Crushing shaft of rubber rubbing and cutting machine

A crushing shaft and cutting machine technology, which is applied in the direction of mechanical material recovery, recycling technology, grain processing, etc., can solve the problems of step 102 wear, high power consumption of crushing, easy damage of flat keys, etc., so as to avoid blockage and improve service life effect on reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

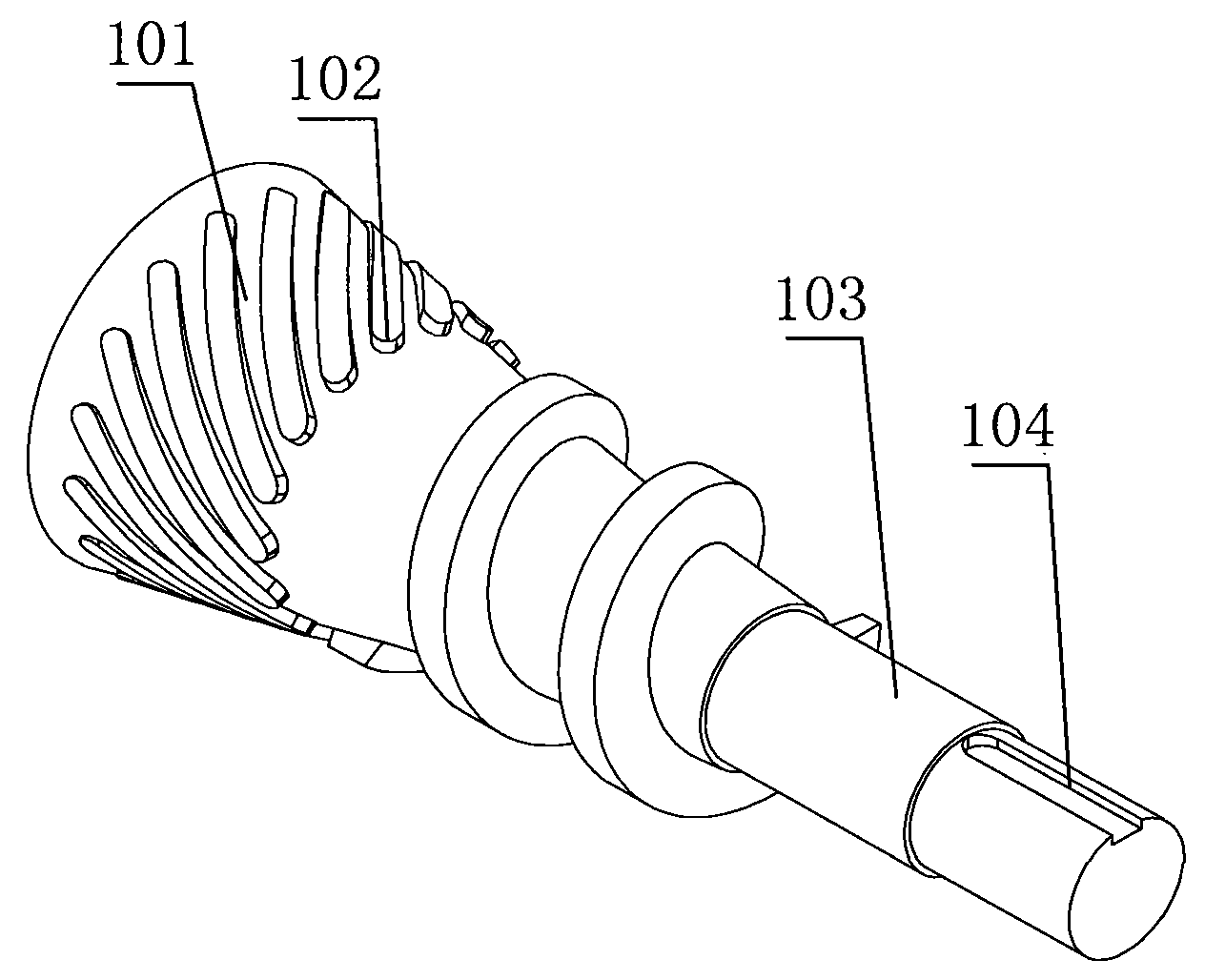

