X-ray diagnostic apparatus

A diagnostic device and X-ray technology, which is applied in the direction of diagnosis, radiological diagnostic instruments, measuring devices, etc., and can solve the problem of X-ray detection components becoming defective components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0026] (First embodiment: counting of blocks)

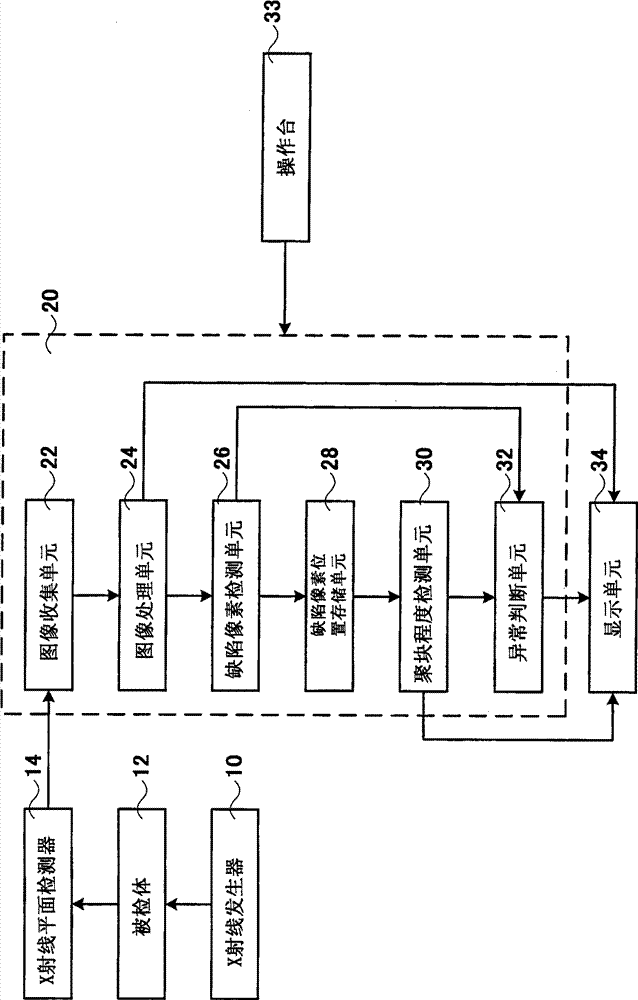

[0027] Hereinafter, the first embodiment will be described with reference to the drawings. figure 1 The overall structure of the X-ray diagnostic apparatus is shown in . The X-ray apparatus in this embodiment includes: an X-ray generator 10 for irradiating X-rays to a subject 12, and an X-ray plane detector for detecting transmitted X-rays of the subject 12, which is disposed opposite to the X-ray generator 12. The detector 14, the signal processing unit 20 for grasping the degree of agglomeration of defective pixels based on the X-ray information obtained from the X-ray plane detector 14, and the display unit 34 for displaying the state of the X-ray plane detector 14.

[0028] The X-ray generator 10 has, for example, an X-ray tube composed of a cathode emitting thermal electrons and an anode receiving electrons to generate X-rays. The X-rays generated by the X-ray generator 10 are irradiated to the subject 12 . The X-ray plan...

no. 2 approach

[0043] (Second embodiment: continuous)

