Fuel cell engine exhaust silencer

An exhaust muffler and fuel cell technology, which is applied to fuel cells, fuel cell parts, engine components, etc., can solve the problems of water accumulation, blockage, and noise reduction effect of sound-absorbing materials, and achieve effective recovery and reduction of exhaust gas. Noise, the effect of ensuring water balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

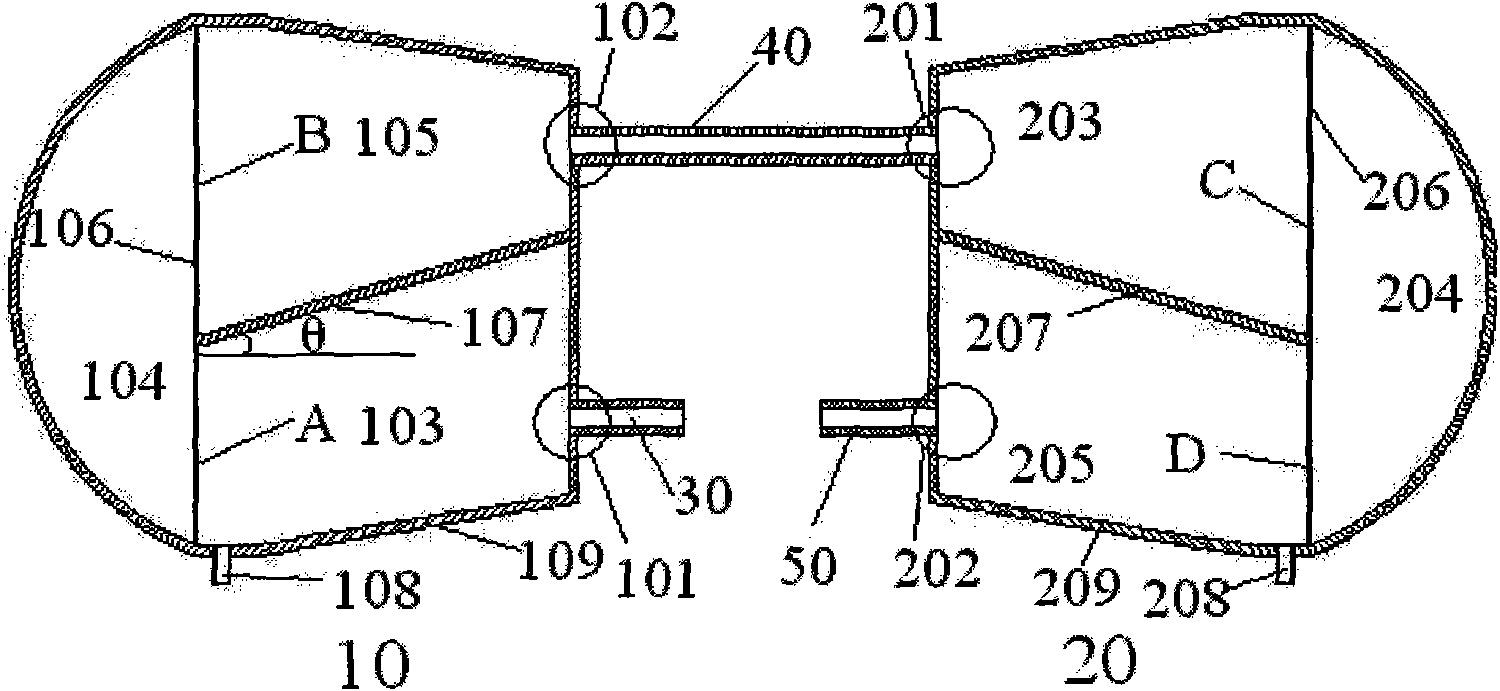

[0015] See figure 1 , is a structural schematic diagram of the exhaust muffler used in the fuel cell engine involved in the present invention. It includes two cavities 10, 20, and two openings 101, 102, 201, 202 are respectively provided on the two cavities 10, 20, which are the first, second openings 101, 102 and the second openings on the first cavity 10 respectively. The third and fourth openings 201 and 202 on the second cavity 20 . Each of the above-mentioned openings is connected with the pipe, and the place where the opening is connected with the pipe is a sudden change interface. Specifically, the first opening 101 is externally connected to the intake pipe 30 , the second opening 102 is connected to the third opening 201 (ie, the first cavity 10 and the second cavity 20 ) through the connecting pipe 40 , and the fourth opening 202 is externally connected to the exhaust pipe 50 . The cross-sectional area of the pipe inlet is suddenly reduced compared with the cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com