Water and steam pipeline oxygenation control method for power plant

A control method and technology for power plants, applied in pipeline protection, chemical instruments and methods, pipeline anti-corrosion/anti-rust protection, etc., can solve the problem of oxygen content signal lag, oxygen content oscillation in feed water or condensate water, deviation from adjustment target value and other problems, to achieve the effect of fine adjustment of oxygenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

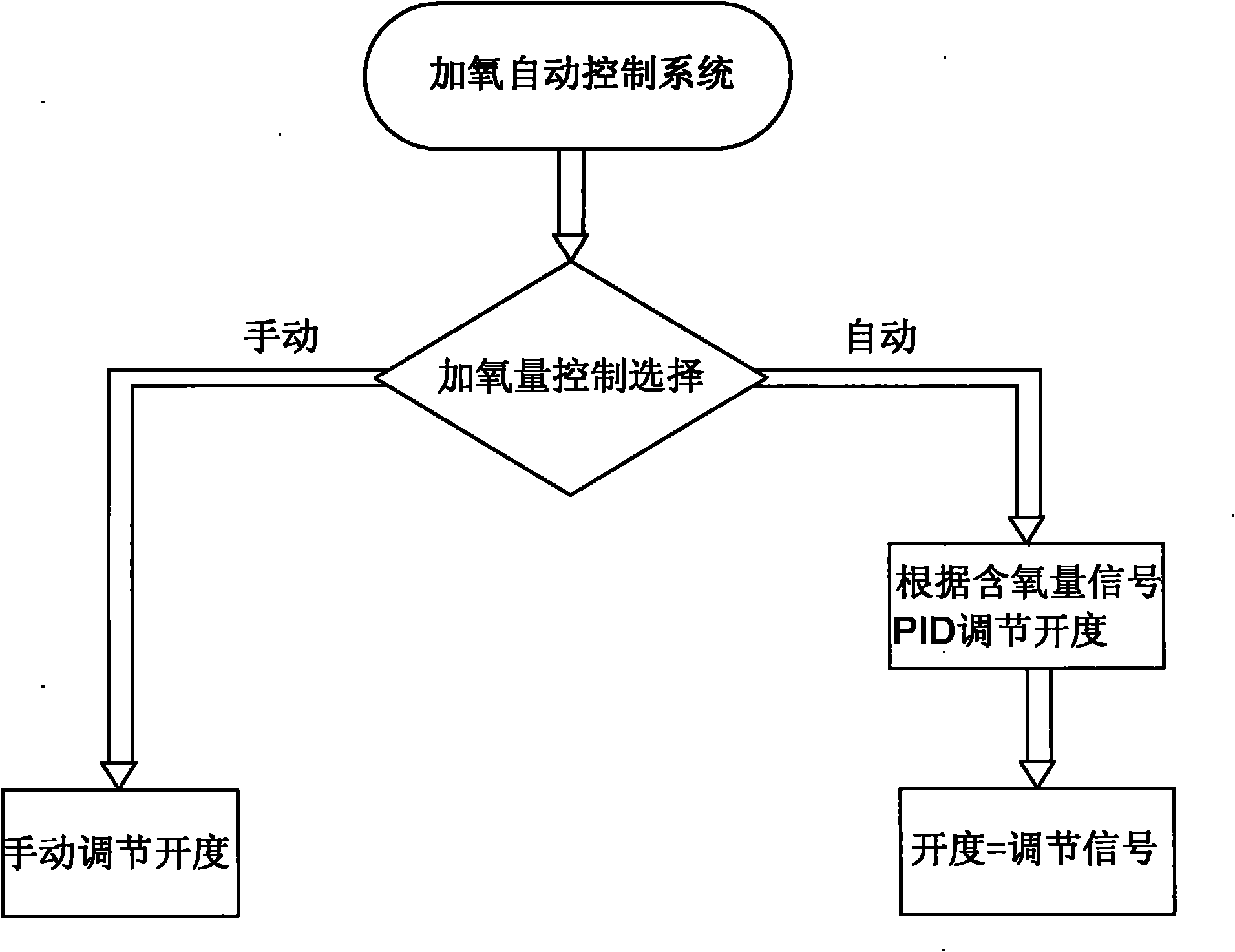

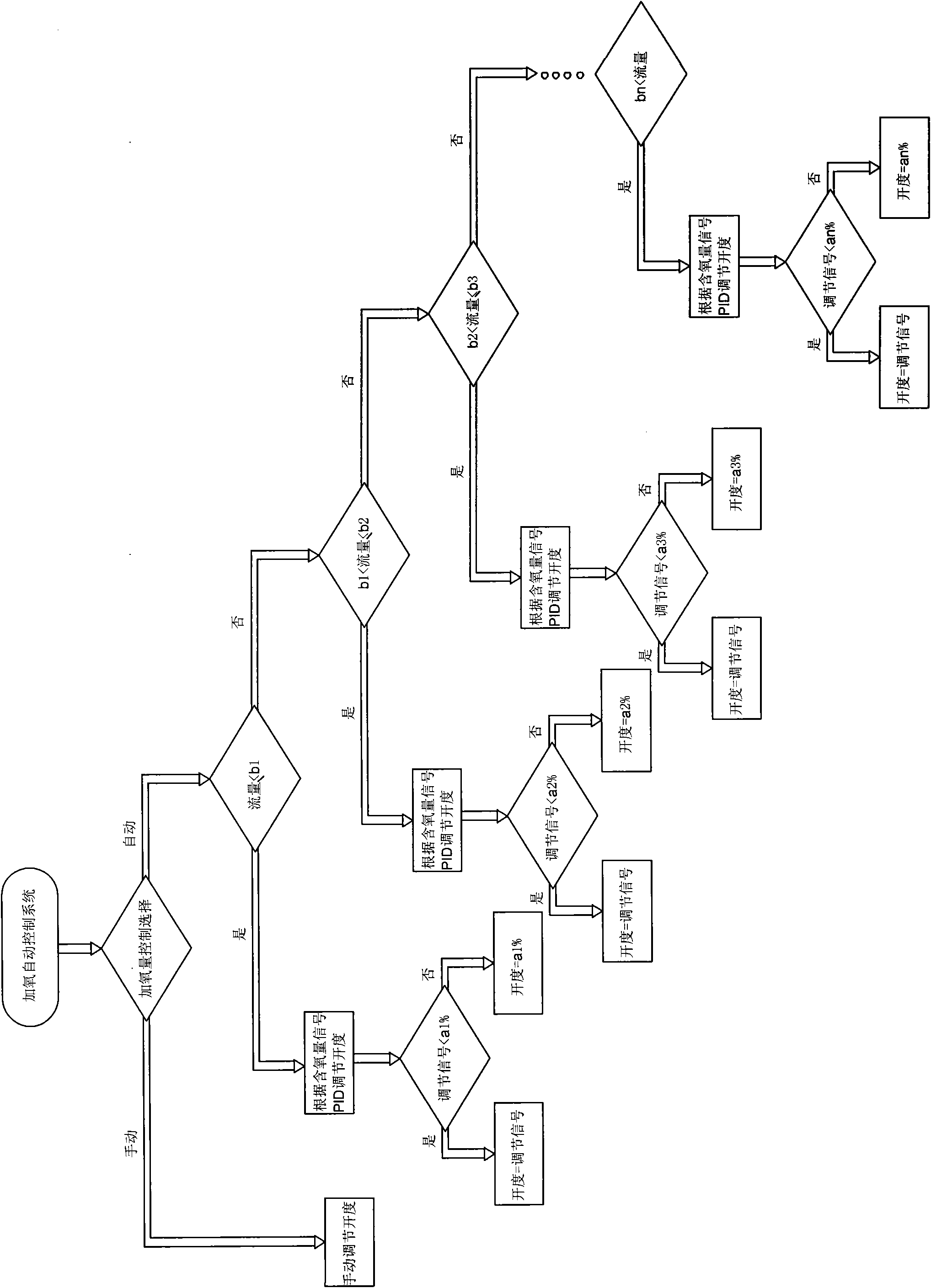

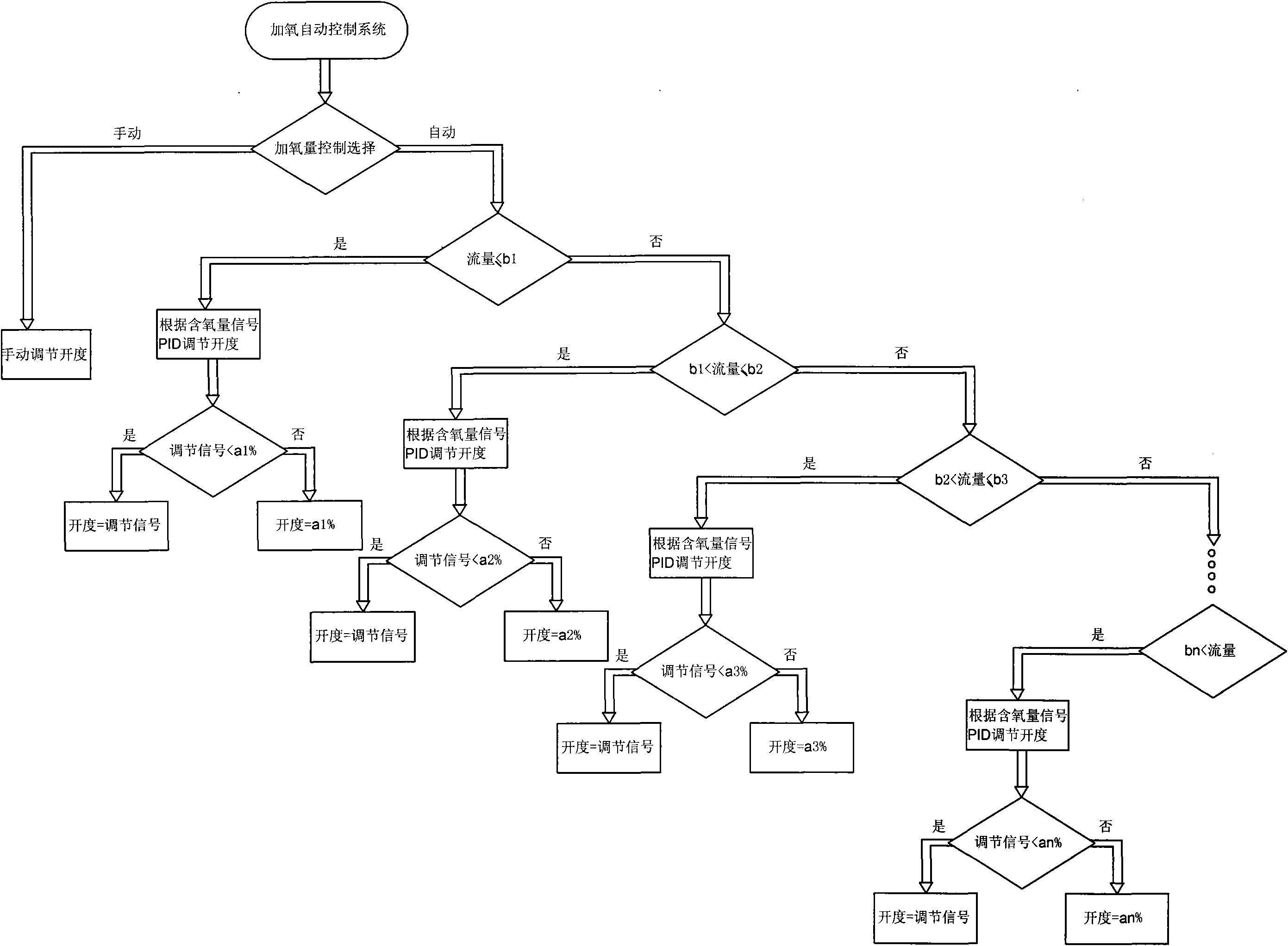

[0022] Since the water quality of the power plant is relatively stable, the flow signal will change with the capacity of the unit, and the flow signal is a real-time signal without lag. Therefore, the present invention introduces feed water and condensed water flow signals to participate in the control on the basis of controlling the oxygen addition rate based on the oxygen content. During specific implementation, it is only necessary to input the water flow detection signal to the PLC or other controllers of the original system, and there is no need to change the original pipeline and electronic control system hardware. When writing the control program, the flow signal is used as the main signal, and the oxygen content is used as the auxiliary signal to control the oxygen addition rate, and the flow signal is processed in sections, and PID adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com