Heat storage and heat supply device for phase-change material

A technology of phase change materials and heating devices, which is applied in heat storage equipment, household heating, heating systems, etc., can solve problems such as inability to make full use of heat, and achieve simple structure, stable heat release, and high heat exchange efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

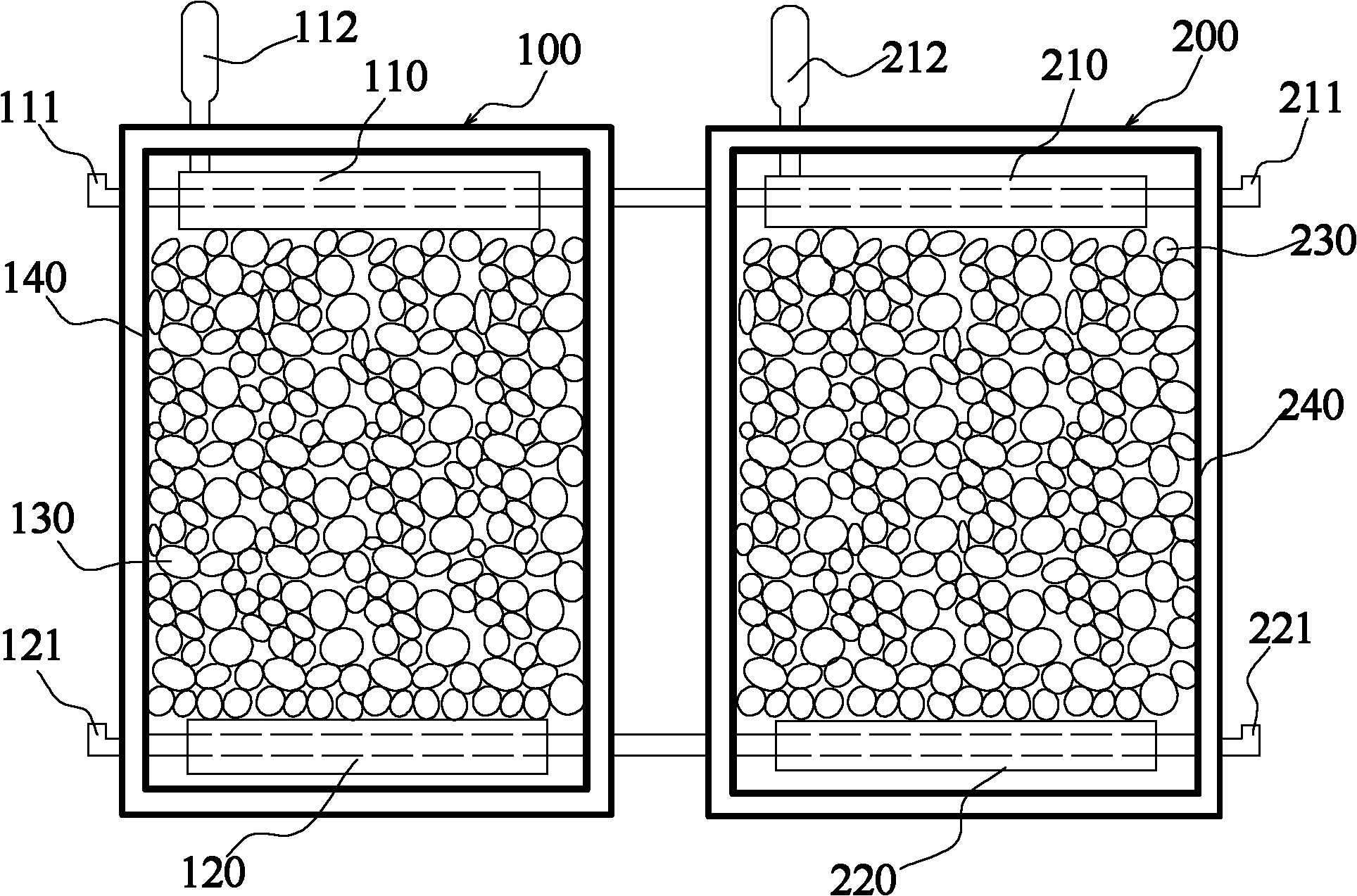

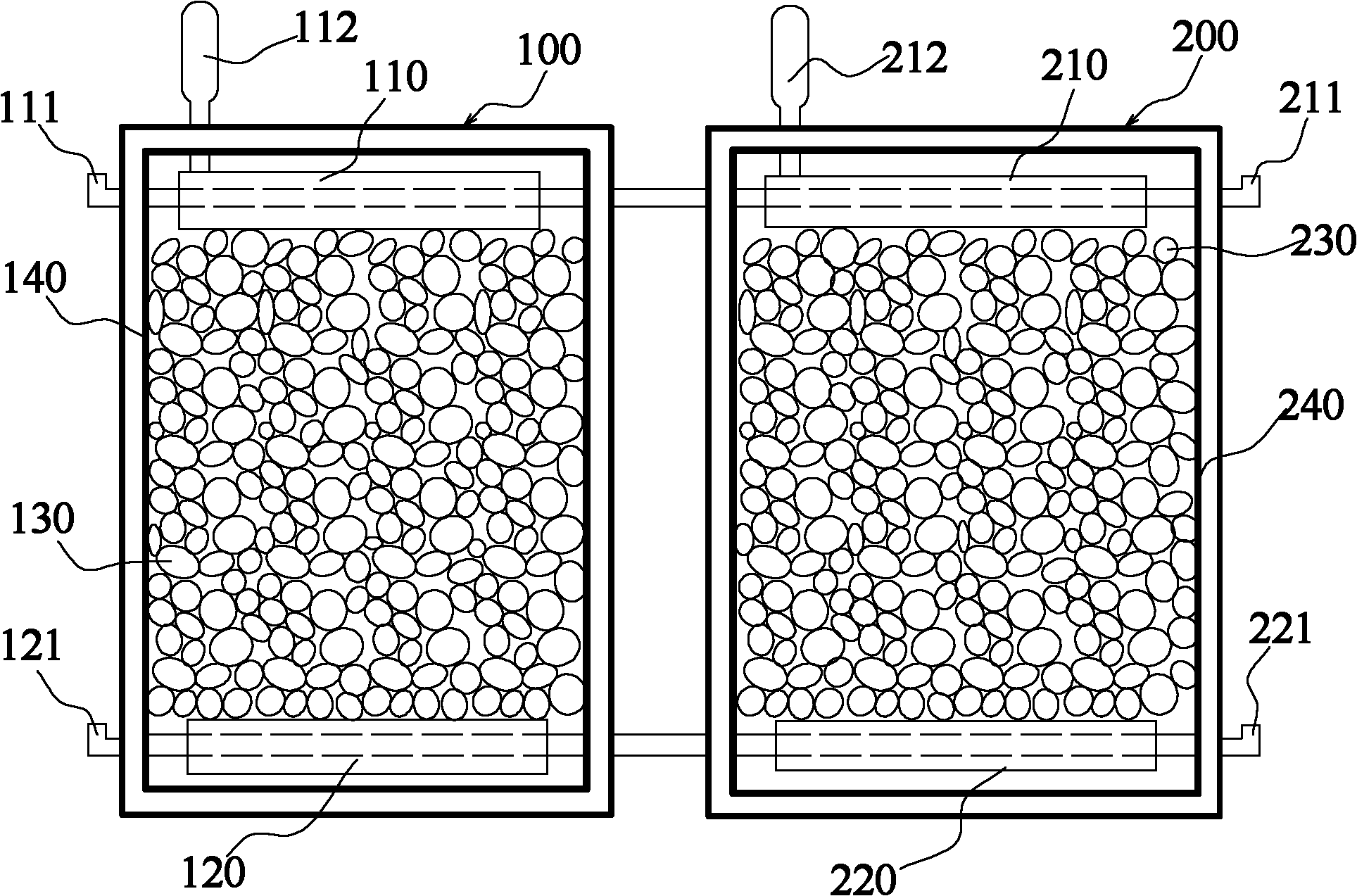

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in combination with illustrations and specific implementation methods.

[0013] As one of the embodiments, low-temperature heat storage balls 130 are stacked in the heat storage box 100, and the low-temperature heat storage balls 130 are filled with phase change materials with a relatively low phase transition temperature, and a heat-taking heat exchanger is arranged on the upper part of the heat storage box 100. 110, the heat extraction heat exchanger 110 is provided with a heat extraction fluid inlet 111, and the lower part of the heat storage tank 100 is provided with a heat supply heat exchanger 120, and the heat supply heat exchanger 120 is provided with a heat supply fluid outlet 121; High-temperature heat storage balls 230 are piled up in 200, and the high-temperature heat storage ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com