Medium-high temperature carbon crystal electric heating material, medium-high temperature carbon crystal electric heating plate and relevant preparation method

An electric heating material, medium and high temperature technology, applied in medium and high temperature carbon crystal electric heating materials, medium and high temperature carbon crystal electric heating plates and related preparation fields, can solve problems such as difficulty in ensuring construction quality, temperature risk of carbon fiber materials, inability to use radiators, etc., to achieve Effects suitable for large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0033] The modulus indicators of the selected carbon fiber raw materials are: acrylocyanine, resistance 10K modulus, fiber length 2-3 mm, and no glue.

[0034] The preparation of carbon crystal powder comprises the following steps successively:

[0035] a) Use a strong magnetic field above 30,000 gauss to strengthen the electrode polarity;

[0036] b) Use a high-power electronic ball mill for deep processing, and the ball milling time is 2 to 3 hours until the carbon crystal powder with uniform particles of 1000 to 3000 mesh is produced to form a carbon crystal raw material, and the surface temperature of the carbon crystal raw material can reach 100 °C Above, and reach a higher 250 ~ 300 ℃.

preparation Embodiment 2

[0038] The modulus indicators of the selected carbon fiber raw materials are: acrylocyanine, resistance 10K modulus, fiber length 3-4mm, and no glue. The carbon crystal powder is prepared according to the method in Example 1 to form a carbon crystal raw material. The surface temperature of the carbon crystal raw material can reach above 100° C., and reach a relatively high 250-300° C.

