Rubber composition and tire

一种橡胶组合物、橡胶的技术,应用在特殊轮胎、轮胎零部件、运输和包装等方向,能够解决低发热性、劣化补强性、橡胶组合物低发热性等问题,达到低发热性和耐磨耗性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7 and comparative example 1-2

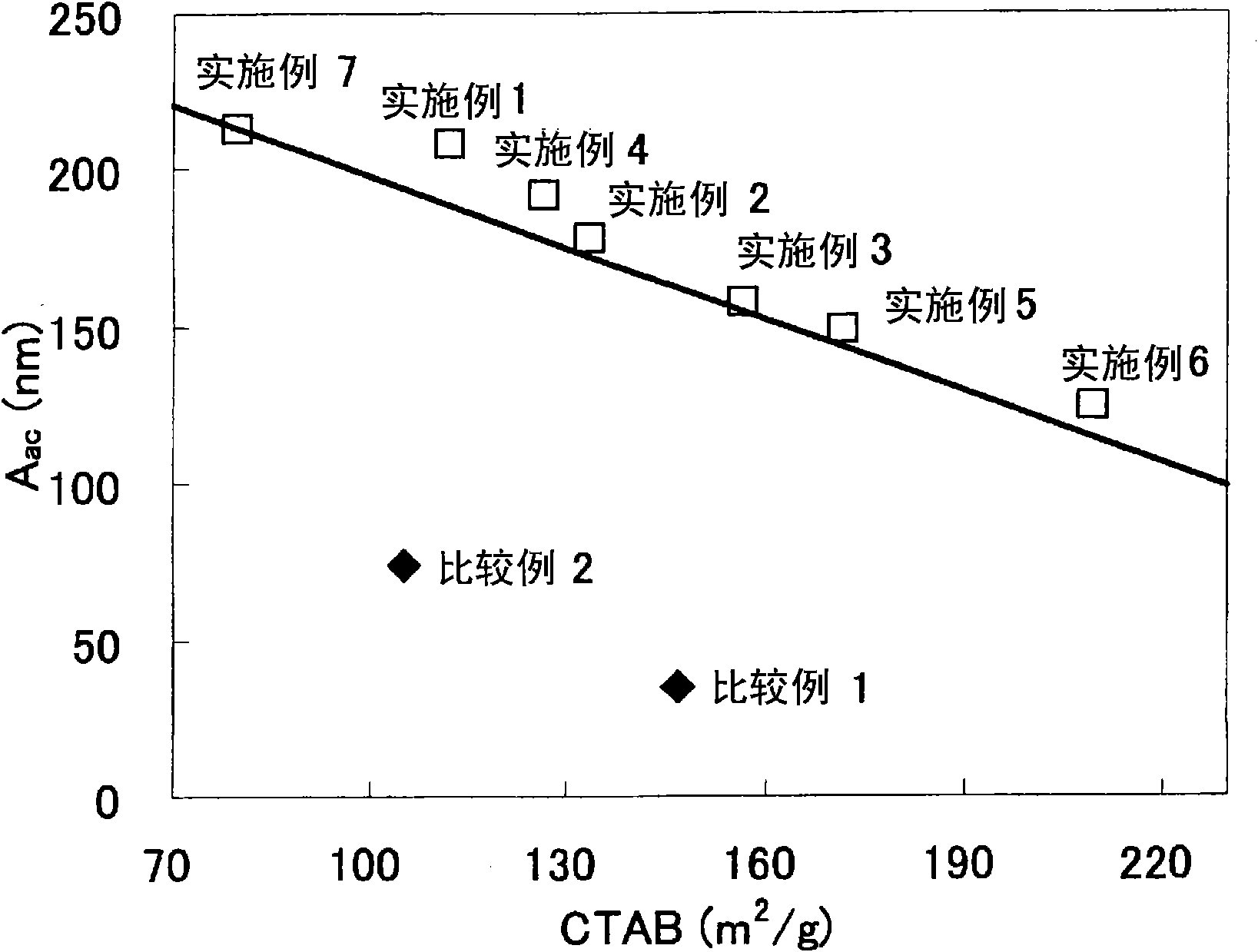

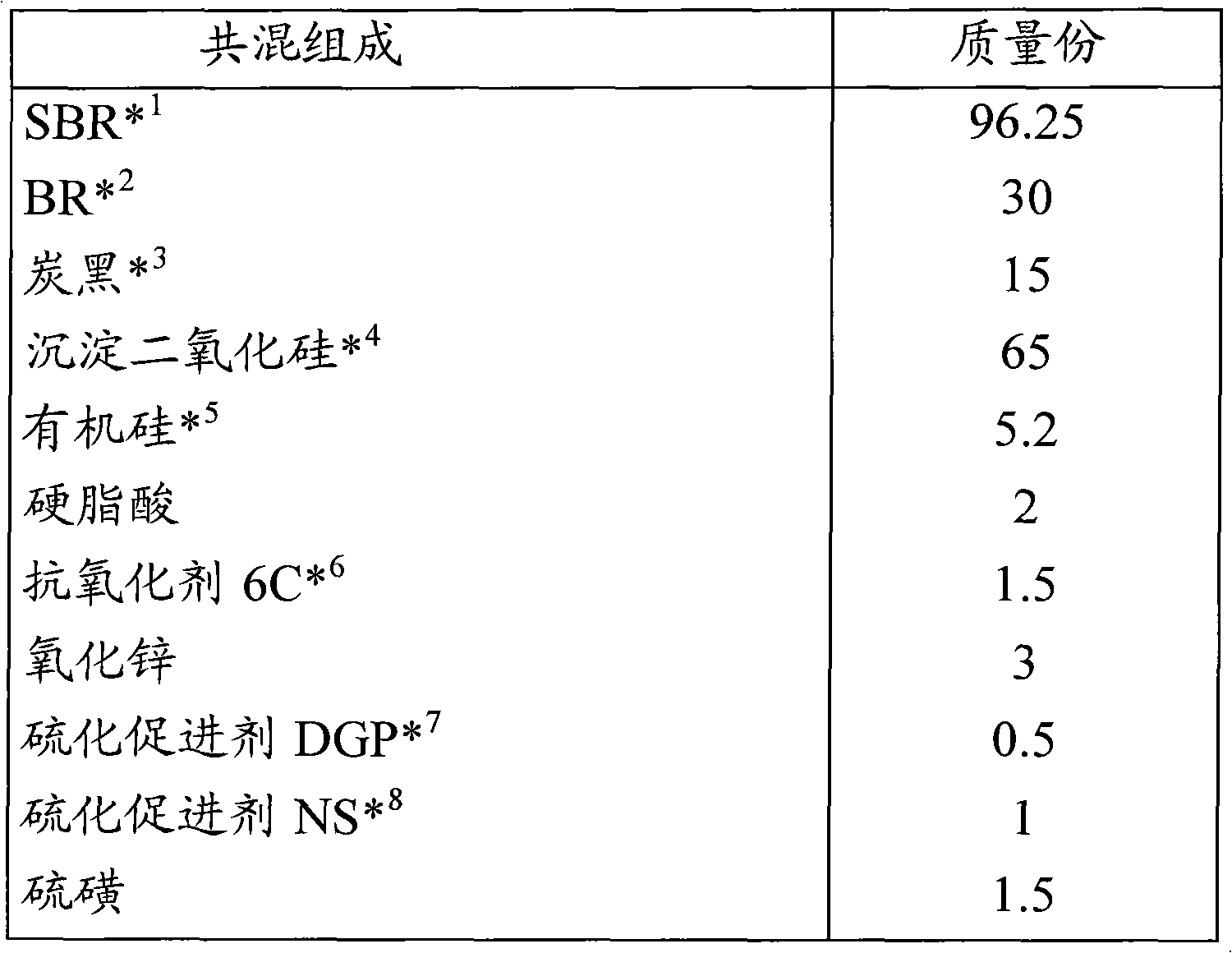

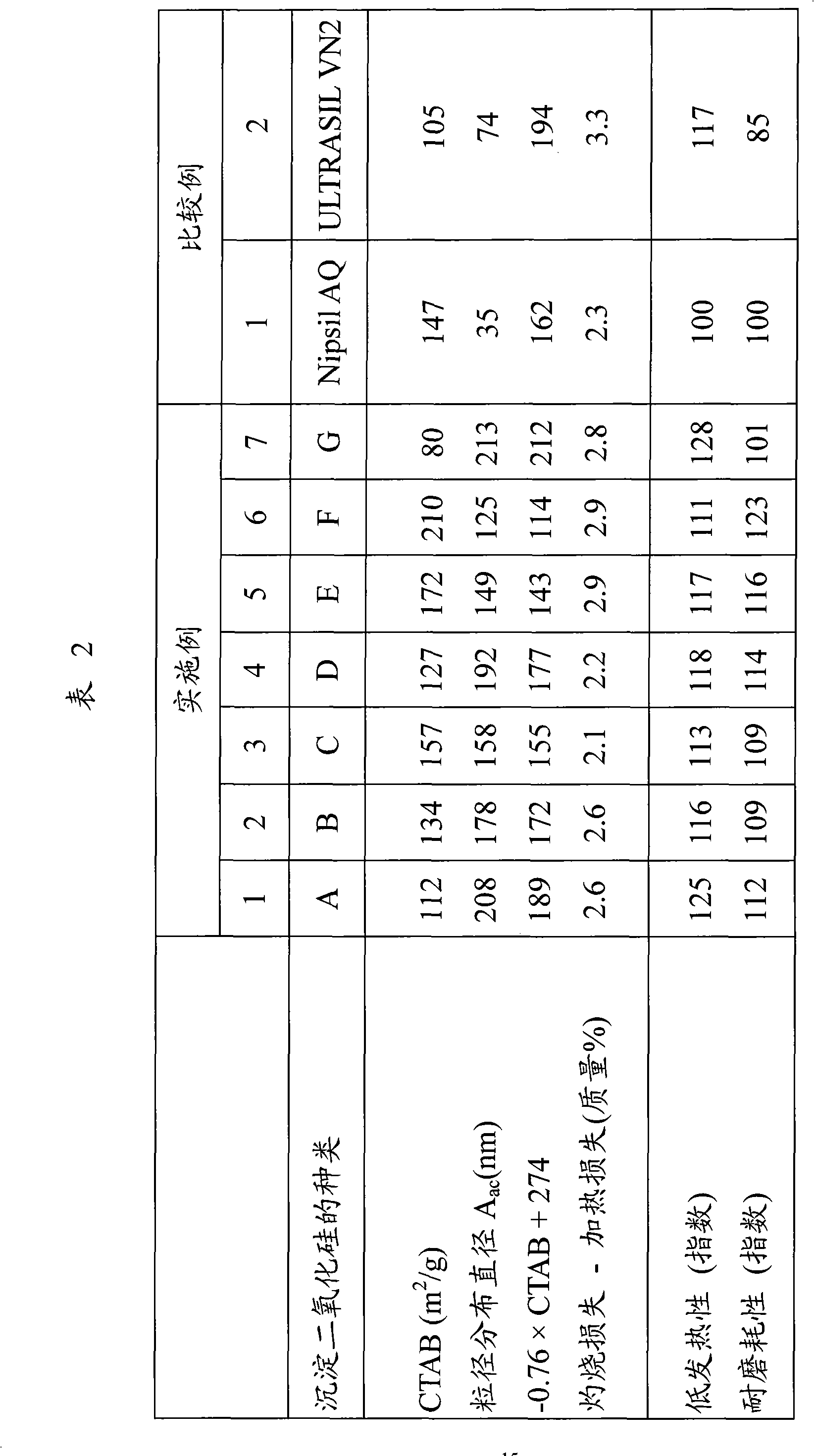

[0099] By using the precipitated silicas A-G prepared respectively in Examples 1-7 of Production Examples A-G, Nipsil AQ manufactured by Tosoh Silica Corporation in Comparative Example 1, and ULTRASILVN2 manufactured by Degussa AG in Comparative Example 2, according to a conventional method Rubber compositions containing various types and amounts of rubber components and compounding ingredients shown in Table 1 were prepared.

[0100] Table 2 shows the physical properties of precipitated silica and vulcanized rubber used in each of Examples and Comparative Examples.

[0101] Table 1

[0102]

[0103] Notes:

[0104] * 1: SBR#120 (manufactured by JSR Corporation); it was oil-extended by 37.5 parts by mass of aromatic oil based on 100 parts by mass of the rubber component

[0105] * 2: BR 150L (manufactured by Ube Industries, Ltd.)

[0106] * 3: Seast KH (N339) (manufactured by Tokai Carbon Co., Ltd.)

[0107] * 4: Recorded in the production examples A-G of precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com