Hyper-branched polycarboxylate high-efficiency water reducing agent and preparation method thereof

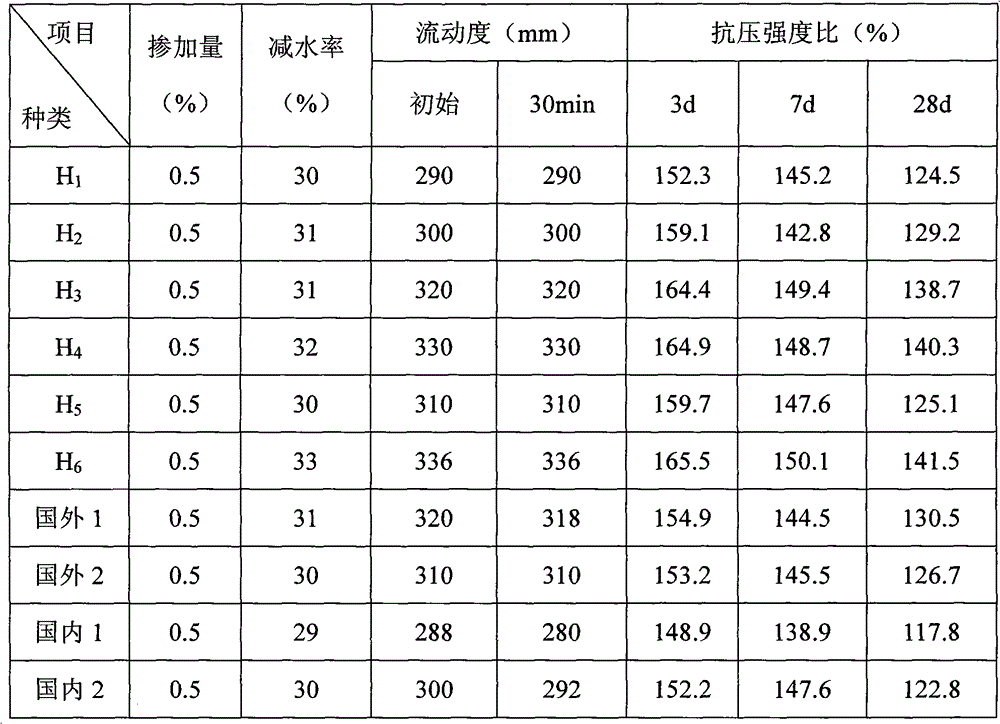

A high-efficiency water reducer and polycarboxylate technology, which is applied in the field of concrete admixtures in chemical building materials, can solve problems such as unstable product performance and poor cement adaptability, and achieve reduced drying shrinkage and small slump loss , Improve the effect of steric hindrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

