Oxygen surface humidifying device

A surface humidification part and humidification technology, which is applied in the field of oxygen surface humidification devices, can solve the problems of invariable humidification effect, obvious noise in humidification process, inconvenient clinical operation, etc., so as to facilitate liquid consumption and improve humidification effect. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

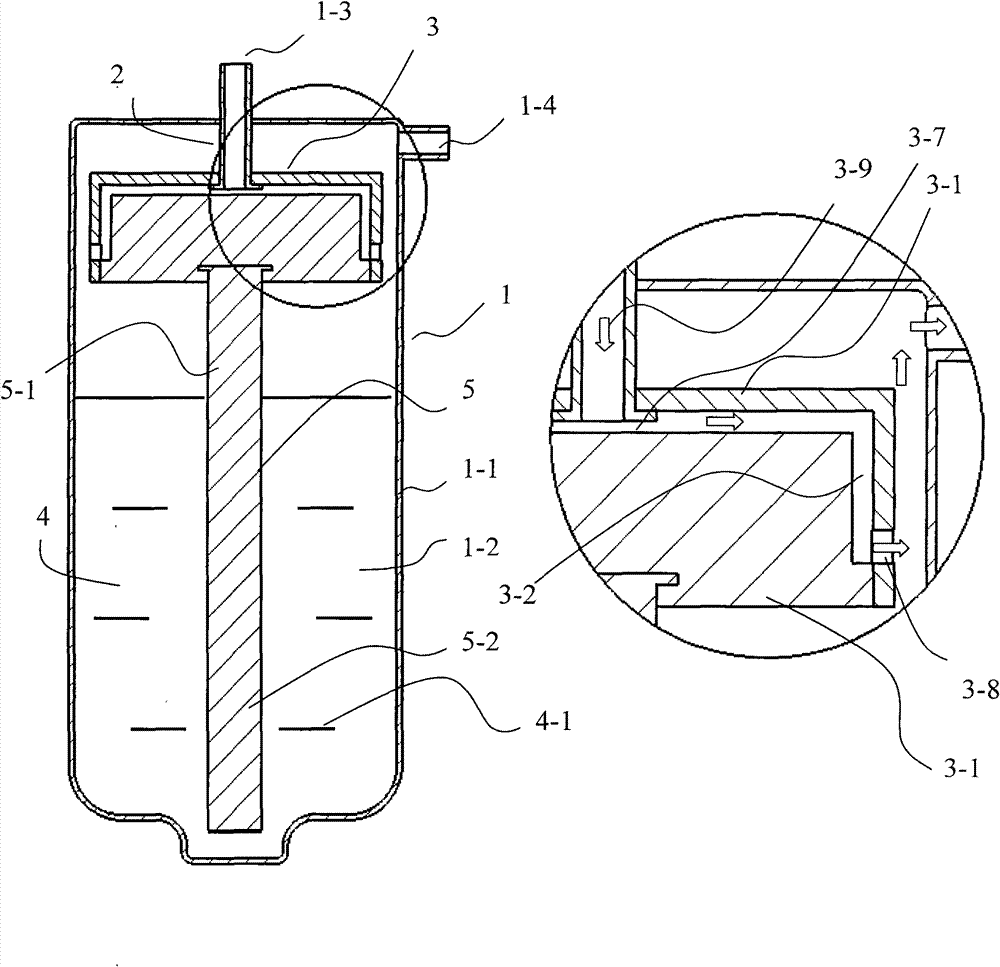

[0022]Embodiment 1: as figure 1 As shown, the main shell 1 of the surface humidification device is composed of two parts, which are injection-molded with PC resin and ABS resin, and are cylindrical bottles. Partially integrated, the average thickness of the main shell wall 1-1 is 1.5mm, the volume of the main shell inner cavity 1-2 is 500ml, the volume of the humidification liquid storage part 4 is 300ml, and the main shell 1 is provided with air inlets 1-3, The air outlet 1-4, the input pipeline 2 are hard or soft plastic pipes, which are closely connected with the main shell 1, and its inner cavity communicates with the air inlet 1-3, and the surface wetting part 3 can be controlled by the surface wetting part. The water-absorbing body 3-1 is independently composed of PVA (polyvinyl alcohol) material, which is formed by cross-linking and foaming in the mold, or PP, PET non-woven fabrics can be melted or sewn, and the water-absorbing body 3- One end 3-7 of the cavity in 1 co...

Embodiment 2

[0023] Embodiment 2: as Figure 4 As shown, the humidification liquid storage part 4 of the surface humidification device is independently configured 9, and 360ml of humidification liquid 4-1 is filled in it, and the opening 9 on the casing 9-1 of the independently configured humidification liquid storage part 9 -2 The thread 9-3 connected to the main shell is sealed and connected with the main shell 1, and at the same time, the water-absorbable body of the humidification liquid delivery part on the independently configured humidification liquid storage part 9 is connected to the inner cavity of the main shell 1-2 The water-absorbable body 3-1 of the surface humidification part is connected, and it can also be connected with the part of the water-absorbable body 3-1 of the surface humidification part that protrudes outside the inner cavity 1-2 of the main shell; the independently configured humidification liquid storage The housing 9-1 of the part 9 is provided with a liquid i...

