Process for facilitating sludge decrement

A sludge reduction and activity promotion technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., to reduce pressure, improve expansion characteristics, and improve operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

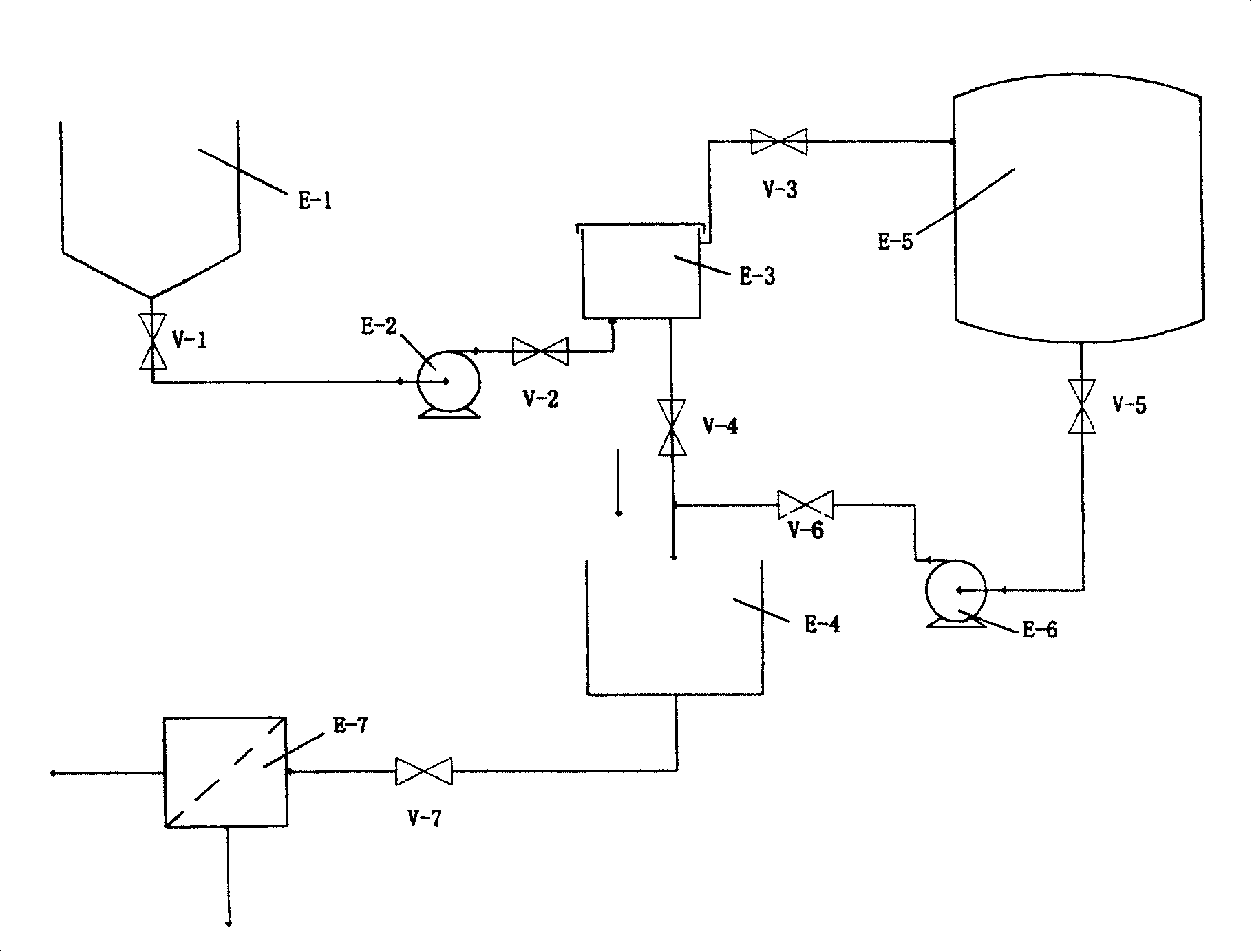

Image

Examples

Embodiment Construction

[0020] 1. Use this technology to treat the remaining sludge of the Yangzi Petrochemical Water Plant, at room temperature, ultrasonic frequency 10kHz, sludge retention time 15min, sound intensity 1000W / m 2 . The moisture content of the sludge is reduced from the original >99% to 81%, and the specific resistance of the sludge is reduced from 3.59×10 12 Down to 0.43×10 12 , The amount of flocculant decreased from 0.7% (dry basis) to 0.6% (dry basis), and the sludge anaerobic digestion time was changed from 22 days to 18 days.

[0021] 2. Using 18kHz ultrasonic (>2000W / m 2 ) Treating surplus sludge from a petrochemical plant can destroy the sludge floc structure, break up the sludge cells, release organic matter into the liquid phase and become soluble organic matter, and increase the sludge SCOD concentration by more than 10 times. For the sludge treated by ultrasonic, the SCOD / TCOD ratio during the digestion process (TCOD is the initial total COD value of the original sludge) is alw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com