Method for improving weighing precision of charging system and device thereof

A feeding system and precision technology, which is applied in the field of feeding system to achieve the effects of improving production efficiency, increasing production cost and improving weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

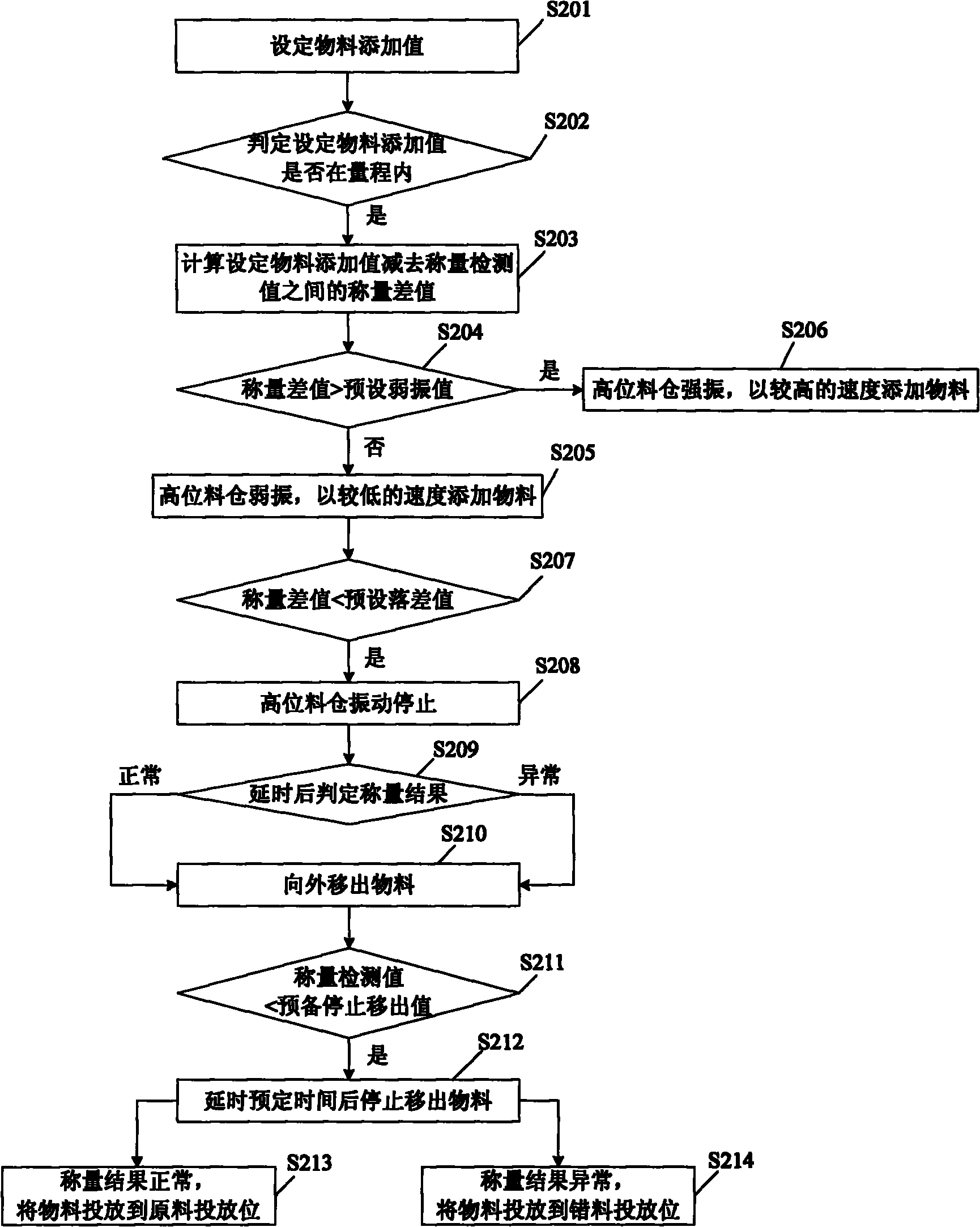

[0043] Such as Figure 5 The flow chart of the method for improving material weighing accuracy shown in this implementation includes:

[0044] S11, installing a preset compensation module with a standard weight greater than the maximum positive zero drift value and the maximum negative zero drift value of the weighing hopper on the weighing hopper to generate an original weighing value. There is no fixed requirement on the shape of the preset compensation module, which is convenient to pick and place, such as standard weights. When calibrating the weighing hopper, the preset compensation module is usually removed, and the preset compensation module is put on after calibration.

[0045]Due to the existence of the preset compensation module, there is always a positive original weighing value in the weighing hopper before the material is weighed. Generally, the maximum positive zero drift value and the maximum negative zero drift value are not too large, for example, 20 kg, the...

Embodiment 2

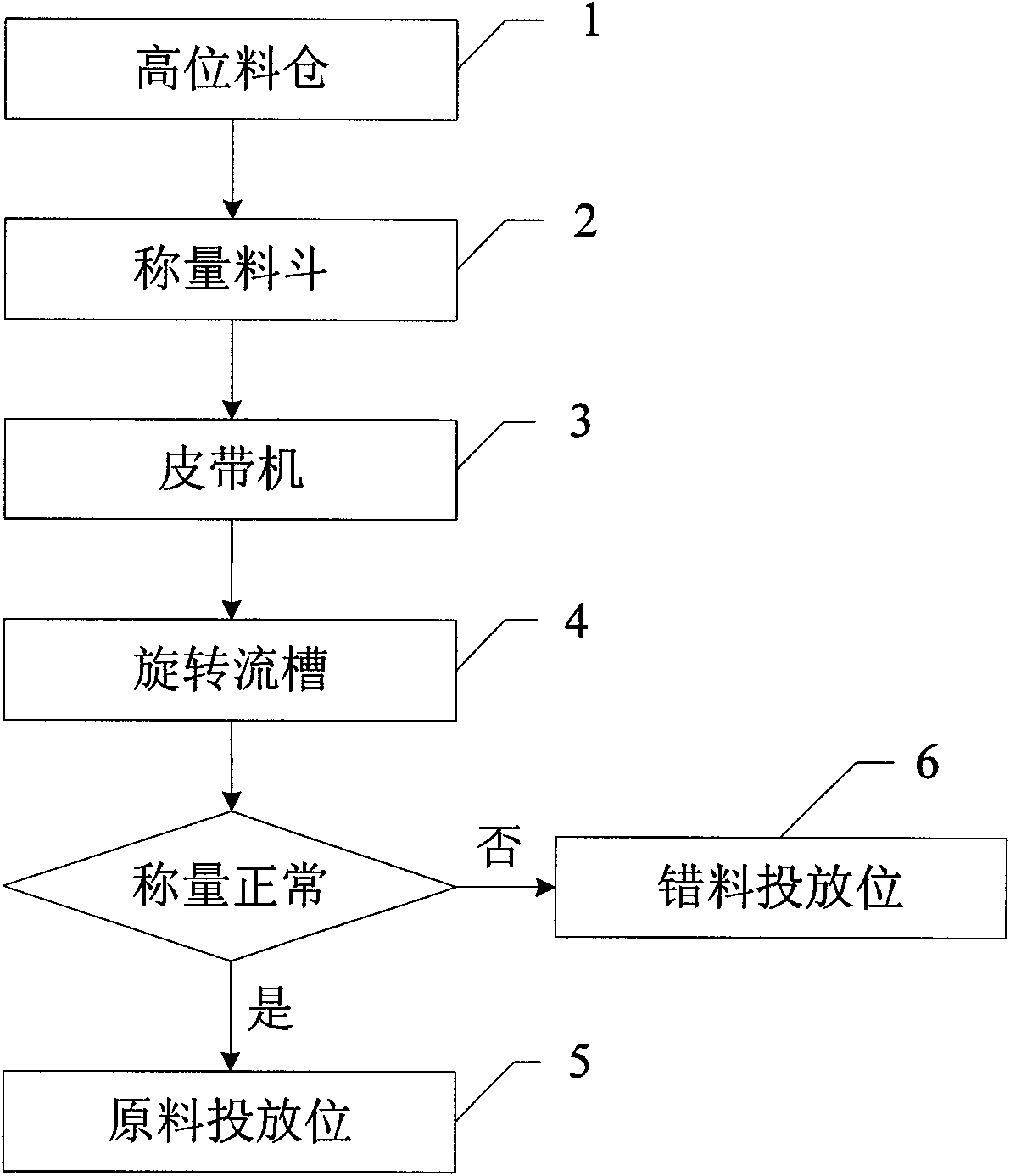

[0052] On the basis of Example 1, as Figure 6 The flow chart of the method for improving the weighing accuracy of the feeding system shown in this implementation, and image 3 Compared with the flow chart of the method for the weighing of the charging system in the prior art shown, the difference only lies in:

[0053] S603: Calculate the weighing difference of the added value of the set material minus the actual value of the current material. Replaces the prior art S203. The purpose of the replacement is to shield the problem of inaccurate weighing caused by the zero point drift, which has been introduced in detail in the first embodiment.

[0054] S611: Judging whether the difference between the weighing detection value minus the original weighing value is less than a predetermined stop-out value. Replaces the prior art S211. The weighing detection value minus the original weighing value is actually the current actual value of the material, the minimum value can reach z...

Embodiment 3

[0101] Such as Figure 7 The schematic diagram of the structure of the device for improving the weighing accuracy of materials shown in this implementation includes:

[0102] The preset compensation module 20 whose standard weight is greater than the maximum positive zero drift value and the maximum negative zero drift value of the weighing hopper 2 is installed on the weighing hopper 2 to generate the original weighing value. There is no fixed requirement on the shape of the preset compensation module, which is convenient to pick and place, such as standard weights.

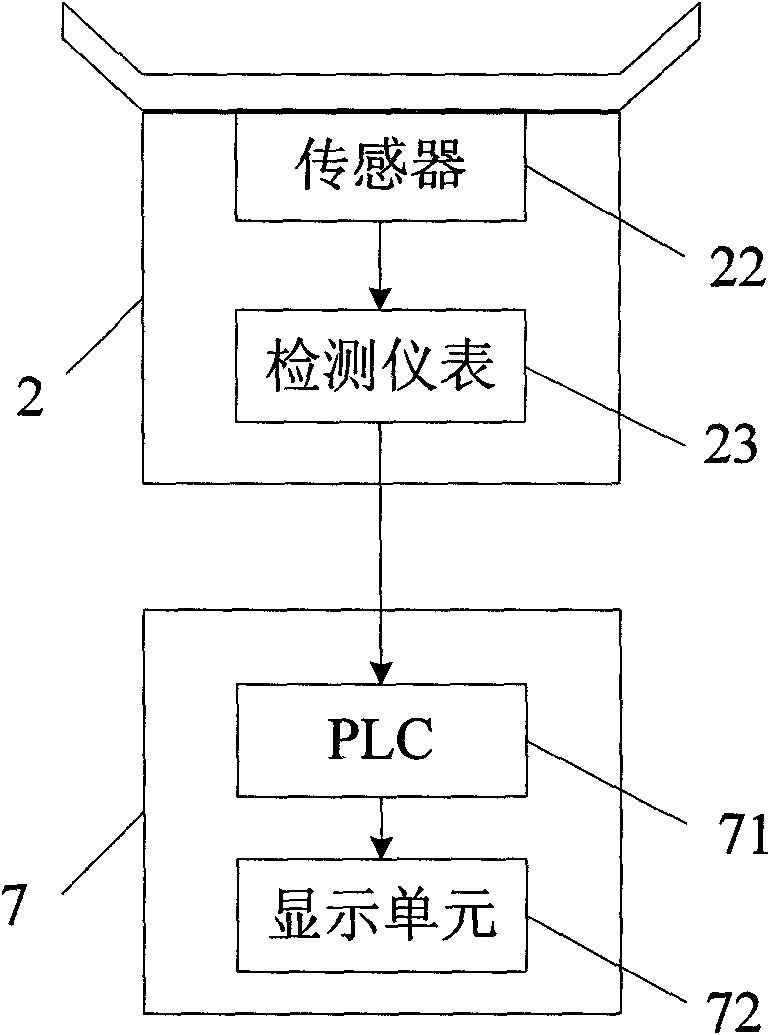

[0103] The control unit 7 includes a calculation unit 701 , a first signal output unit 702 and a second signal output unit 703 .

[0104] The calculation unit 701 is used to calculate the current actual value of the upper material in the weighing hopper 2 according to the original weighing value and the weighing detection value of the weighing hopper 2 . The current actual value can be directly obtained by sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com