Fully stir 95% ethanol and styrene / acrylic acid (ester) copolymerized sodium at 1300RPM until there are no particles, add propylene glycol to component A at 900RPM and stir evenly; add in sequence at 500RPM Mix milk essence and propylene glycol ester and stir evenly;

[0049] (2) Filter the mixture prepared in step (1) with a 400-mesh filter screen, and fill it after detecting no impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com