Spinning deviation-correcting method for punching-pulling steel bottle tube wall thickness

A steel cylinder tube and deflection correction technology, which is applied to other household appliances, household appliances, applications, etc., can solve the problems that affect the processing quality of the steel cylinder tube body, poor surface roughness inside and outside, uneven wall thickness of the steel cylinder tube body, etc., and reduce the weight of the steel cylinder , product performance improvement, the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

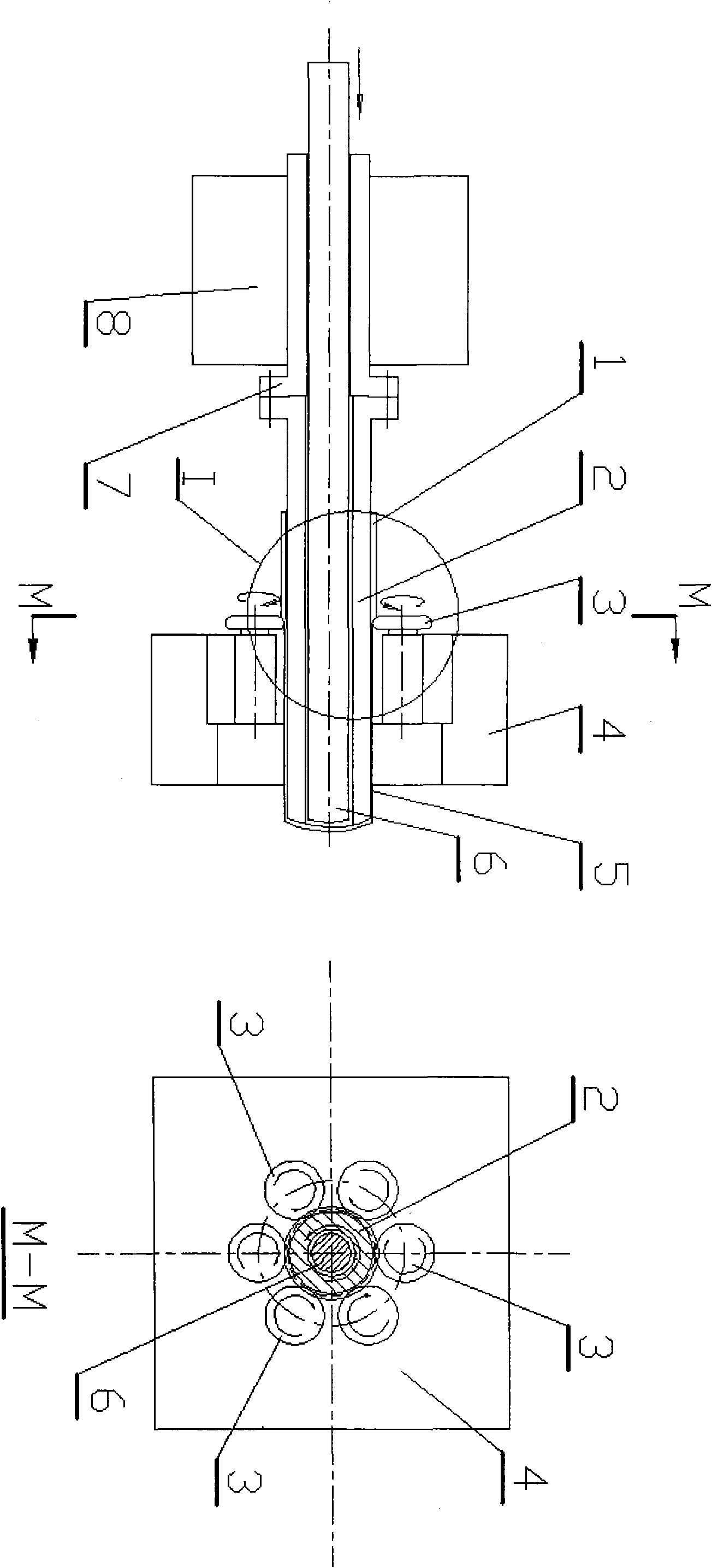

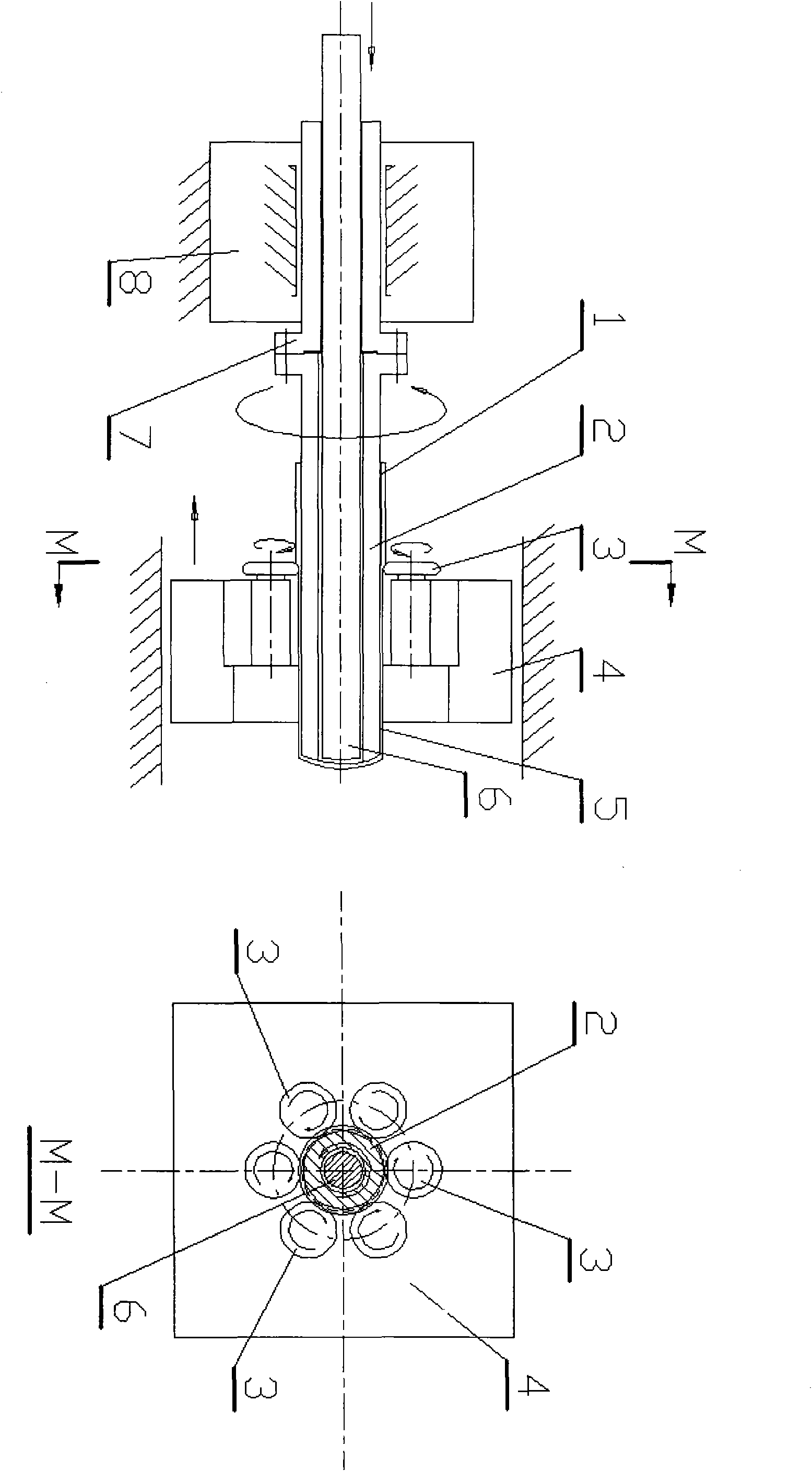

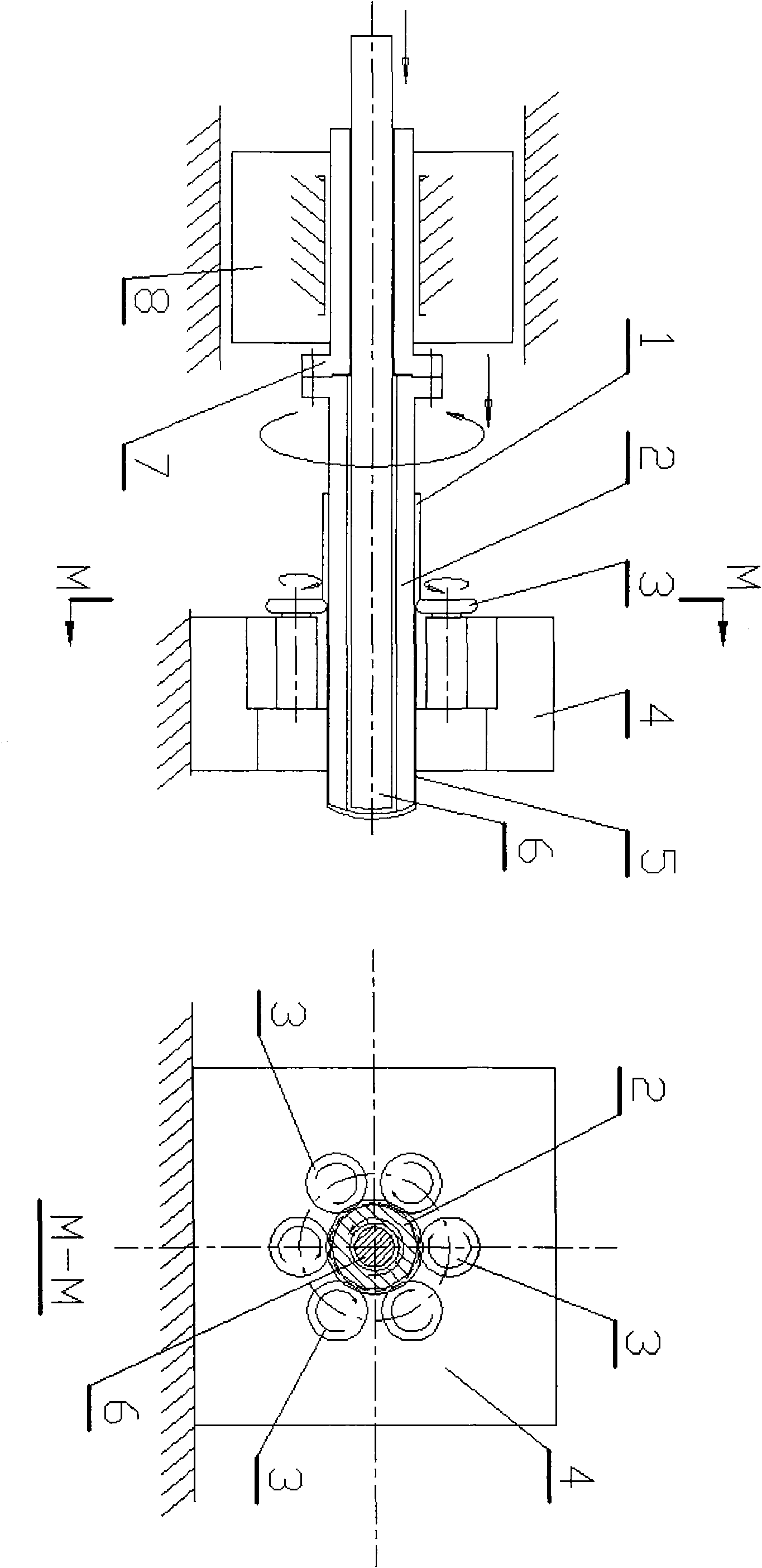

[0018] Embodiment 1 of the present invention such as figure 2 As shown, the steel cylinder blank (1) is put on the mandrel (2) of the internal spinning deformation correction tool, the mandrel (2) is installed on the main shaft (7), and the main shaft (7) is installed on the fixed headstock (8) Among them, it can also be used as a steel cylinder blank (1) for active rotation, the main shaft (7) can only rotate, and is positioned by the bearing in the main shaft box (8) in the axial direction and can withstand the axial force during spinning and deviation correction processing. The spinning wheels (3) are evenly distributed and installed on the spinning wheel fixing seat (4) with the rolling center line as the center. There are six spinning wheels (3) distributed in the figure, and other numbers of spinning wheels (3) can also be evenly distributed. The number of wheels, the spinning wheel (3) can rotate with its own center of rotation, and can bear the axial force and radial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com