High-precision temperature measuring device and method

A temperature measurement, high-precision technology, used in measurement devices, heat measurement, thermometers, etc., can solve the problems of increasing the input voltage offset and input noise, increasing the circuit cost and circuit area, and difficult to control the measurement accuracy. High precision, good multi-channel consistency, good stability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

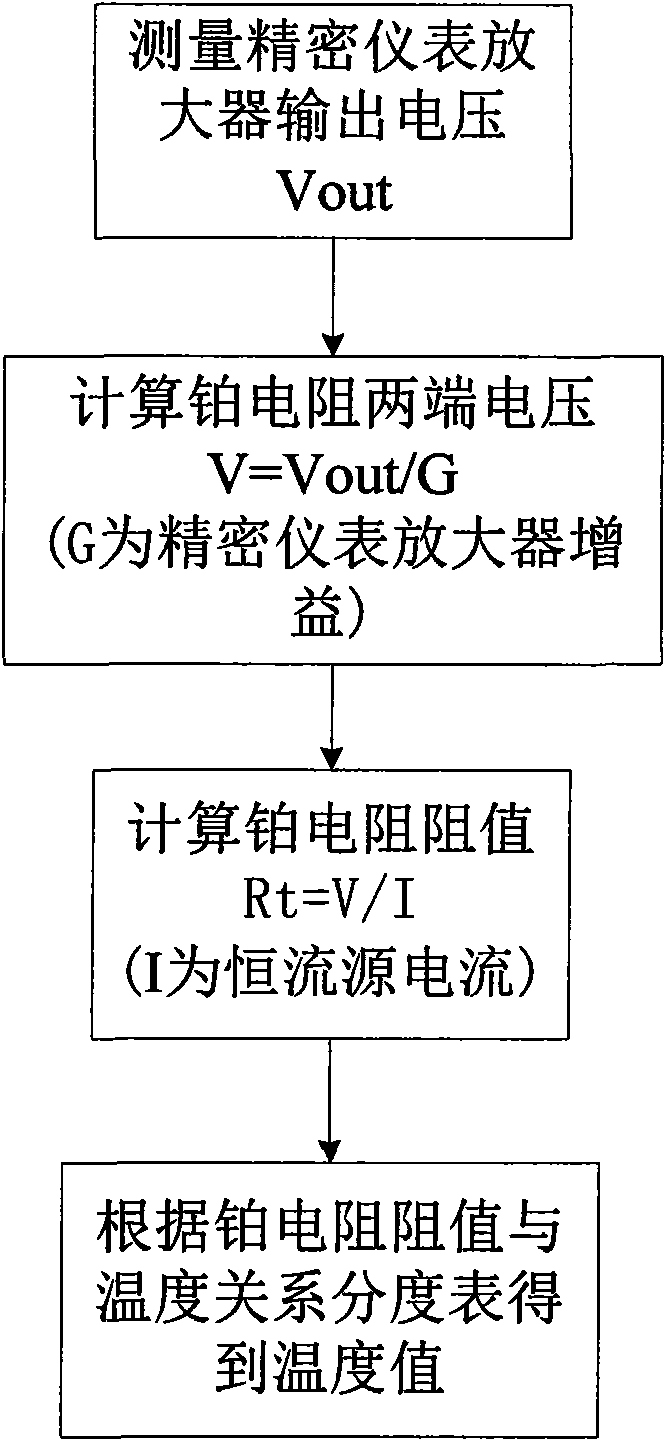

[0021] A high-precision temperature measuring device and its measuring method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

