Special lifting machine for lifting wind power generation equipment

A technology of wind power generation equipment and cranes, which is applied in the direction of cranes, etc., can solve the problems of large number of points in wind farms, lack of large machinery, and harsh hoisting environment, etc., to achieve convenient disassembly and transfer, many hoisting points, and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing, the present invention will be further described:

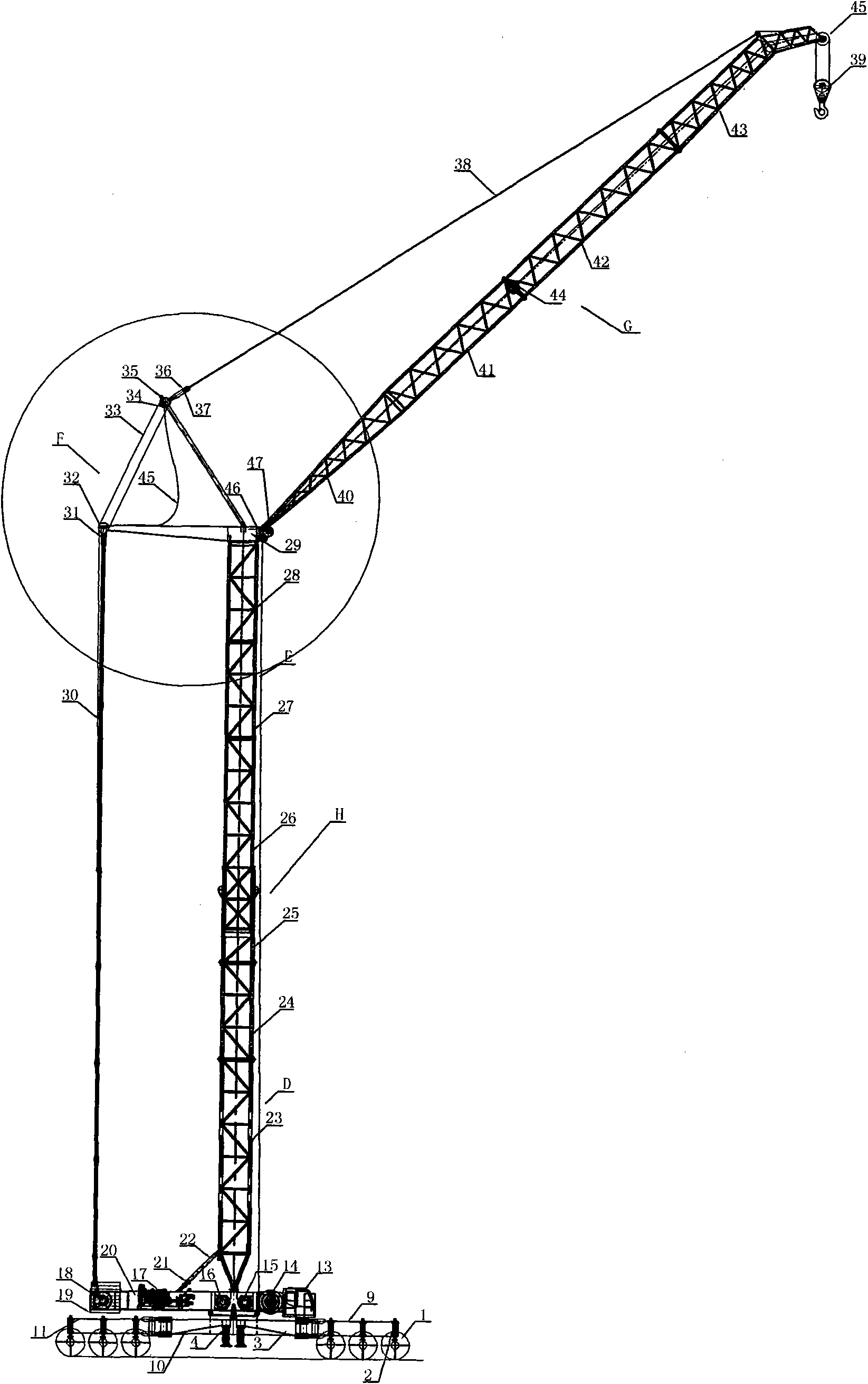

[0051] The special crane for wind power hoisting of the present invention includes a special walking chassis, a telescopic tower body H, a swing arm luffing mechanism F, a folding arm mechanism, and an electrical control unit. The electrical control unit can be automatically controlled by a PLC programmable controller. . Overall structure of the present invention is as figure 1 shown.