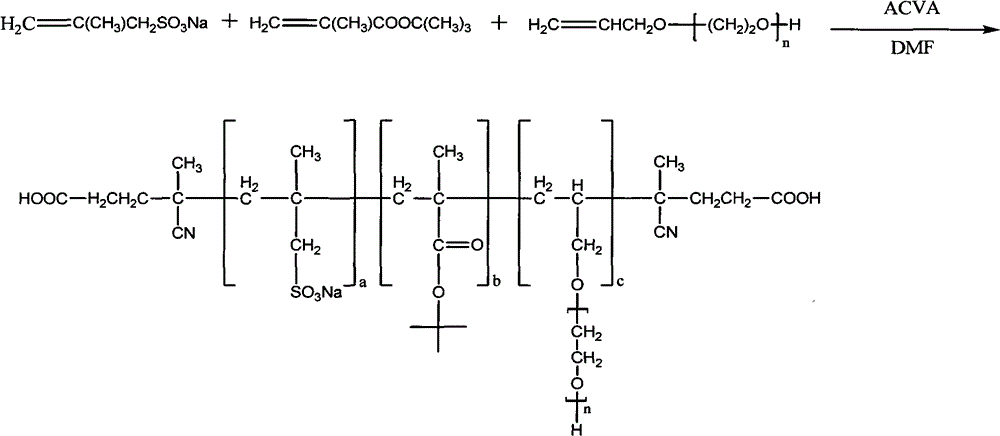

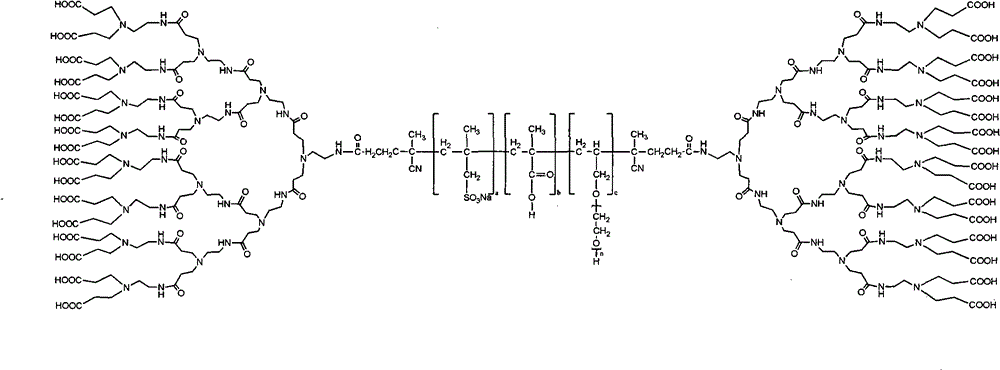

[0028] The hyperbranched polycarboxylate superplasticizer is obtained by polymerizing tert-butyl methacrylate, sodium methacrylate sulfonate and allyl polyoxyethylene ether to obtain the main chain of the comb-shaped copolymer; Under the action of the condensing agent CDI, ethylenediamine and acrylic acid are used as monomers, DMF is used as a solvent, and a condensation reaction is carried out. The branched hyperbranched polyamide is obtained.

[0029] Its preparation method is as follows: 9.48g of sodium methacrylate sulfonate is made into a 3mol / L solution with DMF, and added to a four-necked flask equipped with a stirring device, a spherical condenser, a thermometer and a constant pressure dropping funnel; 30.72g of Tert-butyl methacrylate, 60 g of allyl polyoxyethylene ether-1000 (APEG-1000), and 5.01 g of azodicyanovaleric acid (ACVA) were prepared into a DMF mixed solution, which was added to a constant pressure dropping funnel.

[0030] After passing nitrogen into the...

Embodiment 2

[0032] The hyperbranched polycarboxylate superplasticizer is obtained by polymerizing tert-butyl acrylate, sodium methacrylate sulfonate, and allyl polyoxyethylene ether to obtain the main chain of the comb-shaped copolymer; and then utilizes amidation reaction , under the action of the condensing agent CDI, ethylenediamine and acrylic acid are used as monomers, DMF is used as a solvent, and a condensation reaction is carried out. Polyamide can be obtained.

[0033] Its preparation method is as follows: 9.48g of sodium methacrylate sulfonate is made into a 3mol / L solution with DMF, and added to a four-necked flask equipped with a stirring device, a spherical condenser, a thermometer and a constant pressure dropping funnel; 38.4g Tert-butyl acrylate, 60 g of allyl polyoxyethylene ether-1000 (APEG-1000), and 5.41 g of azodicyanovaleric acid (ACVA) were prepared into a DMF mixed solution, which was added to a constant pressure dropping funnel.

[0034]After passing nitrogen into...

Embodiment 3

[0036] The hyperbranched polycarboxylate superplasticizer is obtained by polymerizing tert-butyl methacrylate, sodium methacrylate sulfonate and allyl polyoxyethylene ether to obtain the main chain of the comb-shaped copolymer; Under the action of the condensing agent CDI, ethylenediamine and methacrylic acid are used as monomers, and DMF is used as a solvent to carry out a condensation reaction. It can be obtained by grafting hyperbranched polyamide.

[0037] Its preparation method is as follows: 9.48g of sodium methacrylate sulfonate is made into a 3mol / L solution with DMF, and added to a four-necked flask equipped with a stirring device, a spherical condenser, a thermometer and a constant pressure dropping funnel; 30.72g of Tert-butyl methacrylate, 90 g of allyl polyoxyethylene ether-1000 (APEG-1000), and 8.49 g of azodicyanovaleric acid (ACVA) were prepared into a DMF mixed solution, which was added to a constant pressure dropping funnel.

[0038] After passing nitrogen i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com