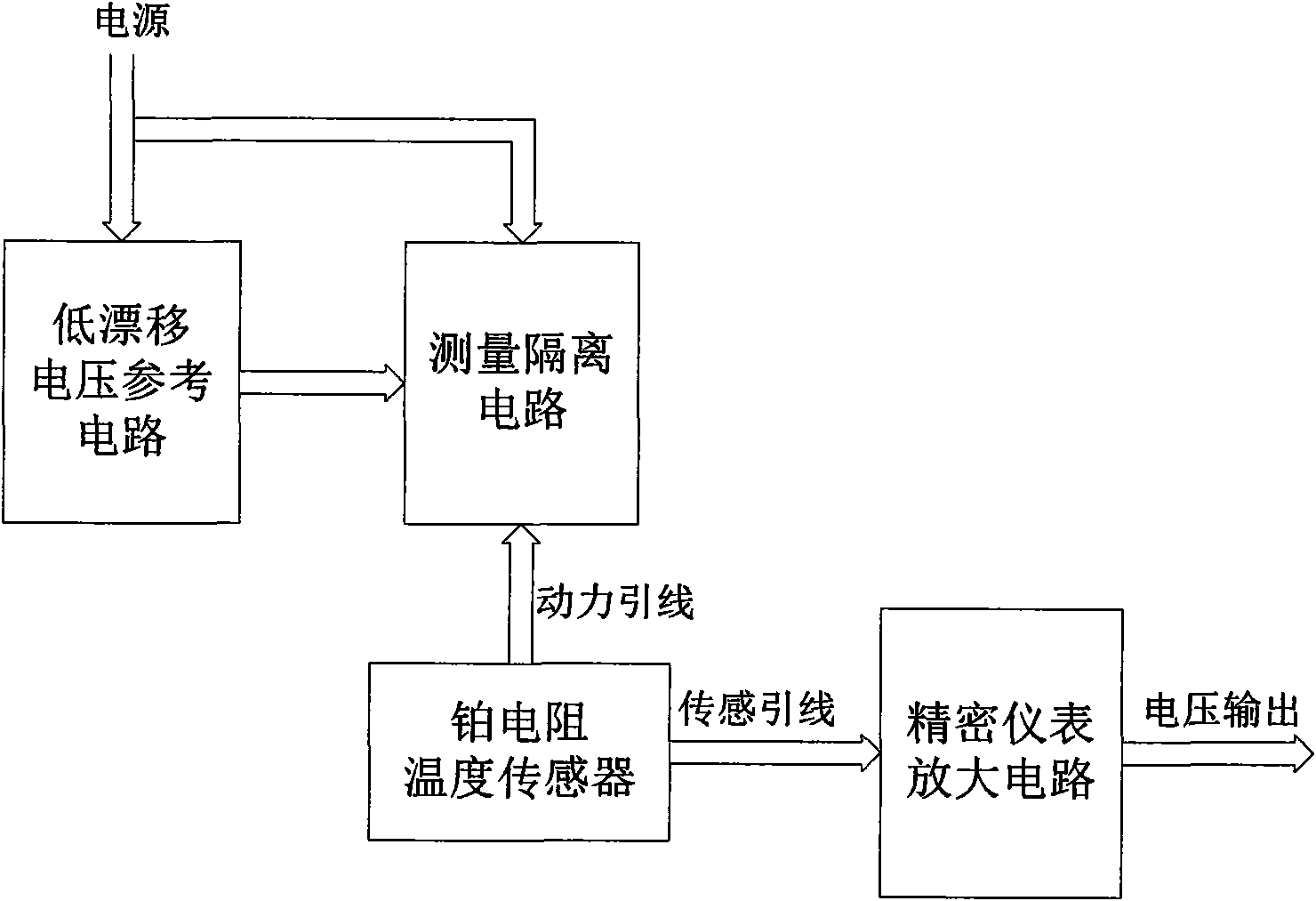

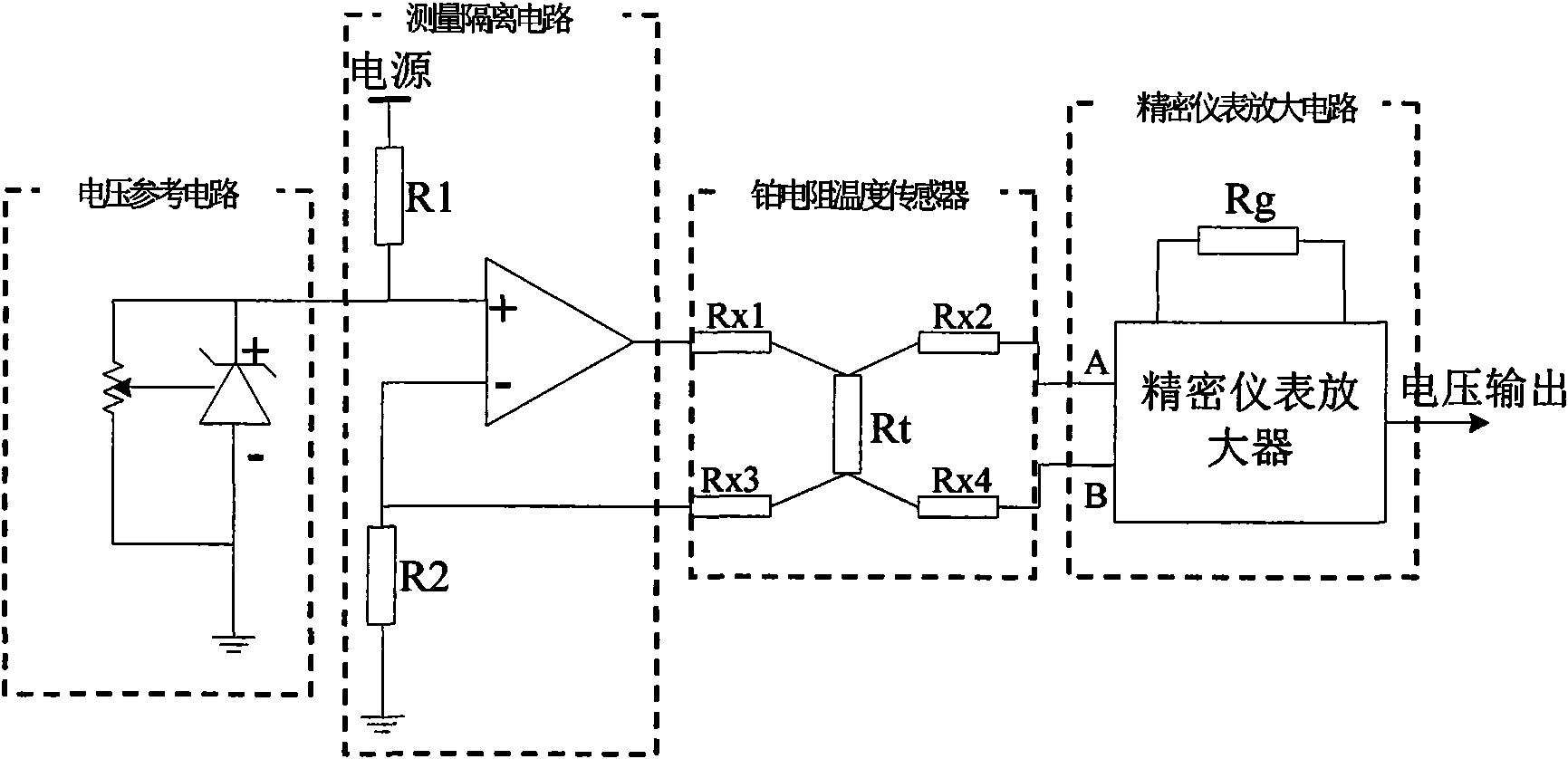

[0022] figure 1 It is a block diagram showing the composition of a high-precision temperature measuring device of the present invention. Such as figure 1 As shown, the high-precision temperature measuring device of the present invention is mainly composed of a low-drift voltage reference circuit part, a measurement isolation circuit part, a platinum resistance temperature sensor and a precision instrument amplifier circuit part.

[0023] The low-drift voltage reference circuit part is composed of a high-precision voltage reference and a fine-tuning sliding rheostat, which provides a low-drift reference voltage for the measurement isolation circuit;

[0024] The measurement isolation circuit part is composed of a high-precision amplifier with high gain and close to zer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com