Mixing dynamic balance method for crossing outer rotor

An external rotor, balanced technology, applied in the direction of electric components, control mechanical energy, electrical components, etc., can solve the problems of dangerous, complex, complex and changeable processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

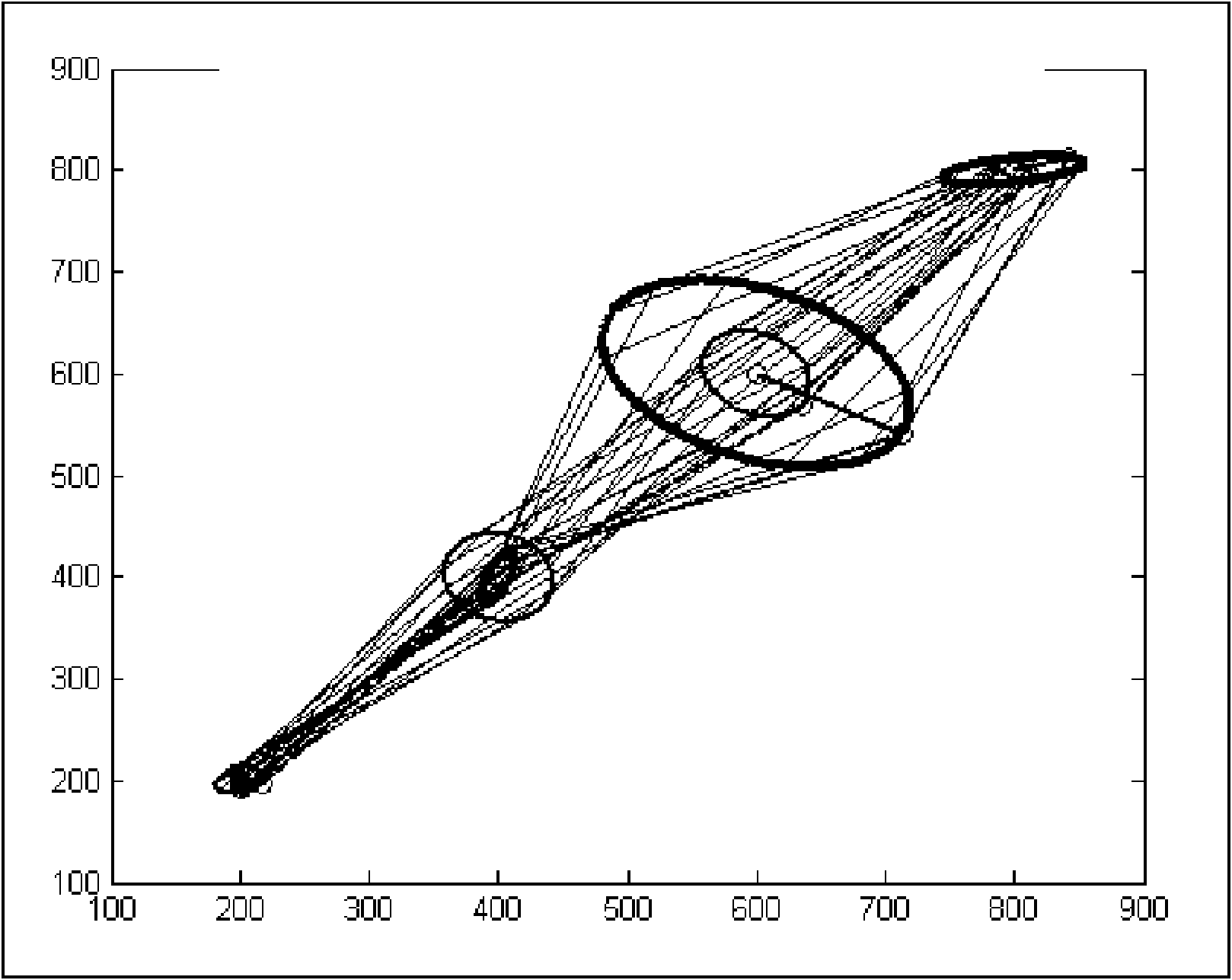

[0058] In order to verify the superiority of the cross-outer-rotor hybrid dynamic balancing method of the present invention, the present invention will be further described in detail below in conjunction with embodiments.

