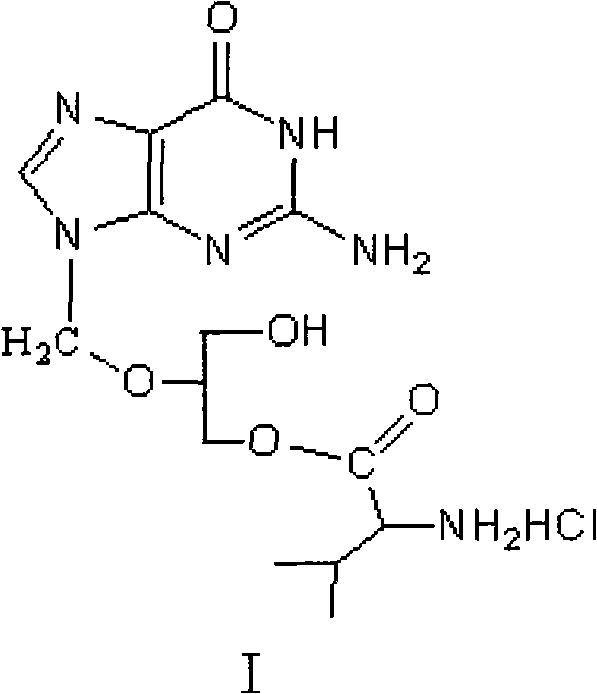

A kind of preparation method of valganciclovir hydrochloride

A technology of valganciclovir hydrochloride and ganciclovir, which is applied in the field of medicine, can solve the problems of difficult separation of monoester and diester, unfavorable industrial production, and high price of orthoester, so as to reduce the difficulty of post-processing, The effect of less impurities and easy purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

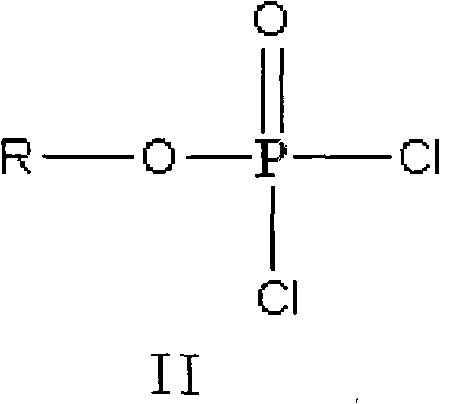

[0025] Preparation of tert-butoxyphosphoryl dichloride

[0026] Add 30.7g of phosphorus oxychloride and 30ml of dichloromethane into a 100ml reaction flask, cool to below 0°C, add 22.2g of tert-butanol dropwise, and then naturally warm to room temperature to react for 3 hours. First, the solvent is evaporated under reduced pressure, and then 36.4 g of tert-butoxyphosphoryl dichloride was distilled out under reduced pressure with an oil pump, with a yield of 95.1%.

Embodiment 2

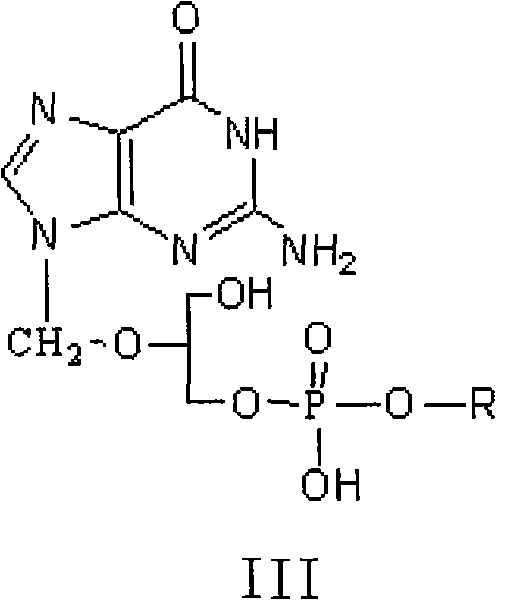

[0028] Synthesis of Ganciclovir Phosphate Monoester Ⅲ

[0029] Add 40.0g tert-butoxyphosphoryl dichloride and 400ml dichloromethane of Example 1 into a 1000ml reaction flask, cool to below 0°C, under the protection of nitrogen, add 76.3g ganciclovir, and then add 12ml triethylamine , And then heated at 20-50 ℃ for 5 hours. The reaction was poured into ice water, the organic layer was separated, the aqueous layer was extracted once more with 200 ml of dichloromethane, the organic layers were combined, washed with water, the organic layer was dried with anhydrous sodium sulfate, filtered, and the solvent was evaporated under reduced pressure. After drying in vacuum, 73.86 g of ganciclovir monoester III was obtained with a yield of 96.8%.

Embodiment 3

[0031] Synthesis of Ganciclovir Diacetate Ⅳ

[0032] Add 49g of ganciclovir monoester and 392mL of DMF of Example 2 into a 1000ml reaction flask, stir and cool to 0~5℃, add 53.9g of CBZ-L-Val, 2.1g of DMAP, 51.1g of DCC, and react at room temperature for 6 hours. After that, the temperature was lowered to 0°C and suction filtered, 10mL DMF was soaked, the filtrate was concentrated and dried at 110°C under reduced pressure to a white solid, then 490mL of methanol was added to stir to dissolve, slowly cooled to 10°C and suction filtered, the filter cake was dried at 80°C to obtain ganciclo The crude product of Wei Dixide IV: 74 g, add 1295 mL of ethanol to the crude product, stir and raise the temperature to 75°C to dissolve, slowly lower the temperature to 0°C and suction filtration. The filter cake is dried at 80°C: 96.42g, yield: 88%, purity: 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com