Method for determining stable formation domain for radial-axial ring rolling

An axial rolling and ring technology, which is applied in the field of determining the radial and axial rolling and stable forming of rings, can solve the problems of difficult to guarantee product quality, long design cycle and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

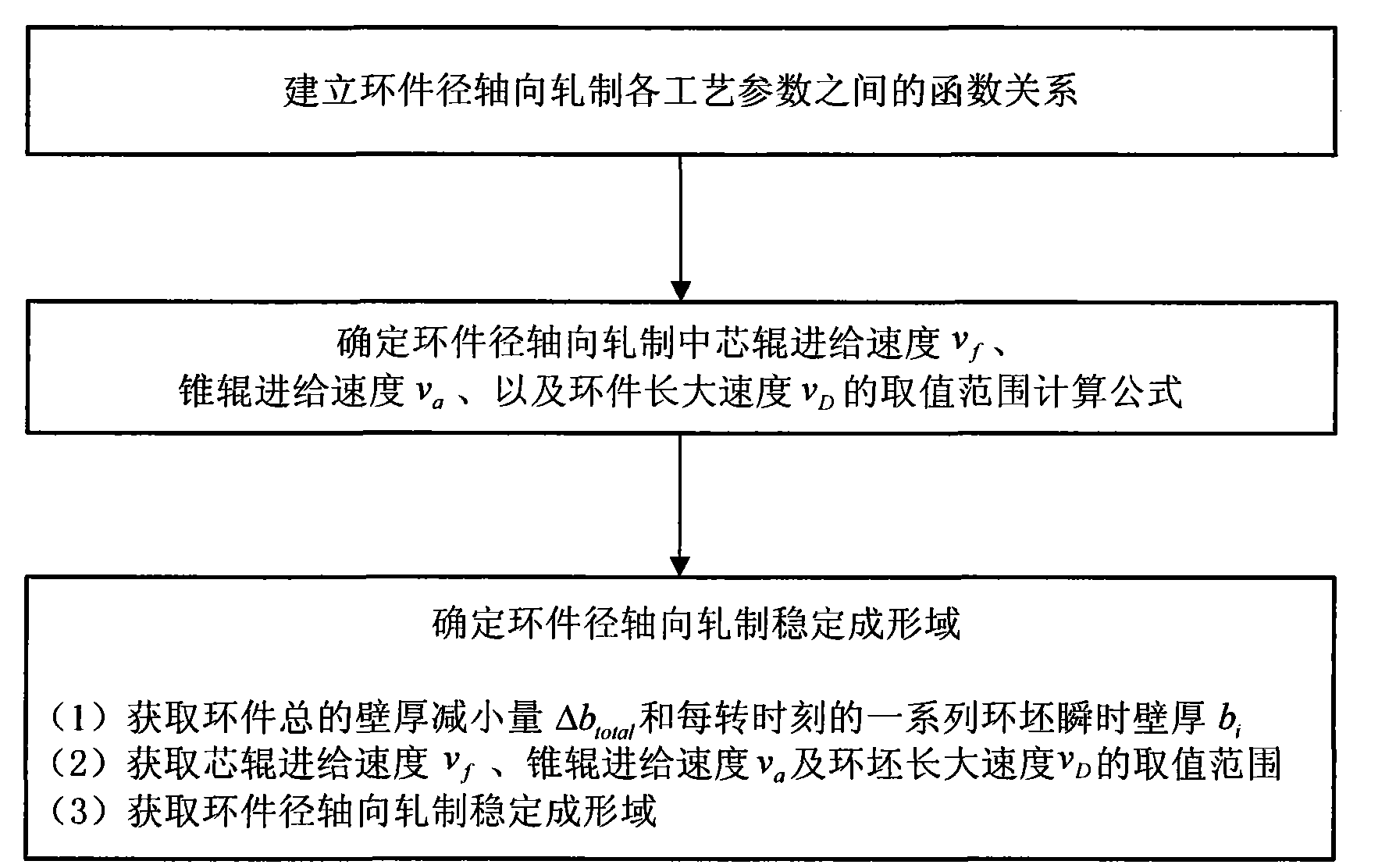

[0048] This embodiment is a method for determining the stable forming zone of ring radial and axial rolling. The goal is to control the uniform growth of the ring blank. By establishing the functional relationship between the various process parameters of the forming process, the selection of key process parameters is determined. Value range to obtain the stable forming domain of the forming process, the specific steps are as follows:

