Rhythm control system of clothing production line

A control system and production line technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problem of each worker's production rhythm being unable to control and guide, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

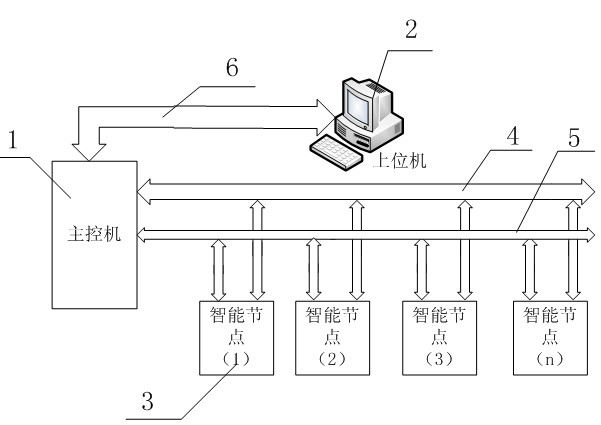

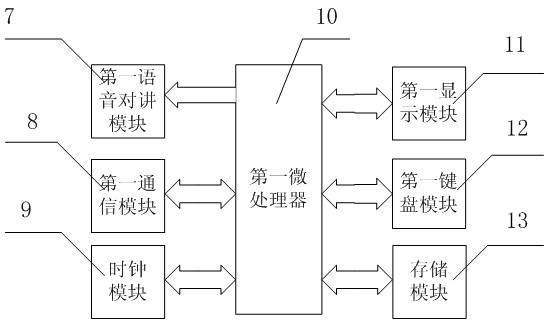

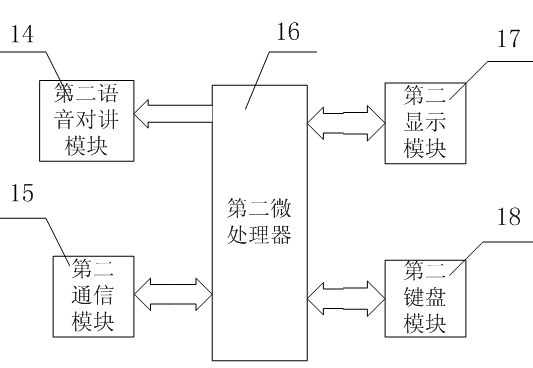

[0021] refer to Figure 1-3 , the garment production line rhythm control system, comprising a host computer 2, a main control computer 1 and an intelligent node 3, the main control computer 1 is connected to the upper computer 2 in communication, and the main control computer 1 is connected to the intelligent node 3 in communication;

[0022] The main control machine 1 sends a production rhythm signal to the intelligent node 3, and the rhythm signal includes the rhythm time and the number of the intelligent node. If the intelligent node 3 completes the work of the station within the rhythm time, it sends a signal of completing the work of the station to the master. Control machine 1, if the intelligent node 3 does not complete the station work within the rhythm time, send an overtime alarm signal to the main control machine 1; the main control machine 1 sends the received production information signals of each station to the upper position machine 2; the upper computer 2 reset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com