Sludge conditioner and using method thereof

A kind of sludge conditioning and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problem of little improvement in the dewatering performance of papermaking biochemical sludge, and achieve the effect of improving dryness and increasing filtration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

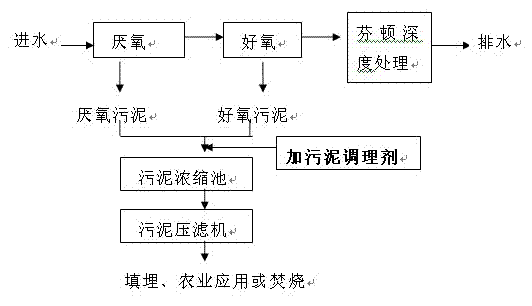

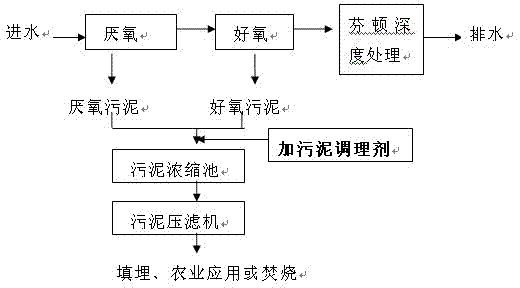

[0016] Weigh a sample of the papermaking biochemical sludge to be conditioned in a 2000ml beaker. The papermaking biochemical sludge is taken from the sludge thickening tank (such as figure 1 (Shown), add a certain amount of sludge conditioner, stir continuously at 30-40℃ for 120-240 minutes, the stirring speed is 50-100 rpm, after precipitation, use laboratory self-made filter press equipment (see Figure 2 ) Extrusion, the pressure is controlled at 5.6Kgf / cm 2 , The filter press time is 4 minutes, and the water-containing sludge used for each test is 1000g. The experimental results show that the dryness of the sludge without the conditioning agent is 20-30% after pressure filtration, and the dryness of the sludge after the conditioning agent is 45-50%.

Embodiment 2

[0018] After the papermaking sludge is digested aerobic or anaerobic, the sludge conditioner of the present invention is added in a ratio of 1:100 before entering the sludge thickening tank, and the sludge is continuously stirred for 120-240 minutes at 30-40°C. The speed is 50-100 revolutions / min. After sedimentation, it enters the sludge thickening tank, and then presses and filters through the sludge filter press. The pressure is controlled at 5.6Kgf / cm2, and the filter press time is 4 minutes. After the sludge is press filtered, the sludge is filtered The biscuit degree is 45-50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com