Embodiment 3

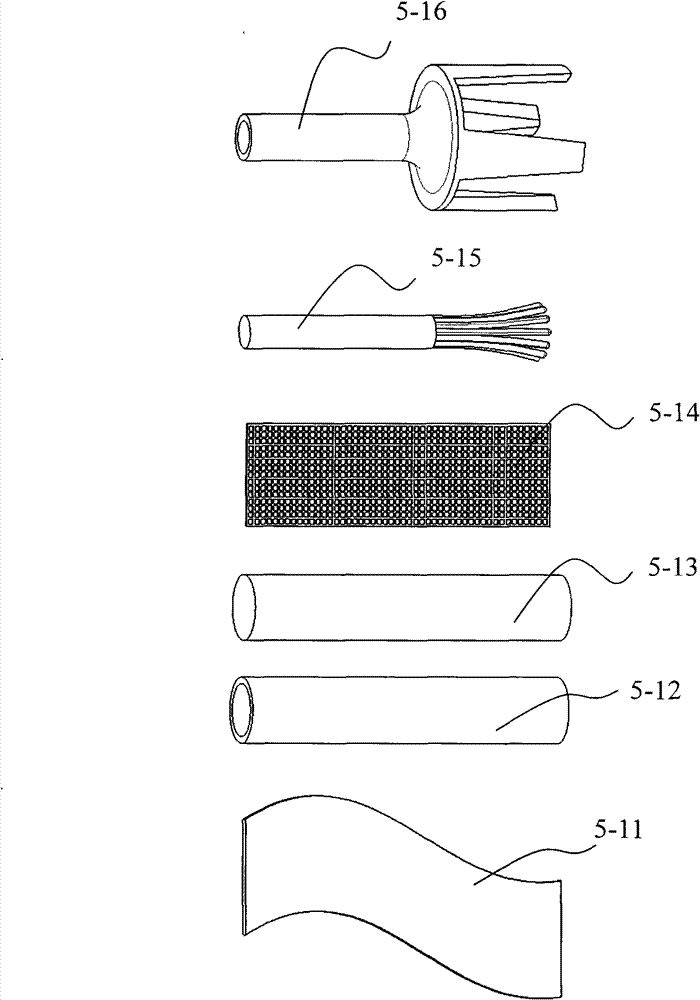

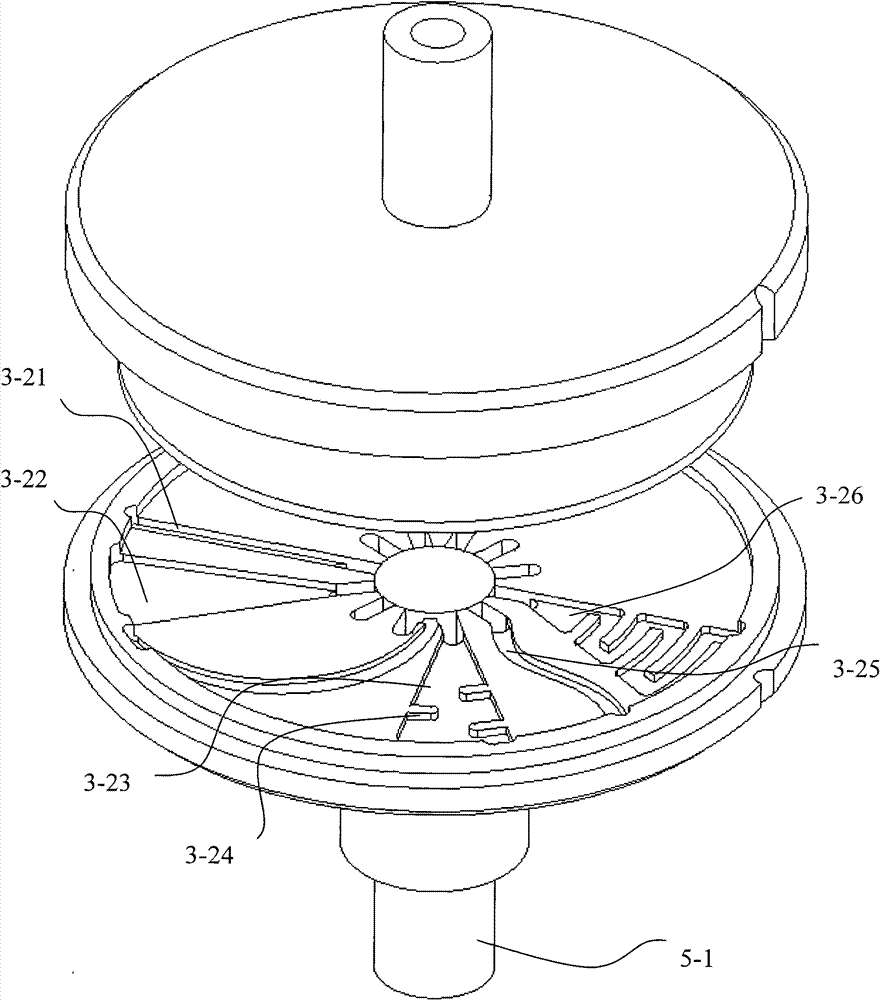

[0024] Embodiment 3: as Figure 5-8 As shown, the main shell 1 of the surface humidification device is composed of two parts, which is a cylindrical bottle with an outer diameter of 68 mm, a height of 180 mm, and a wall thickness of 1.5 mm. ABS resin is used for injection molding, and the lower part is blow-molded by transparent PET material. The upper and lower parts of the main shell are sealed and connected by thread 1-7. If necessary, a sealing ring is added. There are installation positioning grooves 1-8 outside the shell, and the air inlet and outlet are provided. The sealing cap 1-6 may be sealed with a heat-sealing film. The surface wetting part 3 is composed of the surface wetting part absorbable body 3-1 and the upper and lower shells 3-3. The upper and lower shells 3-3 will absorb the water body 3. -1 is sealed in it, the dividing ribs 3-4 on the inner surface of the upper and lower shells symmetrically press against the water-absorbable body 3-1, and communicate wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com