Preparation method for high-efficiency heavy calcium carbonate grinding dispersing agent with comb-shaped structure, product and application of product

A dispersant and high-efficiency technology, applied in the treatment of dyeing polymer organic compounds, dyeing physical treatment, fibrous fillers, etc., can solve the problems of precipitation and the reduction of dispersant utilization efficiency, and achieve excellent performance, accurate and controllable molecular weight, reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

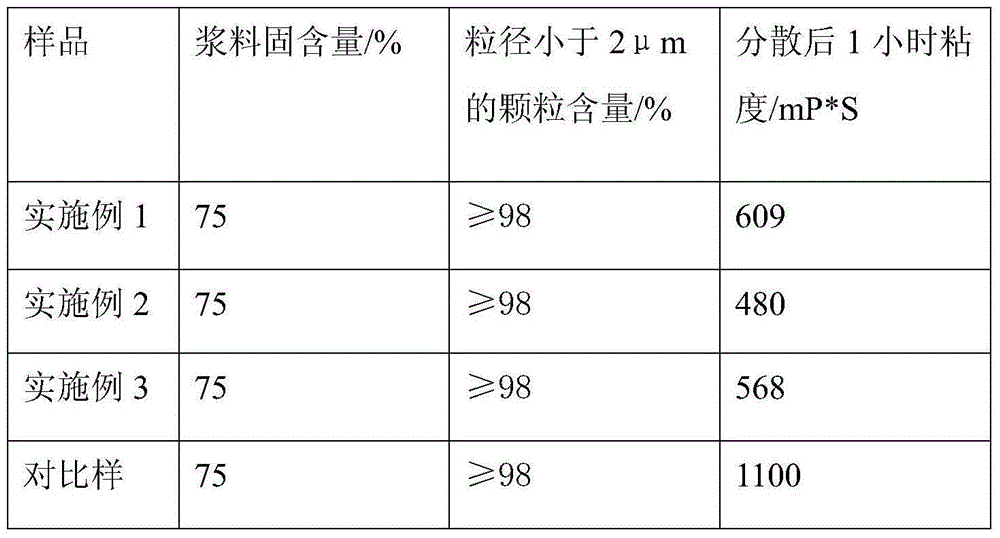

Examples

preparation example Construction

[0033] The first aspect of the present invention provides a kind of preparation method of the efficient heavy calcium grinding dispersant of comb structure, comprises the steps:

[0034] (1) Add vinyl carboxylic acid monomer, methacrylic acid polyethylene glycol monomer, polythioester chain transfer agent, initiator in the solvent, and use nitrogen gas bubbling for a certain period of time, then seal;

[0035] (2) heating to a certain temperature for a period of time;

[0036] (3) After the reaction finishes, the solvent is distilled off and diluted with water;

[0037] (4) Add one or more alkaline reagent solutions to adjust the pH of the system to 5-8, and add water to adjust the solid content to 20%-50%, so as to obtain a high-efficiency heavy calcium grinding dispersant.

[0038] In a preferred embodiment, the mass parts of each reactant are as follows:

[0039] Vinyl carboxylic acid monomer 30-100 parts

[0040] Polyethylene glycol methacrylate monomer 2-30 parts

[0...

Embodiment 1

[0055] The preparation of the poly(acrylic acid-co-ethylene glycol methacrylate) salt of low molecular weight narrow distribution of embodiment 1

[0056] In the reaction vessel, add 8.98 g of dithioester chain transfer agent 4-cyano-4-dithiobenzoyloxyvaleric acid, 1.90 g of initiator azobisisobutyronitrile, and 320.0 g of solvent dioxane And monomer acrylic acid 172g, methacrylate ethylene glycol ester 118g. The system was sealed after bubbling with nitrogen for 20 minutes, and then heated to 70° C. for 12 hours to react. After the reaction is over, the resulting solution is distilled off under reduced pressure to remove the solvent, then diluted with a small amount of water, then add the mixed suspension of alkali reagent with a molar ratio of [calcium hydroxide]:[magnesium hydroxide]=2:1 to adjust the pH to 6.89, and add water Adjust the solid content of the polymer solution to 25% to obtain the final dispersant sample. The obtained dispersant has a weight average molecular...

Embodiment 2

[0057] The preparation of the polymethacrylate of embodiment 2 low molecular weight narrow distribution

[0058] Add 9.12g of dithioester chain transfer agent cyanoisopropyl dithiobenzoate, 2.22g of initiator azobisisobutyronitrile, 240.21g of solvent tetrahydrofuran and 122.00g of monomer methacrylic acid into the quartz reaction vessel, Ethylene glycol methacrylate 35.63g. The system was sealed after bubbling with nitrogen for 20 minutes, and then heated to 80° C. for 8 hours to react. After the reaction is over, the resulting solution is distilled off under reduced pressure to remove the solvent, then diluted with a small amount of water, then add the mixed suspension of alkali reagent with a molar ratio of [calcium hydroxide]:[magnesium hydroxide]=1:1 to adjust the pH to 7.11, and add water Adjust the solid content of the polymer solution to 25% to obtain the final dispersant sample. The weight-average molecular weight of the obtained dispersant was 7830, and the molecul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com