Efficient concrete additive and preparation method thereof

A concrete and additive technology, applied in the field of concrete additives, can solve the problem of low grafting rate of maleic anhydride grafted beta-cyclodextrin macromonomer, poor adaptability of fly ash, stone powder and clay materials, storage and transportation The process is easy to grow mold and other problems, so as to achieve the effect of low preparation cost, high popularization and application value, and good slump retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

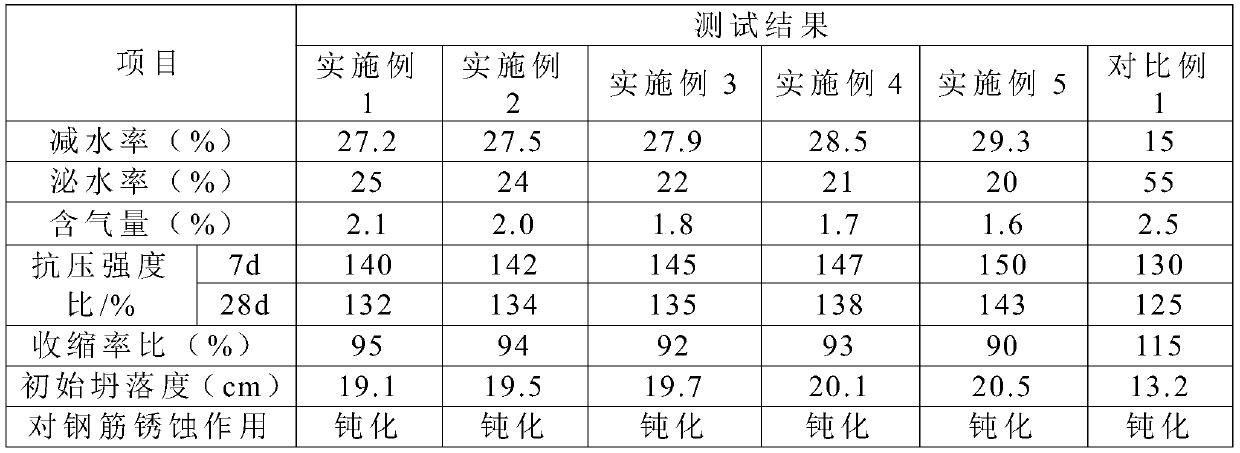

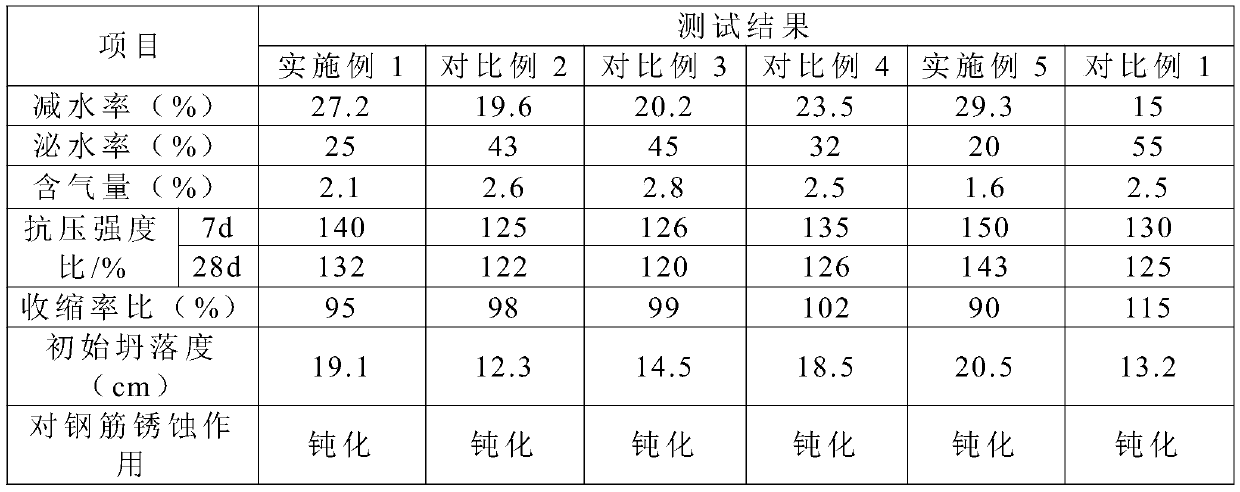

Examples

Embodiment 1

[0029] A preparation method for concrete high-efficiency additives, comprising the steps of:

[0030] Ⅰ Preparation of chlorinated polyethylene glycol monomethyl ether: under the protection of nitrogen atmosphere, add 20 g of anhydrous pyridine, 42.4 g of polyethylene glycol monomethyl ether and 100 g of anhydrous toluene to a three-necked flask in sequence, and heat up to 35 °C Slowly add 10 g of thionyl chloride dropwise to the three-necked flask, finish dropping within 2 hours, and react at constant temperature for 3 hours; stand for stratification, filter the upper layer solution, spin evaporate, filter after cooling, and distill off the solvent to obtain chlorinated Polyethylene glycol monomethyl ether;

[0031] II Preparation of ionized naphthalenesulfonic acid compounds: 26.8g of chlorinated polyethylene glycol monomethyl ether and 10g of 7,7'-iminobis(4-hydroxy-2-naphthalenesulfonic acid) prepared through step I Add it to 120 g of acetone, stir and react at 40°C for 6...

Embodiment 2

[0036] A preparation method for concrete high-efficiency additives, comprising the steps of:

[0037] Ⅰ Preparation of chlorinated polyethylene glycol monomethyl ether: under the protection of a helium atmosphere, add 20 g of anhydrous pyridine, 42.4 g of polyethylene glycol monomethyl ether and 110 g of anhydrous toluene to a three-necked flask successively, and raise the temperature to 37°C Then slowly add 10 g of thionyl chloride dropwise to the three-necked flask, finish dropping within 2 hours, and react at a constant temperature for 3.5 hours; stand for stratification, filter the upper layer solution, spin evaporate, filter after cooling, and distill off the solvent to obtain chlorine Polyethylene glycol monomethyl ether;

[0038] II Preparation of ionized naphthalenesulfonic acid compounds: 26.8g of chlorinated polyethylene glycol monomethyl ether and 10g of 7,7'-iminobis(4-hydroxy-2-naphthalenesulfonic acid) prepared through step I Add it to 130 g of acetone, stir and...

Embodiment 3

[0043] A preparation method for concrete high-efficiency additives, comprising the steps of:

[0044] Ⅰ Preparation of chlorinated polyethylene glycol monomethyl ether: under the protection of a neon atmosphere, add 20 g of anhydrous pyridine, 42.4 g of polyethylene glycol monomethyl ether and 135 g of anhydrous toluene to a three-necked flask successively, and heat up to 40 °C Then slowly add 10 g of thionyl chloride dropwise to the three-necked flask, finish dropping within 2 hours, and react at a constant temperature for 4 hours; stand for stratification, filter the upper layer solution, spin evaporate, filter after cooling, and distill off the solvent to obtain chlorine Polyethylene glycol monomethyl ether;

[0045] II Preparation of ionized naphthalenesulfonic acid compounds: 26.8g of chlorinated polyethylene glycol monomethyl ether and 10g of 7,7'-iminobis(4-hydroxy-2-naphthalenesulfonic acid) prepared through step I Add it to 145 g of acetone, stir and react at 50°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com