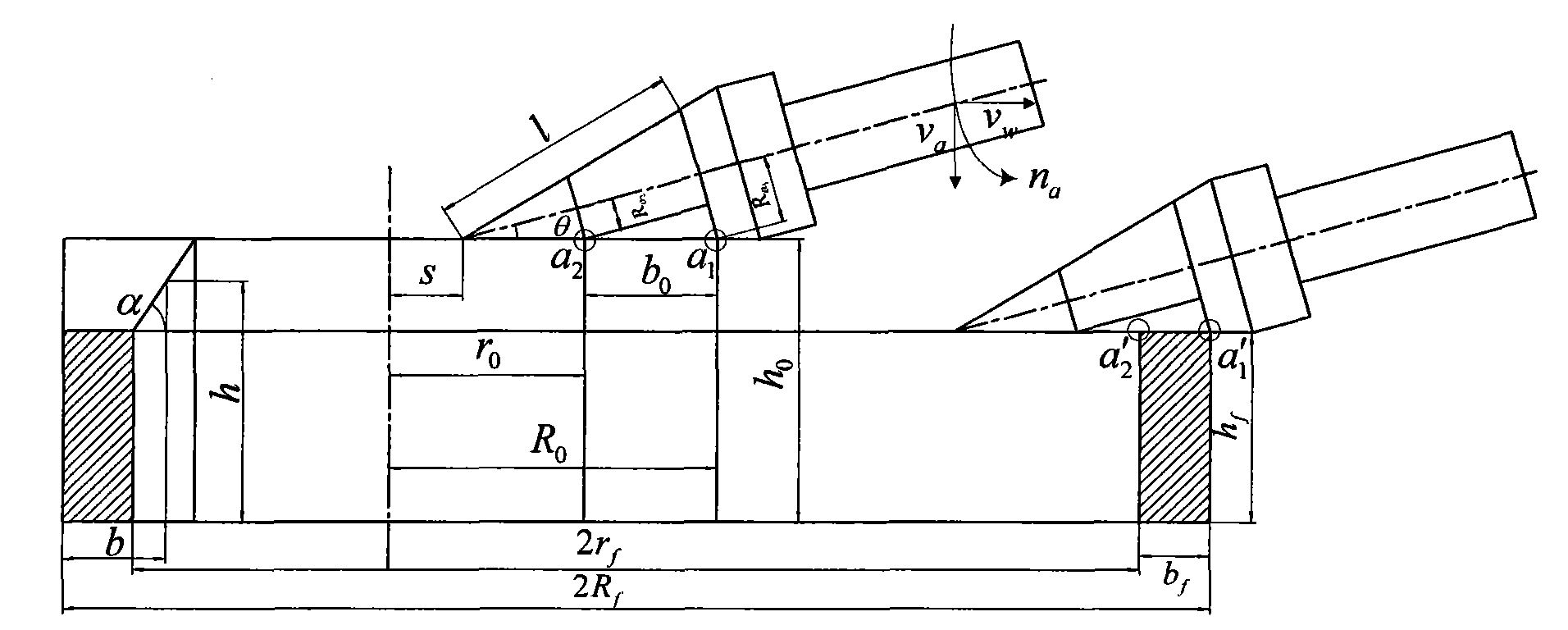

[0049] Step 1: Establish the functional relationship between the process parameters of the radial and axial rolling of the ring to ensure that the radial rolling and the axial rolling process are coordinated with each other; these process parameters include: core roll feed speed v f , Ring billet growth speed v D , Driving roller speed n 1 , Cone roller feed speed v a , Cone roller speed n a , The retreat speed of the cone roller v w ;

