Method for rapidly solving sticky sludge bulking problem

A sludge bulking and viscous technology, applied in the field of biochemical sewage treatment, can solve the problems of high economic cost, long recovery period, unstable operation effect, etc., achieve low economic cost, low recurrence rate, and solve the difficulty of sludge settlement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and the application examples in the sequence batch system.

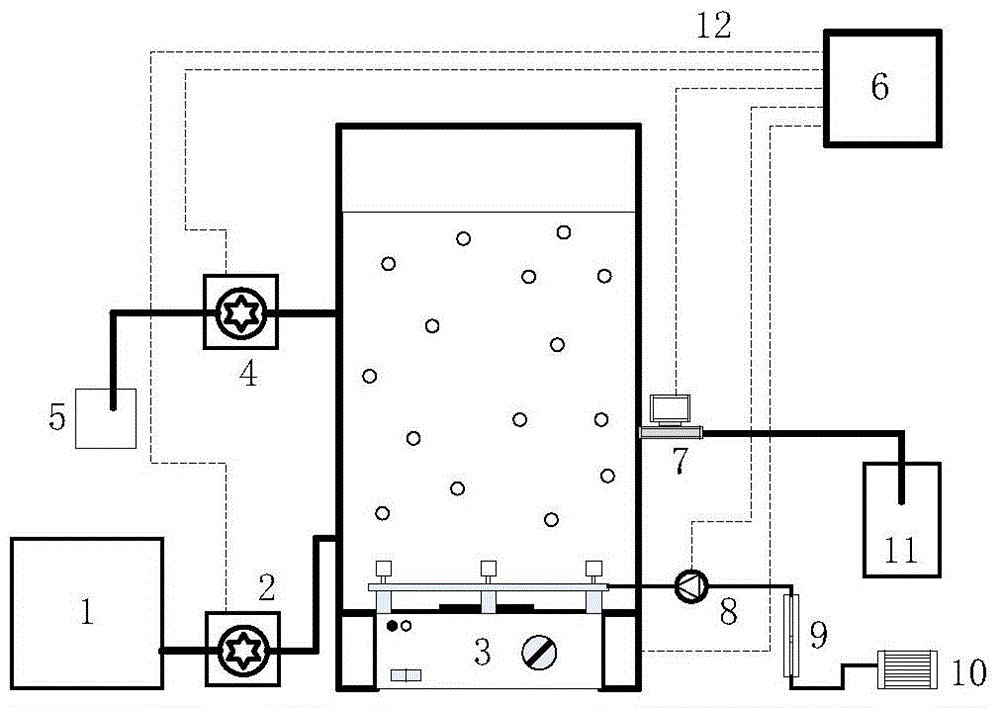

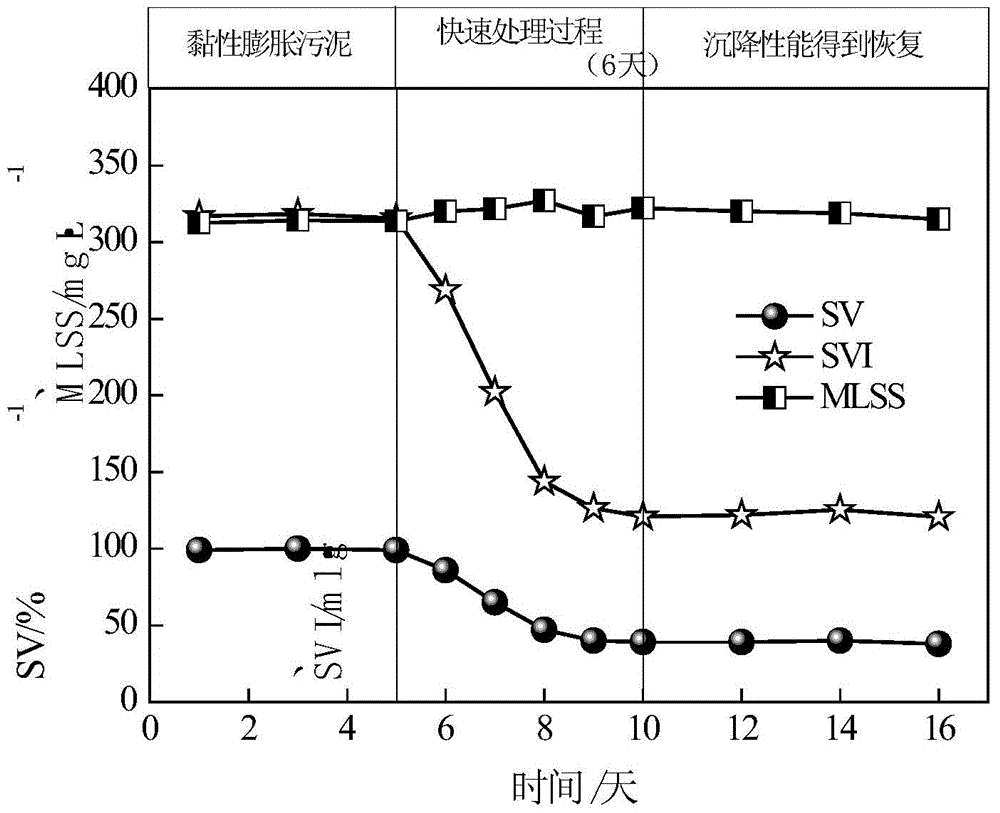

[0021] like figure 1 Shown is a schematic diagram of the sequence batch device. The effective volume of the reactor is 12L, the height is 50cm, and the diameter is 17.5cm. Open and close to realize the automatic operation of the reactor. It runs 4 cycles per day, 6 hours per cycle. One cycle of the sequencing batch reactor consists of 10 minutes of anoxic stirring water intake, 170 minutes of aerobic aeration, 150 minutes of precipitation, 30 minutes of drainage and idle. The drainage ratio per cycle is 50%, the hydraulic retention time is 12 hours, and the sludge age is 20 days. The influent water is artificially distributed. The COD concentration in the influent water is 1000mg / L, the ammonia nitrogen concentration is 30mg / L, and the inorganic phosphorus concentration is 6mg / L. The distribution water also con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com