Grain flattening machine

A kind of technology of unwinding machine and grain, which is applied in the field of grain unwinding machinery and semi-automatic unwinding of grain machinery, which can solve the problems of manual operation of grain unwinding, shorten the time of unwinding, improve the efficiency of unwinding, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

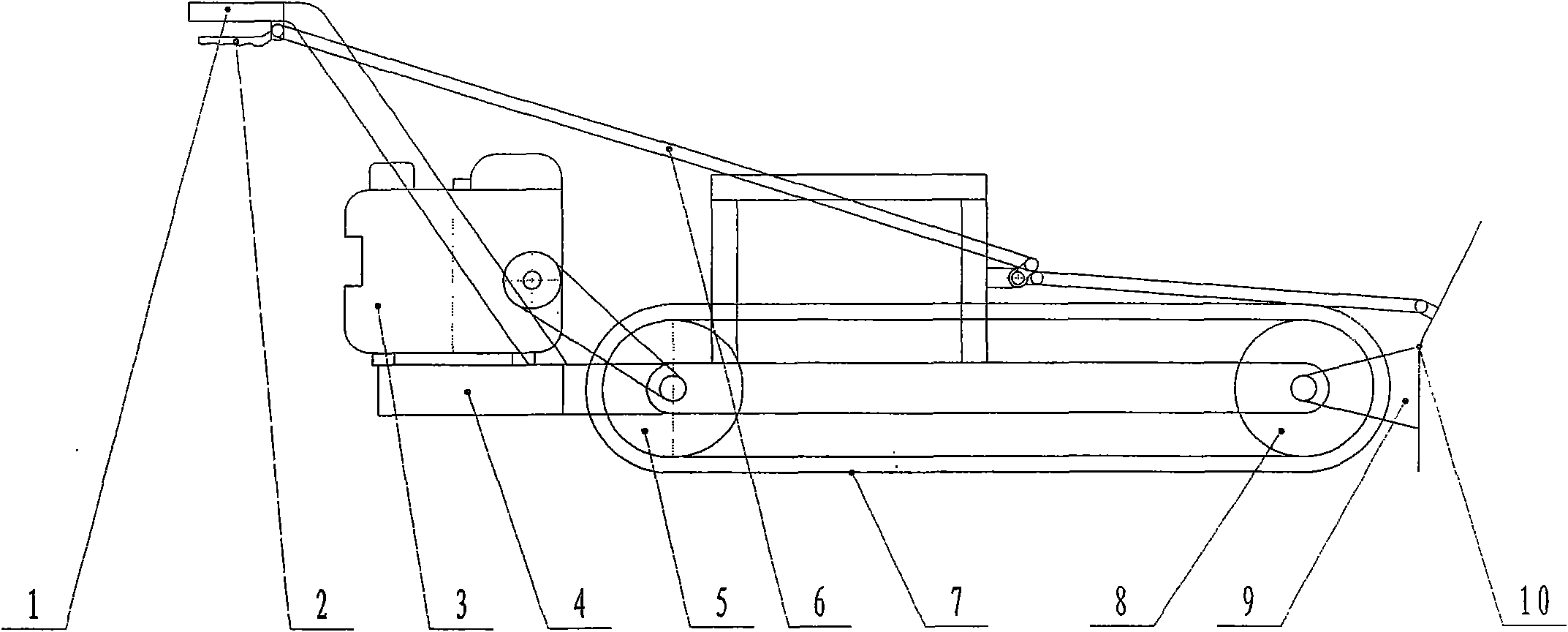

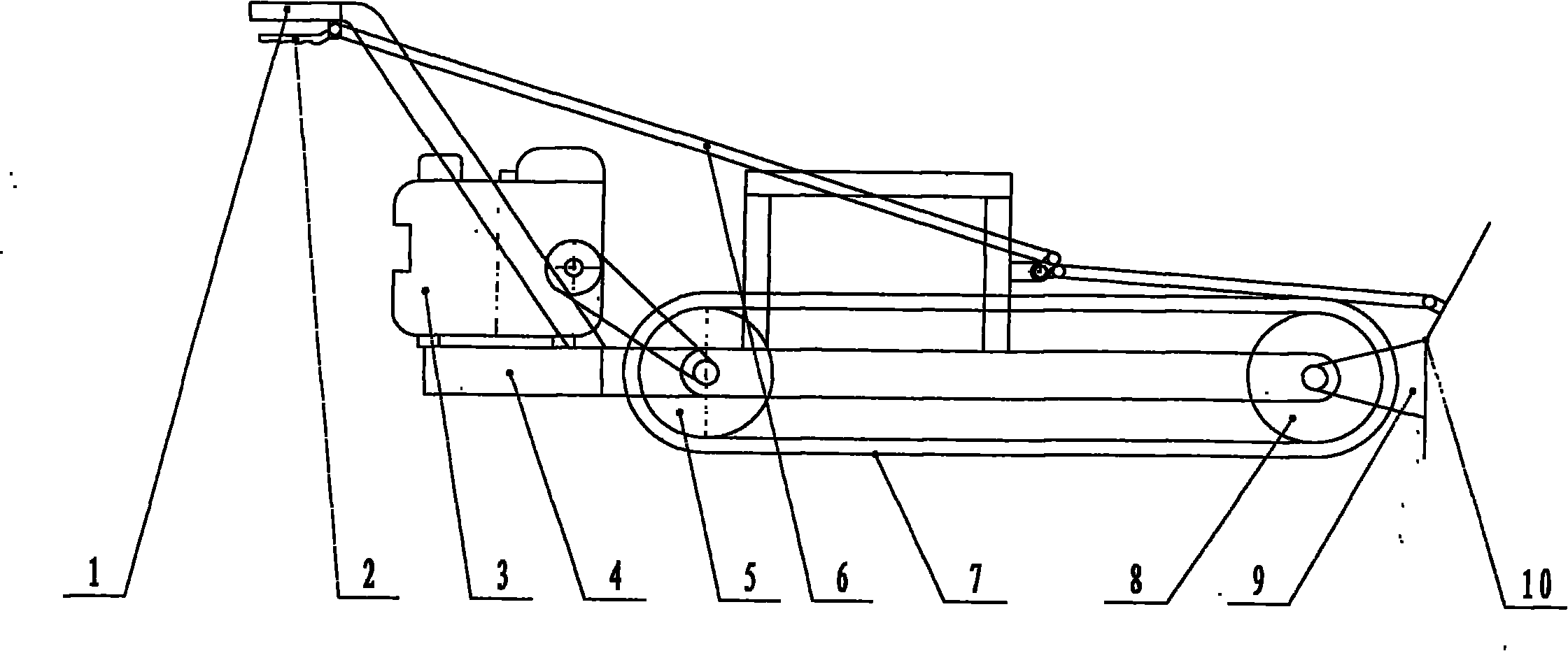

[0012] As shown in the figure, the grain leveling machine is composed of a chassis frame 4, a driving diesel engine 3, and a grain pushing plate 10. It is characterized in that: the driving diesel engine 3 is installed on the chassis frame 4 at the rear end of the whole machine, and Drive wheel 5 is installed at the end, and reversing wheel 8 is equipped with at the front end, and rubber covering belt 7 is housed on the driving wheel and reversing wheel, and grain pushing plate 10 is contained in the front end of complete machine, is supported by grain pushing plate palm 9, The grain pushing plate 10 is connected with the grain pushing plate adjusting hand brake 2 by adjusting the pull rod 6 . The height regulation of pushing grain plate 10 is finished by pushing grain plate adjusting hand brake 2, adjusting pull bar 6 and pushing grain plate support 9. When complete machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com