Method for preparing high-temperature resistant and salt resistant shear strength-improving agent for drilling fluid

A high temperature resistance and drilling fluid technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of rare on-site successful application examples, less research on cutting agents, and stagnation of research work, etc., to achieve good results Environmental protection effect, low cost, low plastic viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

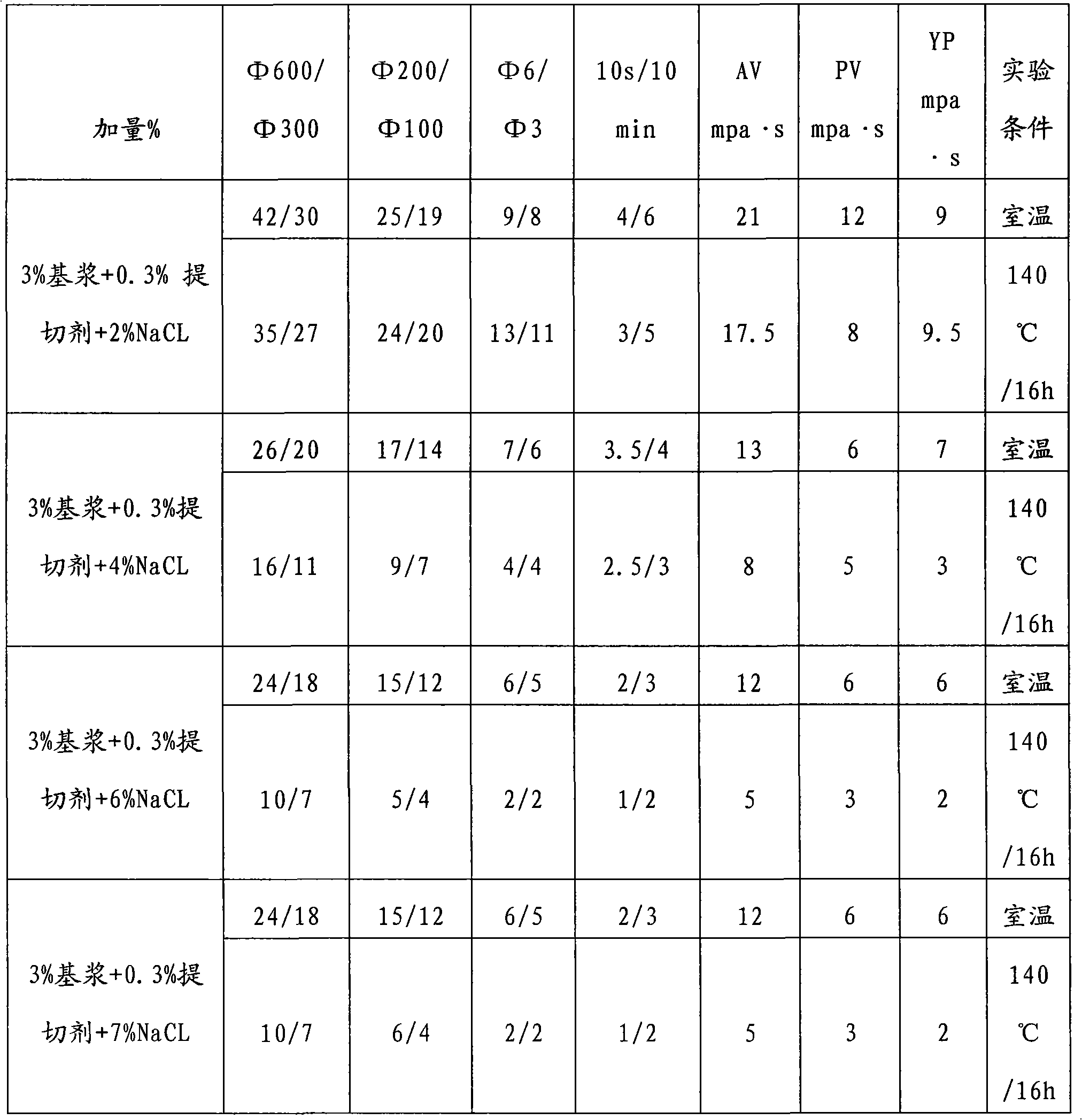

Examples

Embodiment Construction

[0006] (1) Preparation of anti-high temperature and anti-salt anti-shearing agent for drilling fluid:

[0007] The preparation method of the anti-high temperature and anti-salt anti-shearing agent for drilling fluid in this embodiment comprises the following steps:

[0008] (1) Raw material preparation: alkali metal, water, starch, organic sodium salt and reduction initiator, calculated with the addition amount of every 100 milliliters of water: alkali metal 18.8 grams, starch 24.7 grams, organic sodium salt 13.3 grams, reduction initiator 0.15 gram;

[0009] (2) Mother liquor preparation: according to the raw material ratio of step (1), alkali metal and water are reacted, and starch is added after completion of the reaction;

[0010] (3) Chelate copolymerization: add organic sodium salt to the mixture obtained in step (2) under stirring, then heat to 80°C, and react for 1h;

[0011] (4) Adding auxiliary materials: adding a reduction initiator to the mixture obtained in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com