Method for evaluating pre-processing effect of high-efficient straw methane utilization

A straw pretreatment and evaluation method technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of different effects, large differences in cost input, lack of scientific indicators and basis, etc., to achieve Easy to use and operate, low monitoring cost and simple indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

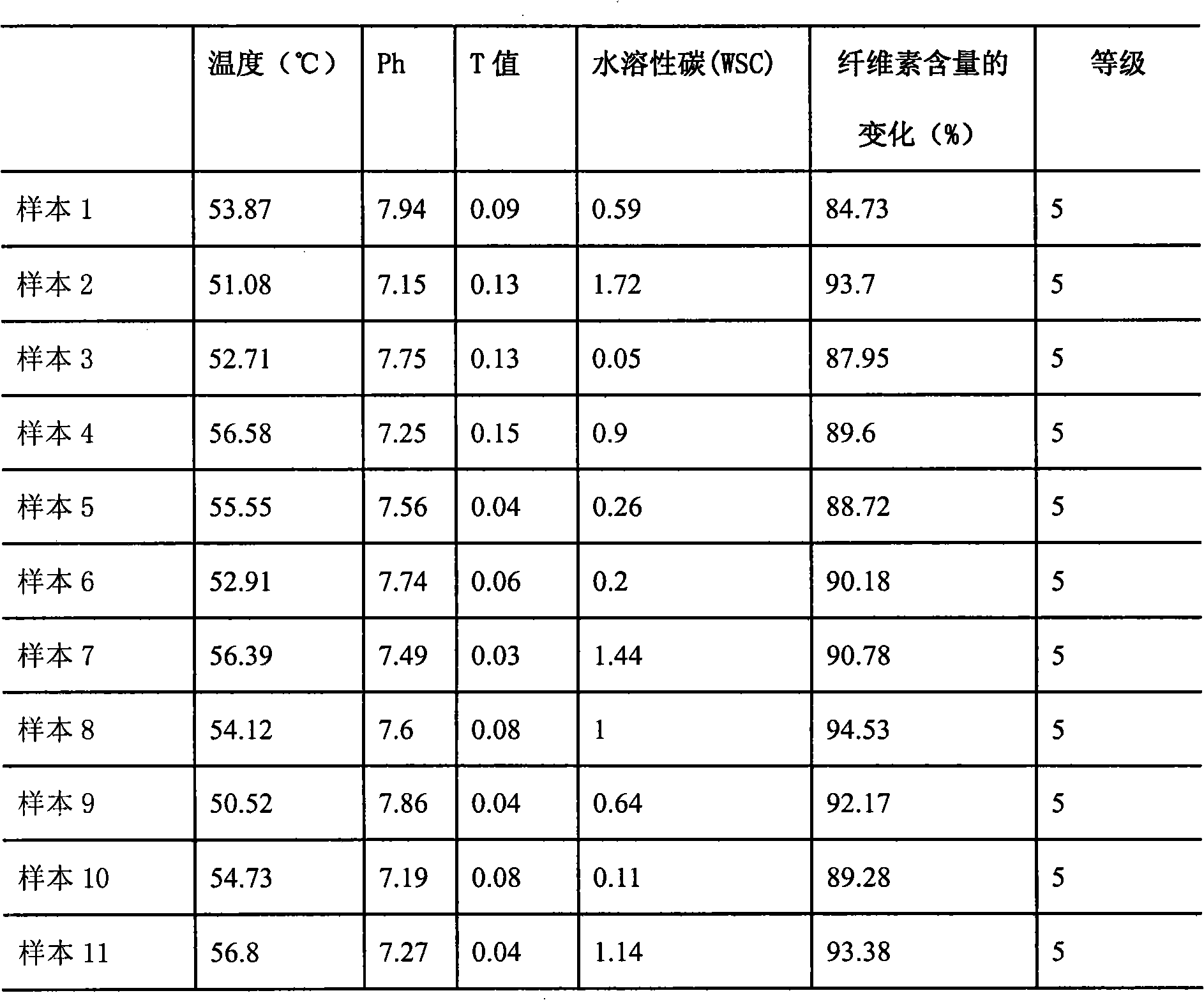

[0021] For the same pretreatment method, the straws treated for more than 6 days (including 6 days) were sampled every 2 days, and a total of 4 samples were taken. The temperature (°C), Ph, C, N, water soluble carbon (WSC) and cellulose content of the samples were determined. The determination of temperature and Ph value is the measured value of raw material pretreatment; the determination of C, N, water-soluble carbon (WSC) and cellulose content is carried out according to the national monitoring standard.

[0022] The calculation method of T value in the evaluation index is as follows:

[0023]

[0024] The change of the content of cellulose is:=(starting point cellulose X 0 -End Cellulose X i ) / starting point cellulose X 0

[0025] BP neural network training samples

[0026] The training value corresponding to each sample is shown in Table 2, and the random value method is used to obtain the value. The number of samples is determined according to the training requi...

Embodiment 2

[0049] The same pretreatment method of embodiment 2, the evaluation of pretreatment effect in different pretreatment stages

[0050] 1. Use chemical accelerators or biological accelerators to stalks to take samples on 6 days, 8 days, 10 days and 12 days of pretreatment, and measure the temperature (°C), Ph, C, N, water-soluble carbon (WSC) and Cellulose content, calculate the value of each index in different pretreatment stages.

[0051] 2. Use the training sample set of the trained ANN combined with the evaluation index to evaluate the preprocessing effect of the four stages.

[0052] 3. Finally, each preprocessing effect is determined according to the scoring value of the simulation evaluation. The higher the score, the better the processing effect.

Embodiment 3

[0054] Different pretreatment methods are used for the same kind of straw. When the treatment is basically finished, samples are taken to measure the temperature (°C), Ph, C, N, water-soluble carbon (WSC) and cellulose content of the sample, and the material content of different pretreatment methods is calculated. The value of each indicator. The rest of the steps are the same as those in Embodiment 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com