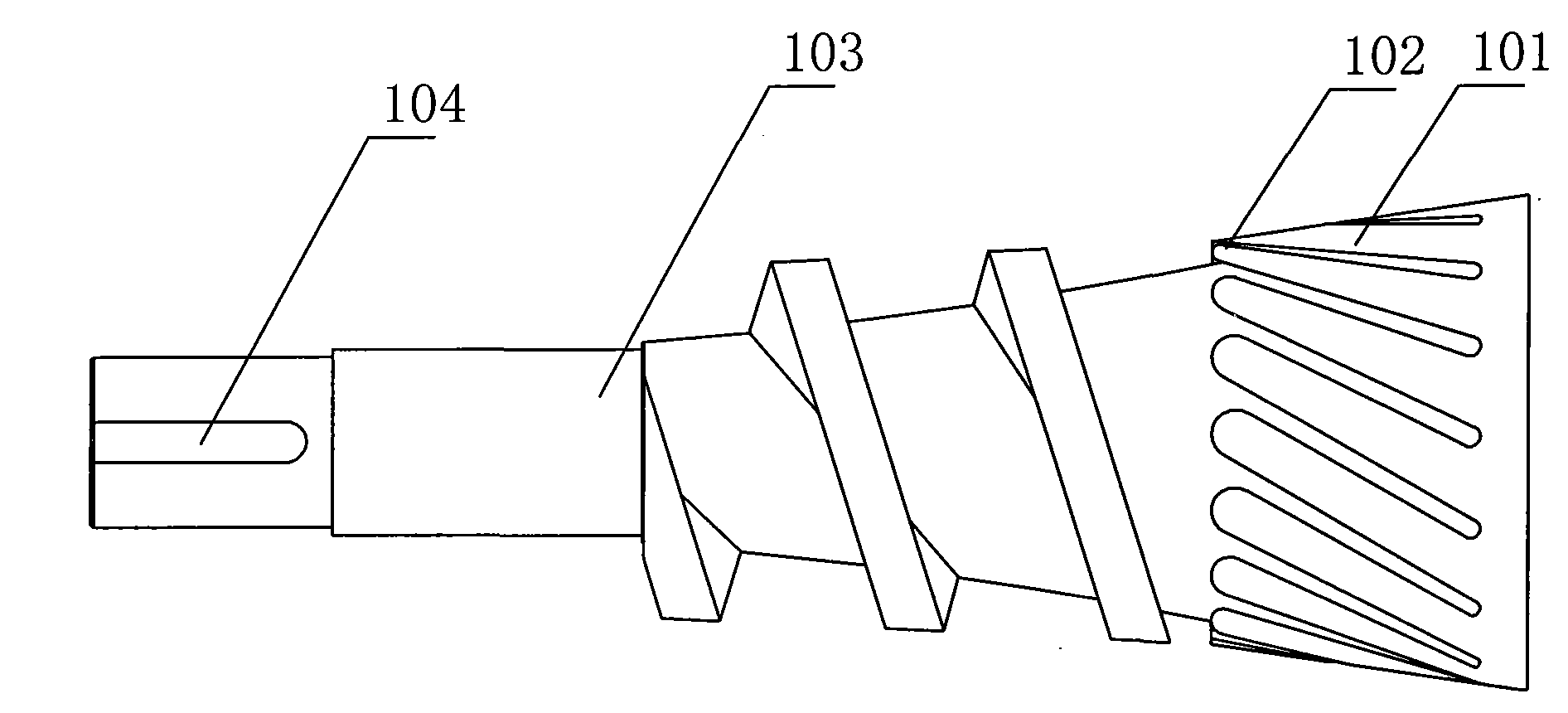

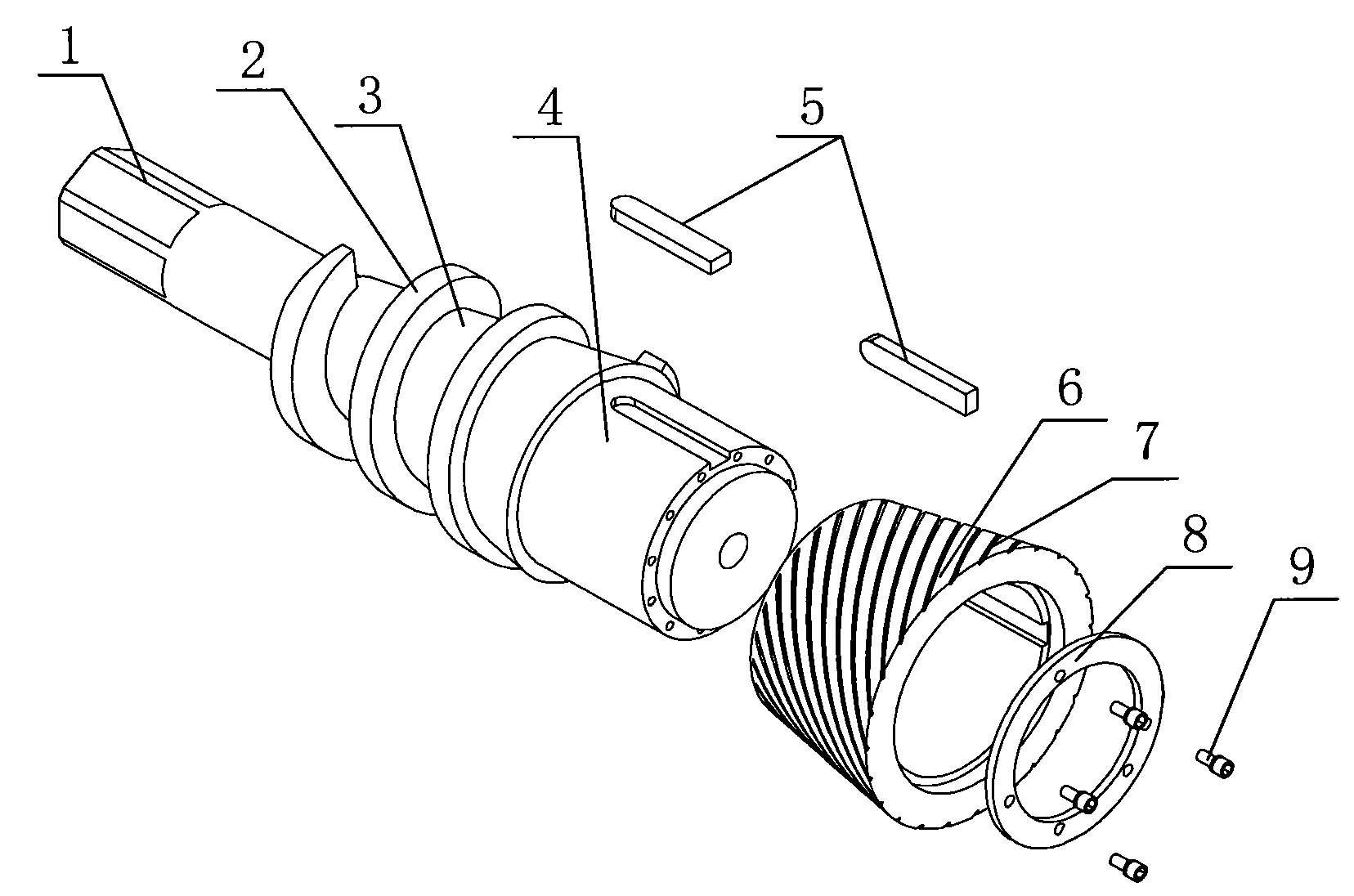

[0016] Such as image 3 , Figure 4 As shown, the crushing shaft outer sleeve 6 and the main shaft 3 of the present invention are separable structures, the rear section of the main shaft 3 is a clamping part 1, the middle part is a screw conveying part 2, and the front part is a knife holder fixing part 4; the clamping part 1 is The hexagonal shaft structure, compared with the flat key structure used in the existing rubbing machine main shaft clamping part, can effectively increase the rotational torque transmitted by the main shaft and prevent the flat key from being sheared and damaged; the outer surface of the screw conveying part 2 in the middle , including the side, top and groove bottom of the helical blade are welded with cemented carbide layer, which can effectively avoid the damage of the helical surface; The split crushing shaf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com