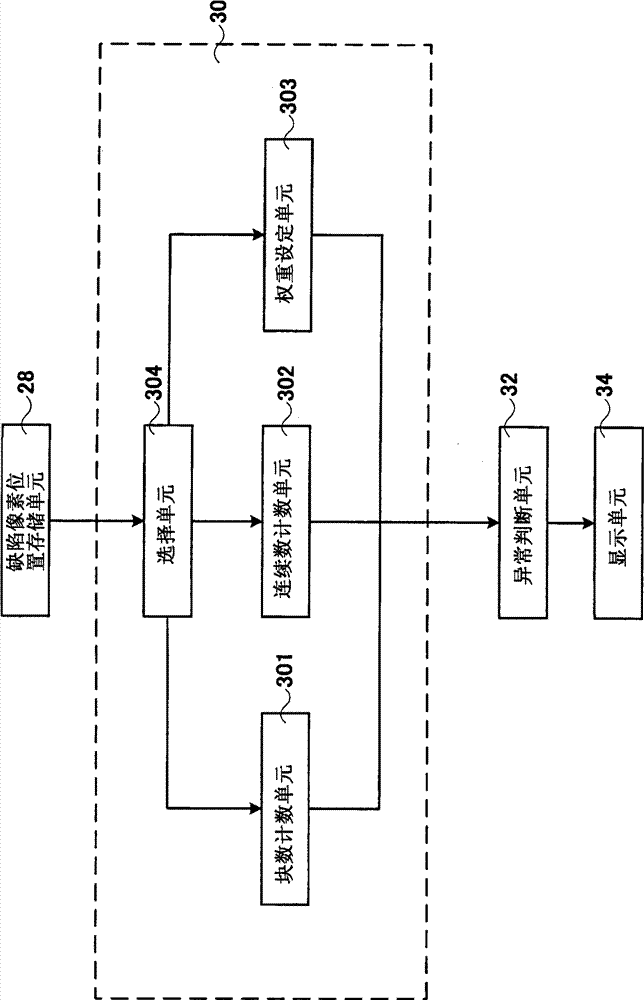

[0044] use Figure 1-6 Describes the second embodiment. The difference from the first embodiment is that whether the X-ray plane detector 14 is abnormal is judged based on the continuous state of defective pixels corresponding to defective elements. The selection unit 304 in this embodiment selects the continuous number counting unit 302 .

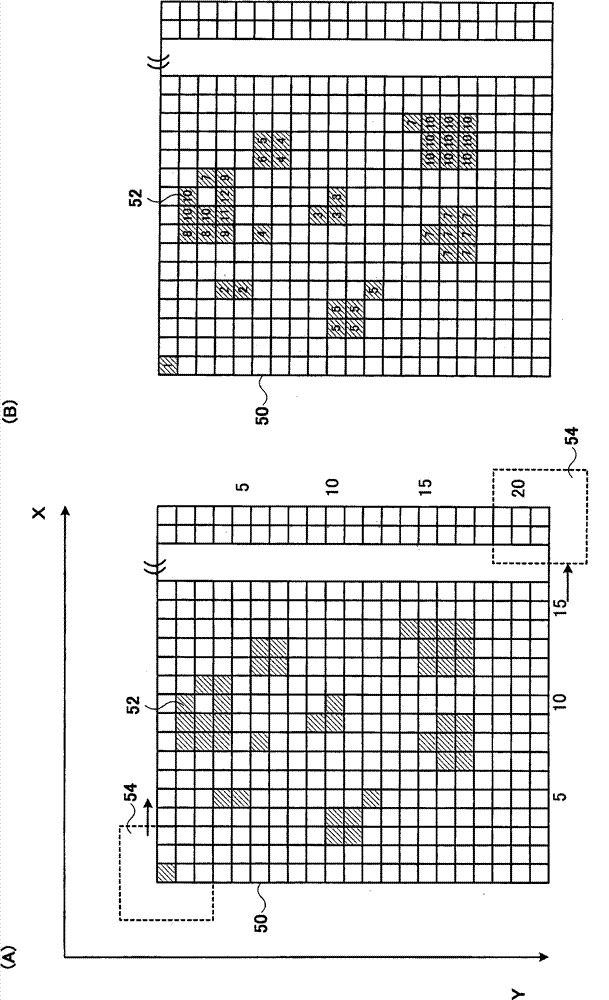

[0045] The continuous number counting unit 302 of the degree of agglomeration detection unit 32 is based on the position of the defective pixel of the X-ray image data 50 stored in the defective pixel position storage unit 28, and counts the positions of the defective pixels adjacent to the upper, lower, left and right Counting is performed continuously to detect the continuous status of defective components.

[0046] For example, for the defective pixel (1, 1), since there is no adjacent defective pixel above, below, left, or right, the consecutive number counting unit 302 counts as the consecut...

no. 3 approach

[0051] (Third embodiment: block count+continuation)

[0052] use Figure 1-6 A third embodiment will be described. The difference from the first embodiment and the second embodiment is that whether the X-ray plane detector 14 is abnormal is judged based on the block number and the continuous number of defective pixels corresponding to the defective element. The selecting section 304 in this embodiment selects the block number counting section 301 and the continuous number counting section 302 .

[0053] As described in the first embodiment, the block number counting unit 301 counts the position information of all defective pixels judged as defective components based on the position information of the X-ray image data 50 stored in the defective pixel position storage unit 28, Defective pixels are counted, and the continuous number counting unit 302 is based on the position of the defective pixel in the X-ray image data 50 stored in the defective pixel position storage unit 28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com