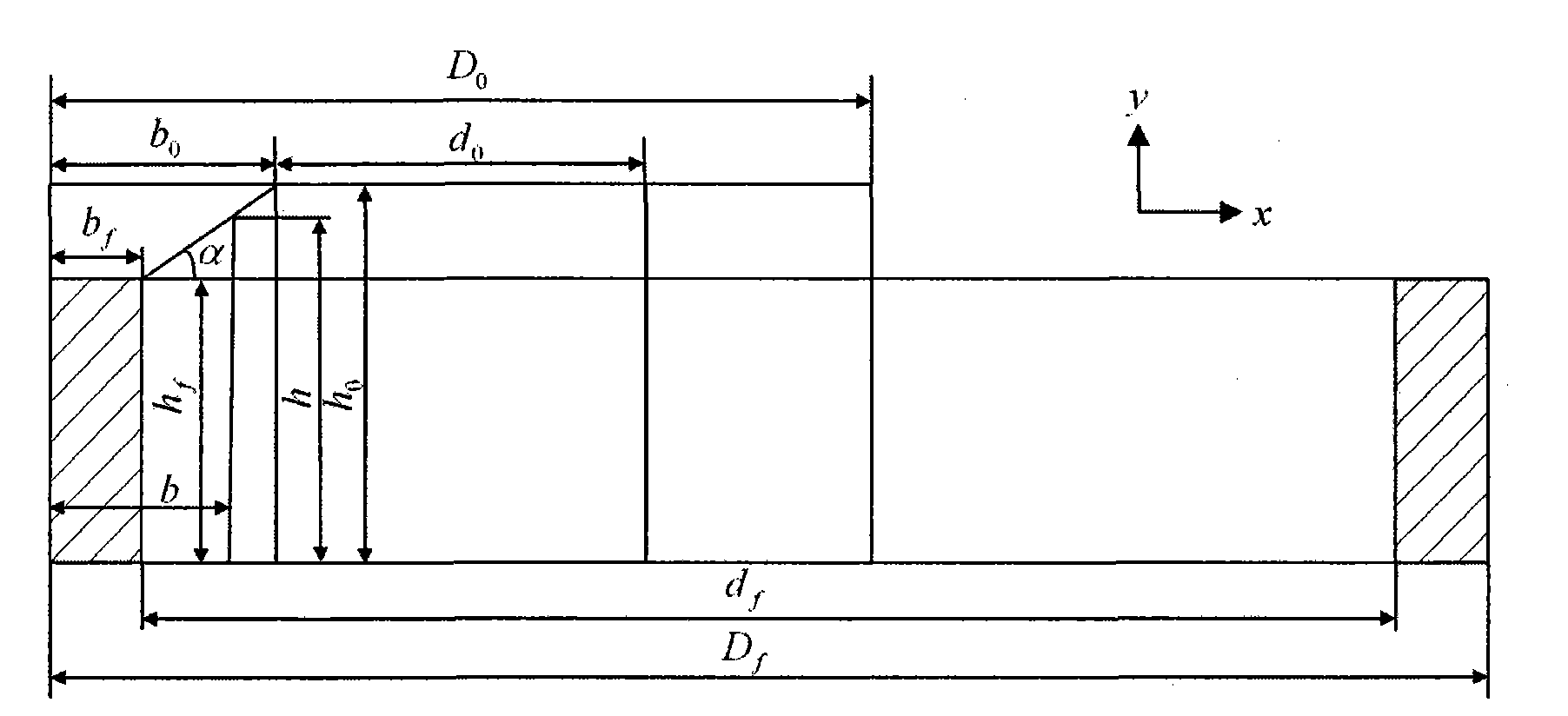

[0050] The section changes before and after the ring diameter and axial rolling are as follows figure 2 Shown. i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com