High-frequency high-voltage switching power supply for electric precipitation

A high-frequency high-voltage, switching power supply technology, applied in the direction of high-efficiency power electronic conversion, power supply technology, electrical components, etc., can solve the problems of high-frequency high-voltage switching power supply design difficulties, etc., and achieve the effect of light weight, high power factor, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

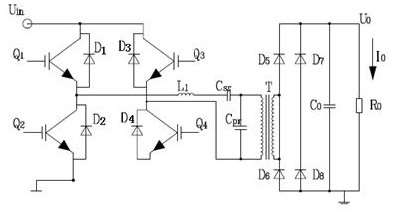

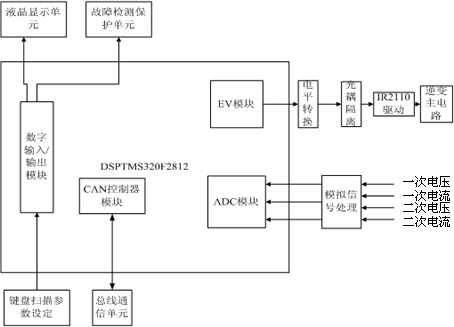

[0013] The system structure of the high-frequency high-voltage switching power supply based on DSP TMS320F2812 is as follows: figure 1 As shown, the main circuit is the input three-phase 380V50Hz AC power supply, which becomes 530V DC voltage through the three-phase rectification filter circuit 1, and then passes through the high-frequency inverter circuit 2 composed of IGBT modules, and the high-frequency pulse transformer 3 is boosted by high-voltage The silicon rectifier stack 4 becomes 72kV high-voltage direct current to the electrostatic precipitator 5; the DSP controller 7 realizes the H-bridge triggering of the high-frequency inverter circuit 2, and the input side of the electrostatic precipitator is connected to 6 pairs of voltage and current detection boards to complete the detection of voltage and current, and the signal Input the DSP controller 7 to adjust the high-frequency inverter circuit 2 through the DSP controller 7, and the DSP controller is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com