Method for preparing active carbon by mechanical-chemical method

A mechanochemical method and technology for preparing activated carbon, applied in the chemical industry, can solve the problems of high energy consumption, complex process and high reaction temperature, and achieve the effects of lowering reaction temperature, high efficiency of adsorbing pollutants, and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

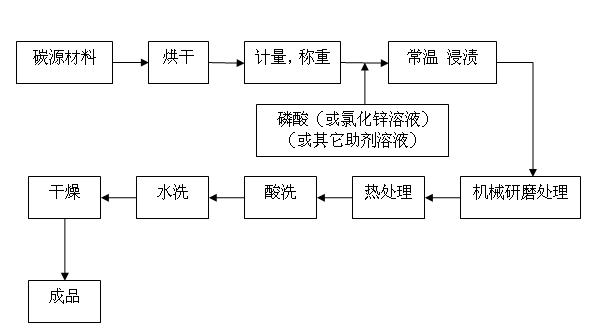

Image

Examples

Embodiment 1

[0019] A method for preparing activated carbon by mechanochemical method, the specific steps of the method are:

[0020] (1) According to the weight ratio of pure phosphoric acid to dry cedar shavings of 1:1, put the cedar shavings in a phosphoric acid solution with a mass fraction of 60% and stir them evenly and then place them at room temperature for 8 hours;

[0021] (2) Load the above materials into a ball mill, continuously grind for 30 minutes to an average particle size of 1 to 2 μm, and then conduct heat treatment at a temperature of 300°C for 60 minutes;

[0022] (3) Then the treated material is pickled with 10% hydrochloric acid solution for 30 minutes; then washed with deionized water to pH 6, and after the water is qualified, it is moved to an oven and dried at 120 ℃ for 1 hour to obtain performance Good powdery activated carbon with developed micropores.

Embodiment 2

[0024] A method for preparing activated carbon by mechanochemical method, the specific preparation steps of the method are:

[0025] (1) According to the weight ratio of pure zinc chloride to bone-dry pine wood chips of 2:1, put the pine wood chips in a zinc chloride solution with a mass fraction of 45% and then place them at room temperature for 5 hours;

[0026] (2) Load the above-mentioned materials into a vibrating mill, continuously grind for 40 minutes, until the average particle size is 1 to 2 μm, and then heat treatment at 500°C for 45 minutes;

[0027] (3) The treated material is then pickled with 10% hydrochloric acid solution for 30 minutes; then washed with deionized water to pH 6.5, and after the water is qualified, it is moved to an oven and dried for 1.5 hours at 105 ℃ to obtain performance Good powdery activated carbon with developed micropores.

Embodiment 3

[0029] A method for preparing activated carbon by mechanochemical method, the specific preparation steps of the method are:

[0030] (1) According to the weight ratio of pure potassium hydroxide to dry husks of 3:1, put the husks in potassium hydroxide with a mass fraction of 70%, stir well, and then place them at room temperature for 2 hours;

[0031] (2) Load the above-mentioned materials into the grinding equipment, and continuously grind for 60 minutes until the average particle size is 1~2μm, and then heat treatment at 700℃ for 30 minutes;

[0032] (3) The treated material is then pickled with 10% hydrochloric acid solution for 30 minutes; then washed with deionized water to pH 7, and after the water is qualified, it is transferred to an oven and dried at 110 ℃ for 2 hours to obtain performance Good powdery activated carbon with developed micropores.

[0033]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap