Turbidity measuring device and a method for determing a concentration of a turbidity-causing material

A measurement device, turbidity technology, applied in the direction of measurement device, scattering characteristic measurement, suspension and porous material analysis, etc., can solve the problems of weak FAL signal, difficult to accurately determine the concentration of turbidity substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

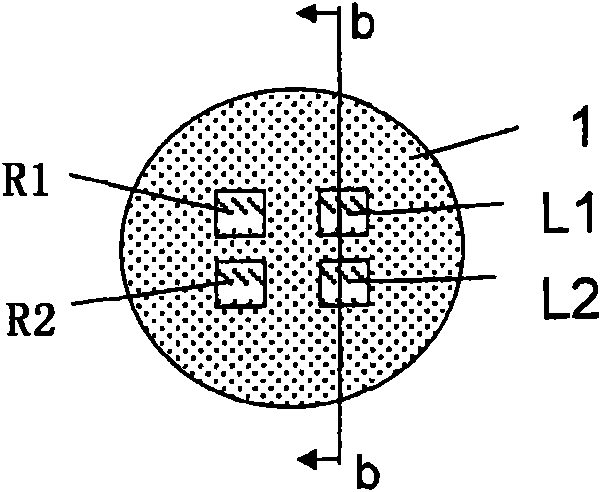

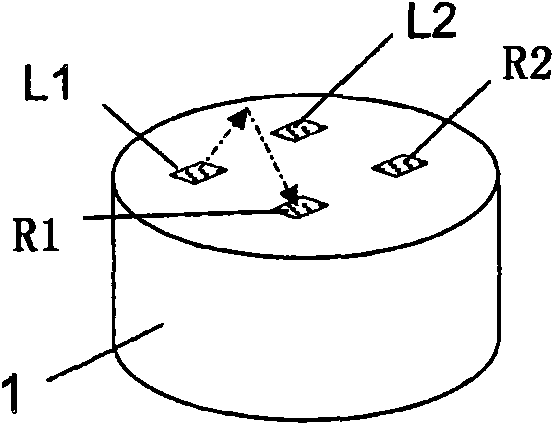

[0044] Figure 1a The probe of the turbidity measuring device shown consists of a substantially cylindrical metal housing made of stainless steel, at the ends of which are provided four windows (the corners of which define a rectangle), which direct the first light source L 1 and the second light source L 2 , the first receiver R 1 and the second receiver R 2 Sealed away from the environment surrounding the probe; wherein the first light source L 1 and the second light source L 2 Radiant energy enters and exits through the window.

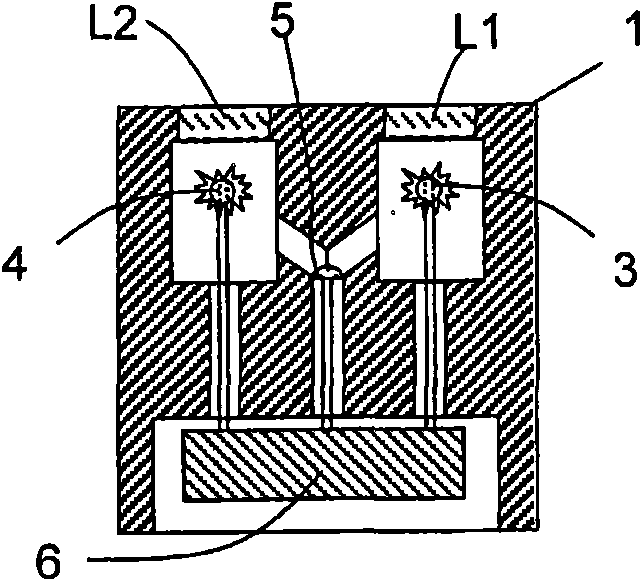

[0045] Such as Figure 1b As shown, the light source L 1 and L 2 It includes a first flashlight 3 and a second flashlight 4, wherein monitoring diodes 5 are arranged between the flashlights, and the distribution records the light intensity of the first flashlight and the second flashlight.

[0046] The first flashlight 3, the second flashlight 4 and the monitoring diode 5 and the first receiver R 1 and the second receiver R 2 Each photodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com