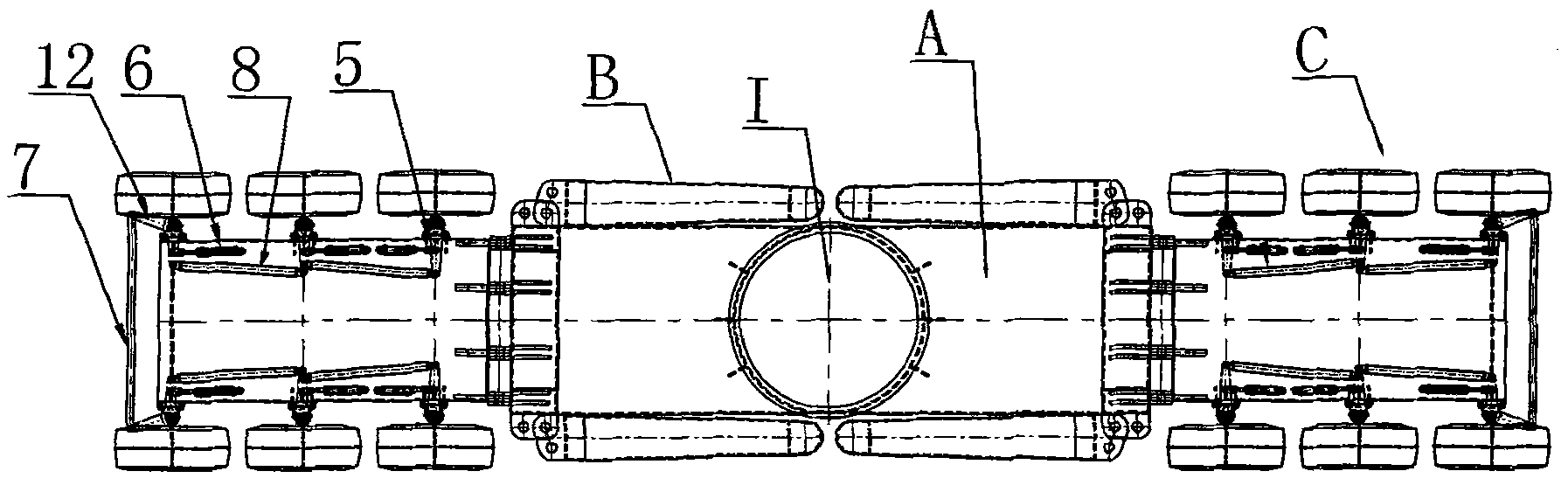

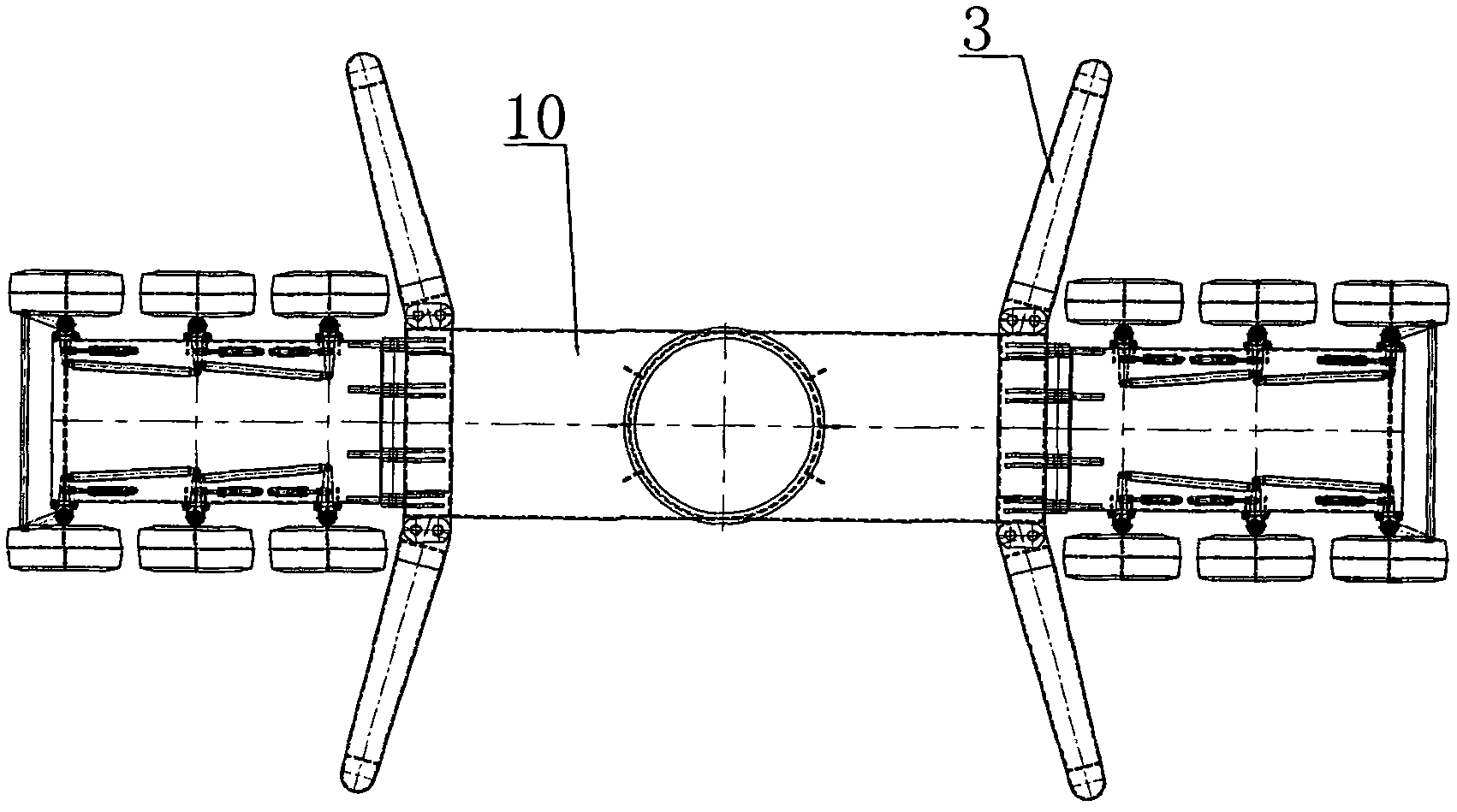

[0052] Such as figure 2 , image 3 As shown, the walking chassis of the present invention includes three parts, upper frame 20, lower frame A and slewing mechanism I, and lower frame A is divided into front, rear, and middle parts, which can solve the limitation of long-distance crane transportation on volume and Modular assembly; the front and rear parts are suspended with 6 walking tires, and the 6 tires are distributed on both sides. The whole vehicle has 12 tires. The driving tire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com