Organic electro-luminescence display unit and manufacturing thereof

A technology of electroluminescence and display unit, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc. It can solve the problems of inability to display brightness, affect the accuracy of light sensors, and effectively reduce the power consumption of organic electroluminescence displays, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

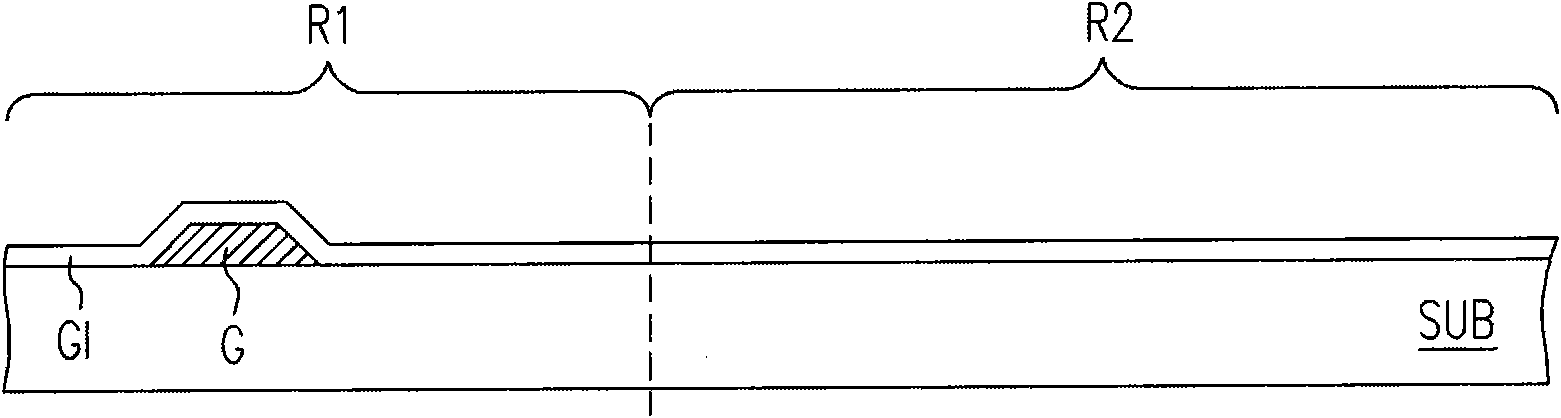

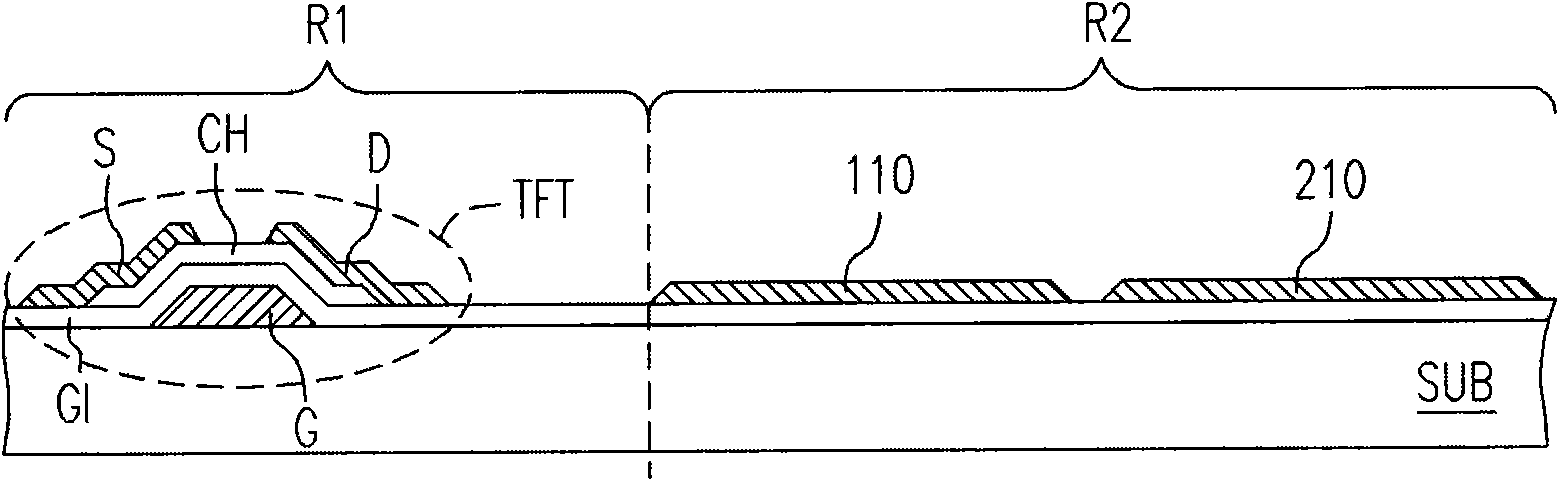

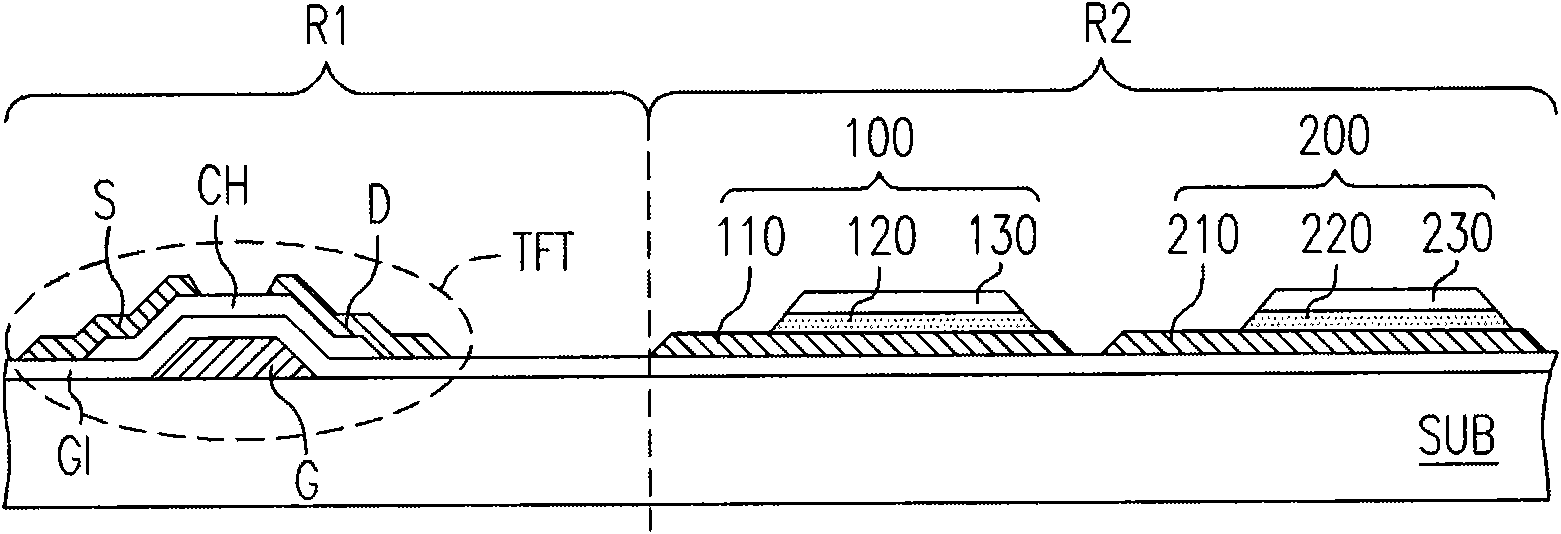

[0060] Figure 1A to Figure 1E It is a schematic cross-sectional view of the manufacturing process of the organic electroluminescent display unit according to the first embodiment of the present invention. First, please refer to Figure 1A , providing a substrate SUB, the substrate SUB has a display region R1 and a peripheral region R2. Then at least one gate G is formed on the substrate SUB ( Figure 1A Only one gate is shown in the figure), and a gate insulating layer GI is formed on the substrate SUB to cover the gate G. In other words, the gate insulating layer GI covers the display region R1 and the peripheral region R2 mentioned above. In this embodiment, the material of the substrate SUB is, for example, glass, quartz, organic polymer, opaque / reflective material (such as conductive material, wafer, ceramic, or other applicable material), or other applicable Material. In addition, the above-mentioned display region R1 is a region for forming organic electroluminescen...

no. 2 example

[0077] Figure 2A to Figure 2E It is a schematic cross-sectional view of the manufacturing process of the organic electroluminescence display unit according to the second embodiment of the present invention. The manufacturing process of the organic electroluminescence display unit of this embodiment is similar to that of the first embodiment, but the main difference between them is that the connection mode between the first light sensor 100 and the second light sensor 200 is different. Such as Figure 2D As shown, the first transparent top electrode 130 is only electrically connected to the leftmost bridge pattern 330, the second reflective bottom electrode 210 is only electrically connected to the rightmost bridge pattern 330, and the first reflective bottom electrode 110 is electrically connected to the second The two transparent top electrodes 230 are electrically connected to each other through the middle bridge pattern 330 and the light-shielding pattern 320 .

[0078] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com