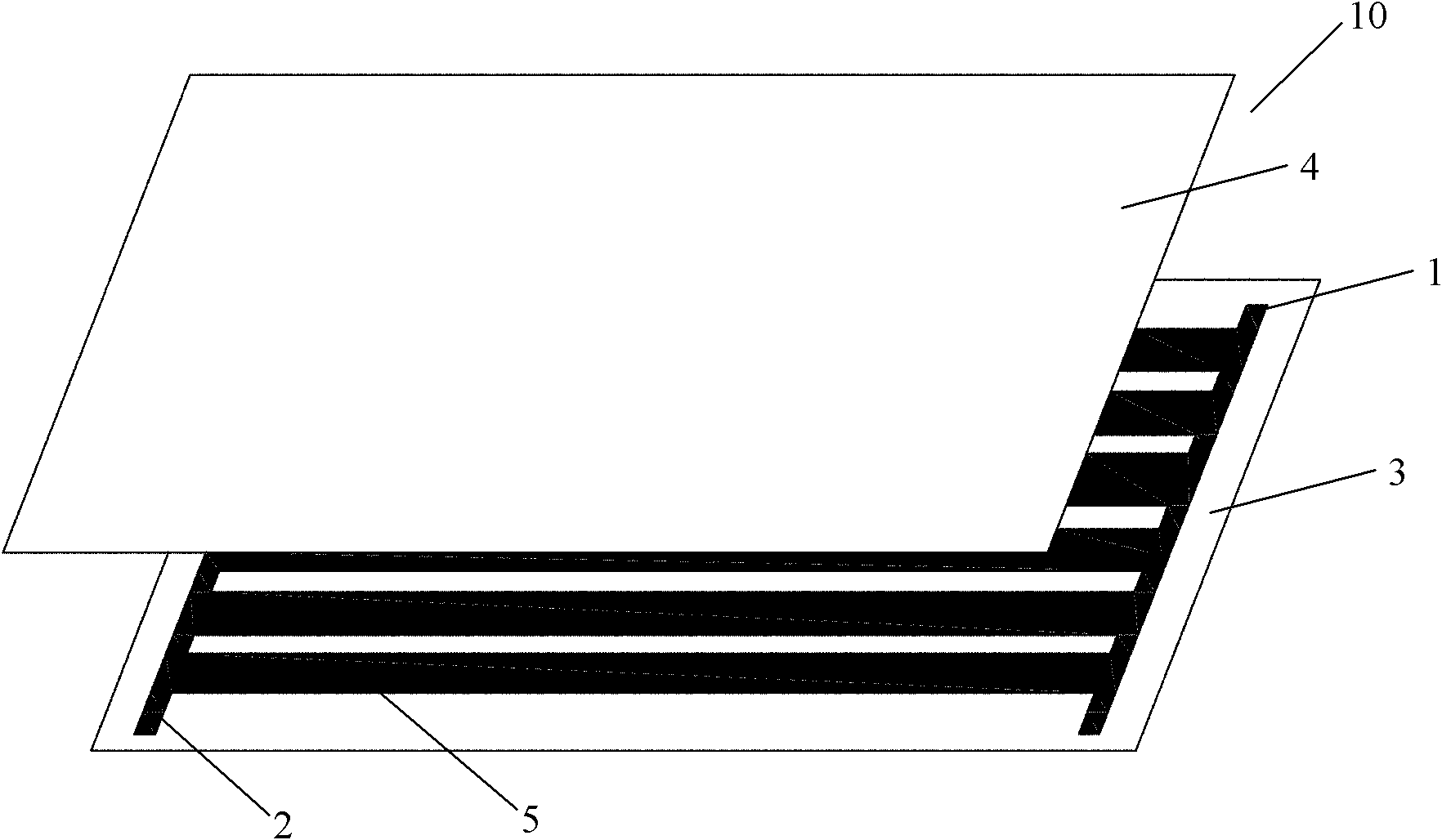

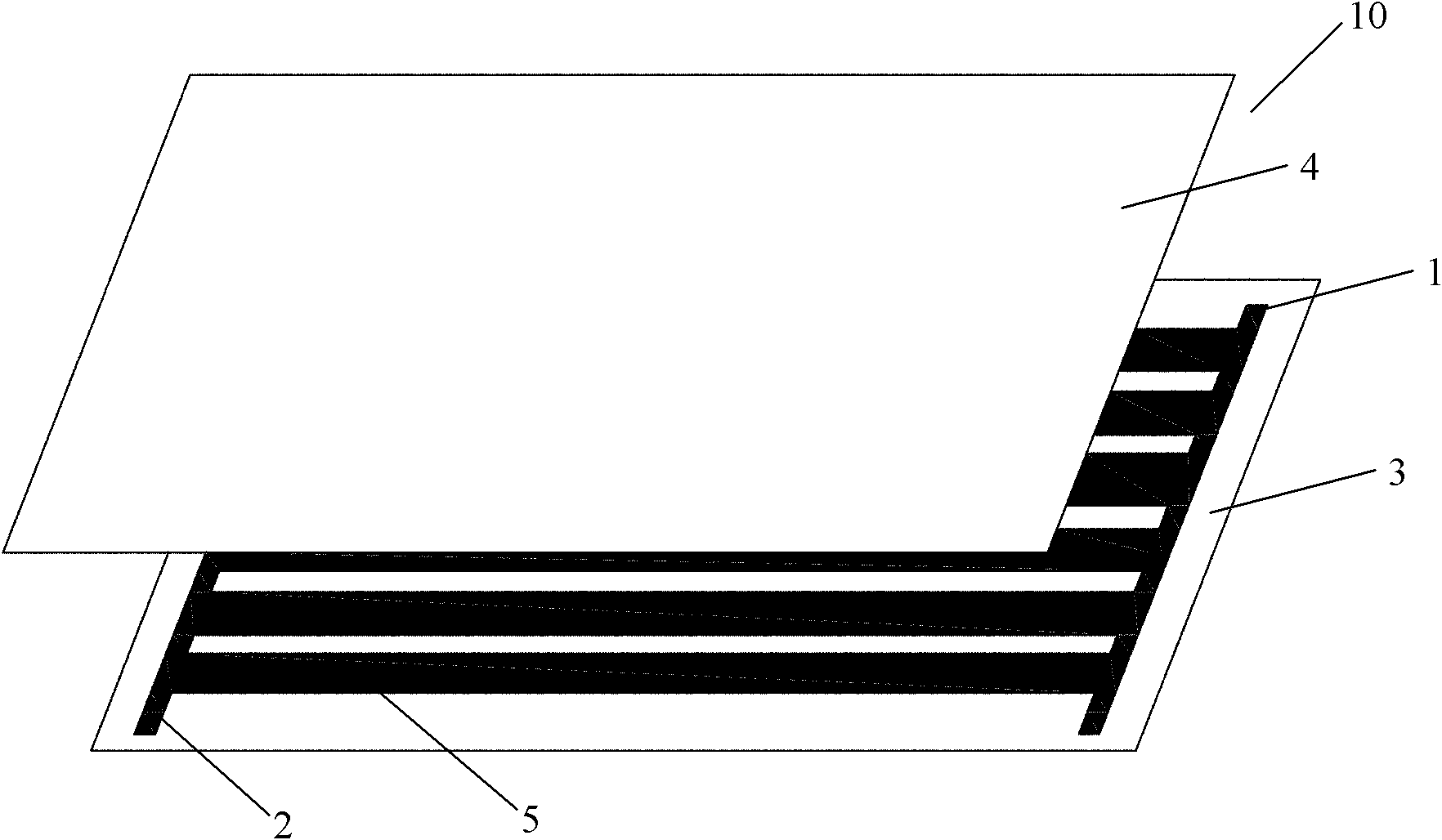

[0039] Carbon crystal plate (i.e. medium and high temperature carbon crystal electric heating plate) Preparation Example 1

[0040] a) Preparation of raw materials:

[0041] 1. The 1000~3000 mesh carbon crystal powder obtained in the preparation example 1 of the above-mentioned carbon crystal powder is 20% by weight, and the 1000~3000 mesh silicon dioxide (Si02 ) in a proportion of 80% by weight, mixed into a medium-high temperature carbon crystal electrothermal mixture;

[0042] ②Pine perfume, the dosage is 10% of the total amount of the above medium and high temperature carbon crystal electr...

preparation Embodiment 3

[0061] The carbon crystal powder obtained in the preparation example 2 of the above carbon crystal powder is 40% by weight, and 60% by weight of silicon dioxide and rosin water are added, and the consumption is 1% of the total amount of the above-mentioned medium and high temperature carbon crystal electric heating mixture. 20%. Then carbon crystal plate C was prepared according to the steps in Example 1 for the preparation of a carbon crystal plate (ie, a medium-high temperature carbon crystal electric heating plate).

[0062] For the carbon crystal plates A, B and C prepared by the above method, the heating time test, the surface temperature uniformity test and the surface insulation test were respectively carried out, and the obtained results are as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com