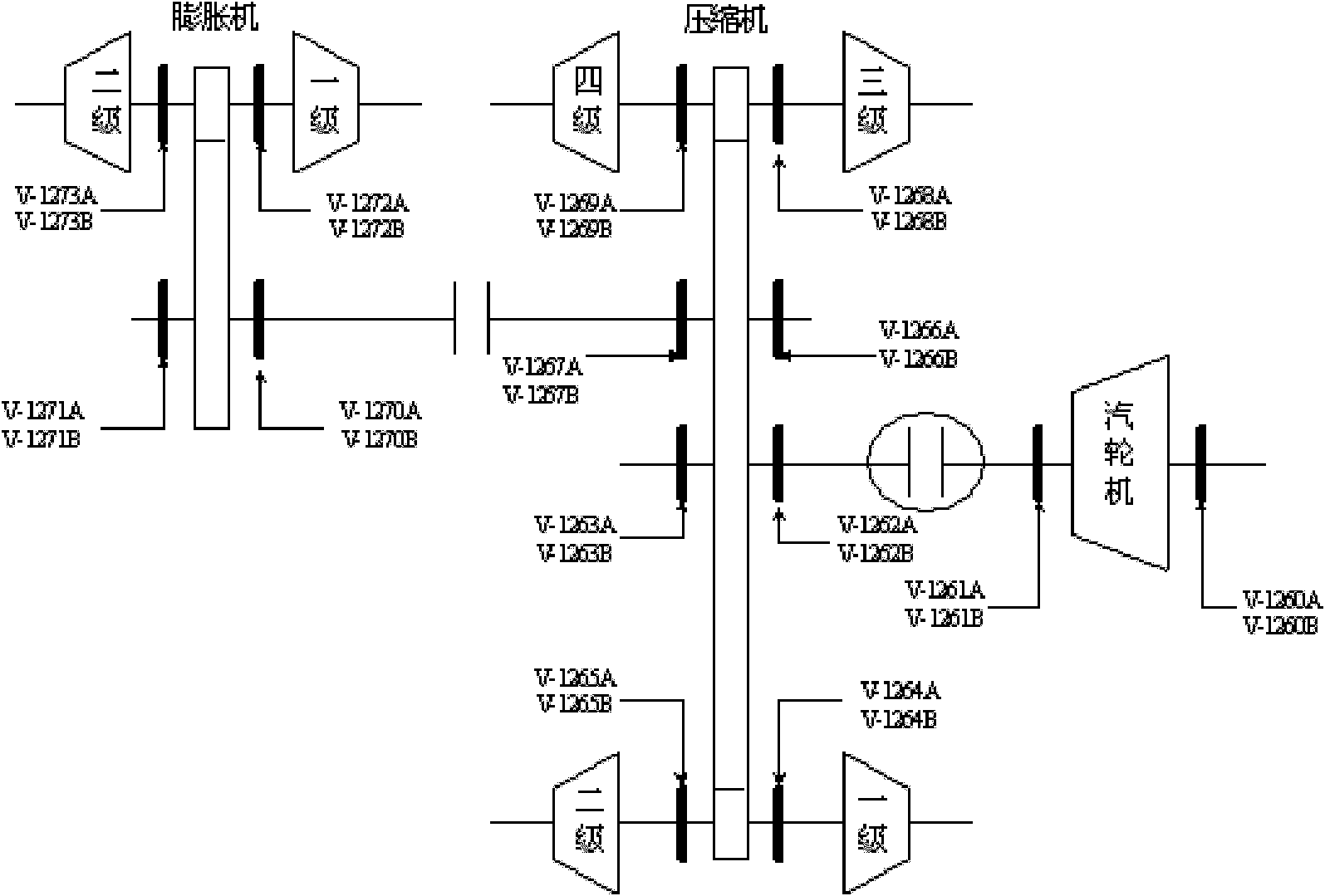

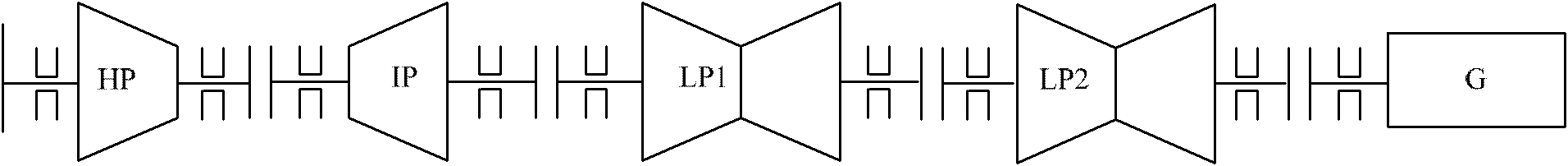

[0059] The cross-outer rotor hybrid dynamic balancing method of the present invention is applied to the steam turbine shaft of a domestic petrochemical compressor unit, and the experimental bench structure based on the high, medium and low pressure rotors of the steam turbine generator set, and the smoke machine. The effect of the dynamic balance experiment Can verify the ability of the hybrid dynamic balance of this invention.

[0060] The detailed description of the cross-outer rotor hybrid dynamic balancing method is as follows:

[0061] Step one, select the appropriate balance surface: the coupling is the extended end of the two adjacent rotors. In the on-site unit structure, the coupling is generally exposed outside the unit or can be exposed by simply openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com