Self-regulating spray nozzle of dyeing machine

A self-adjusting and dyeing machine technology, applied in spray/jet textile material processing and other directions, can solve the problems of time-consuming and laborious, low dyeing efficiency, and reduced fabric types, and achieve high dyeing efficiency, improved versatility, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

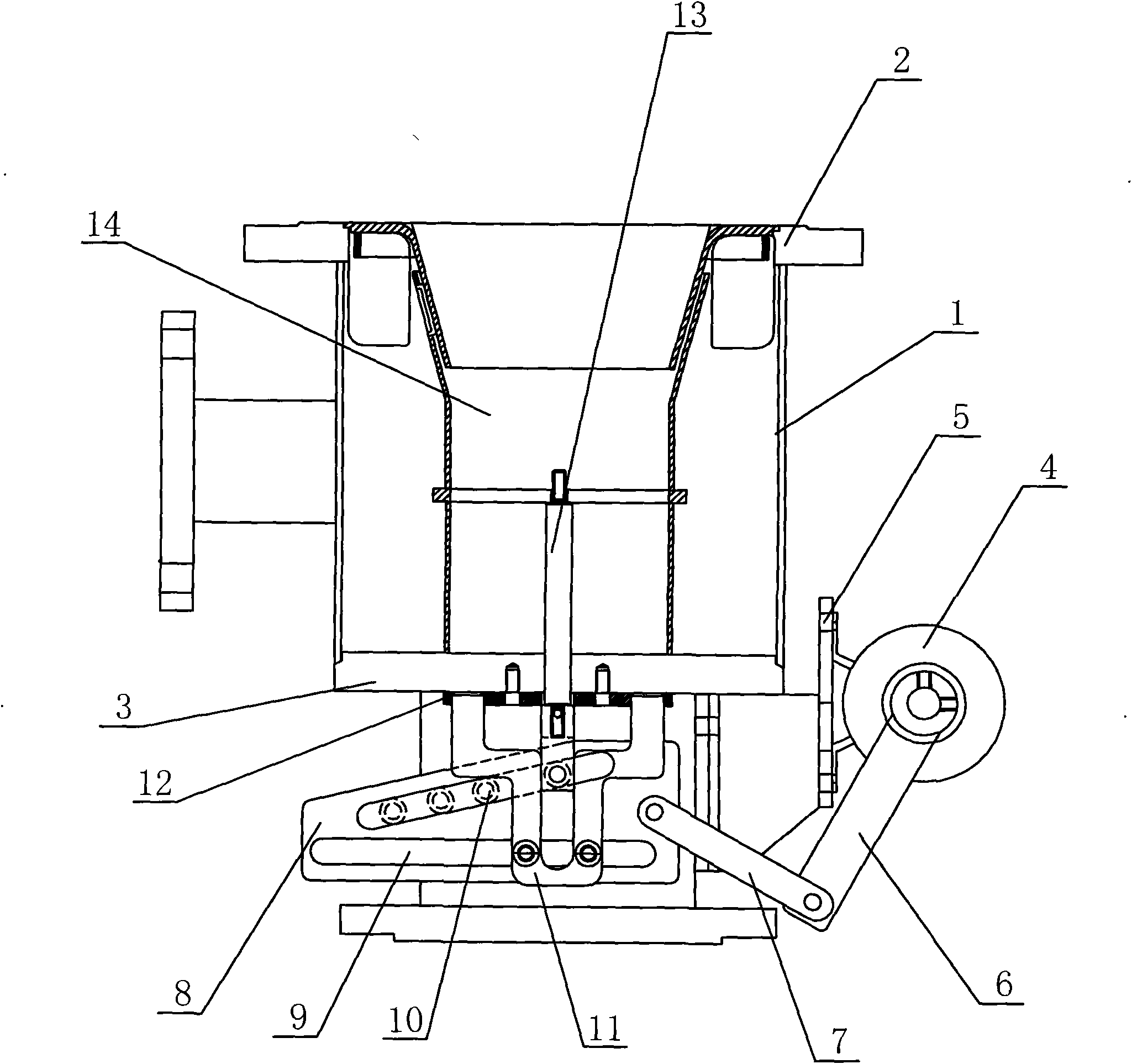

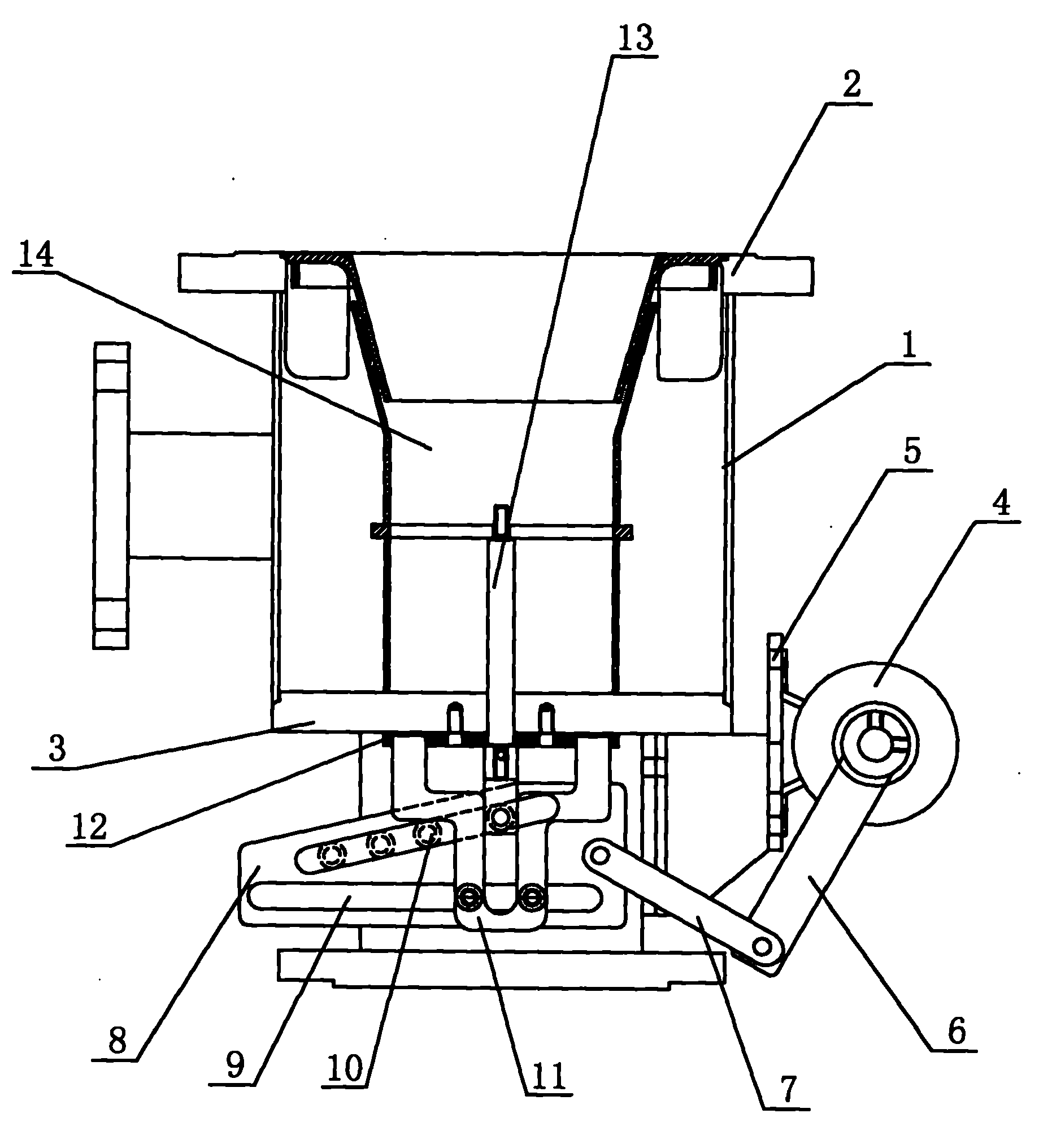

[0013] Please refer to figure 1 as shown, figure 1 It is a structural schematic diagram of the self-regulating nozzle of the dyeing machine of the present invention. In this embodiment, a self-regulating nozzle of the dyeing machine includes a nozzle 1 connected to the barrel of the dyeing machine and a nozzle 14 arranged inside the nozzle 1 , the top of the nozzle 1 is provided with a nozzle housing connection flange 2, corresponding to the bottom is provided with a nozzle bottom flange 3 and a nozzle bottom plate 12, and a nozzle is arranged between the nozzle 1 and the cylinder body of the dyeing machine Bracket 11, the self-adjusting nozzle of the dyeing machine also includes a speed reducer 4 connected to the servo motor, the speed reducer 4 is installed on the nozzle pipe 1 through the fixing plate 5, and the speed reducer 4 passes through the nozzle rod 6 Connect the oblique wedge-shaped nozzle slider 8 with the nozzle connecting rod 7, a pull rod 13 is connected betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com