Phase change thermal storage material and manufacturing method thereof

A technology of phase change heat storage and mass percentage, applied in heat exchange materials, chemical instruments and methods, heat storage heaters, etc., can solve problems such as small heat storage per unit volume, supercooling and phase separation, and low material density , to achieve the effect of stable safety performance, stable performance and low corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] According to mass percentage, take 40 parts of silicon oxide, 9 parts of aluminum oxide, 0.06 part of iron oxide, 0.2 part of calcium oxide, 0.05 part of magnesium oxide, 3 parts of potassium oxide, 3 parts of sodium oxide and 6 parts of zinc oxide, put the above materials in a mortar 38.69 parts by mass of water were added to the mixture and mixed uniformly to obtain a phase change material. The phase change temperature of the phase change material was 120.18° C. and the heat of phase change was 1481 J / g.

Embodiment 2

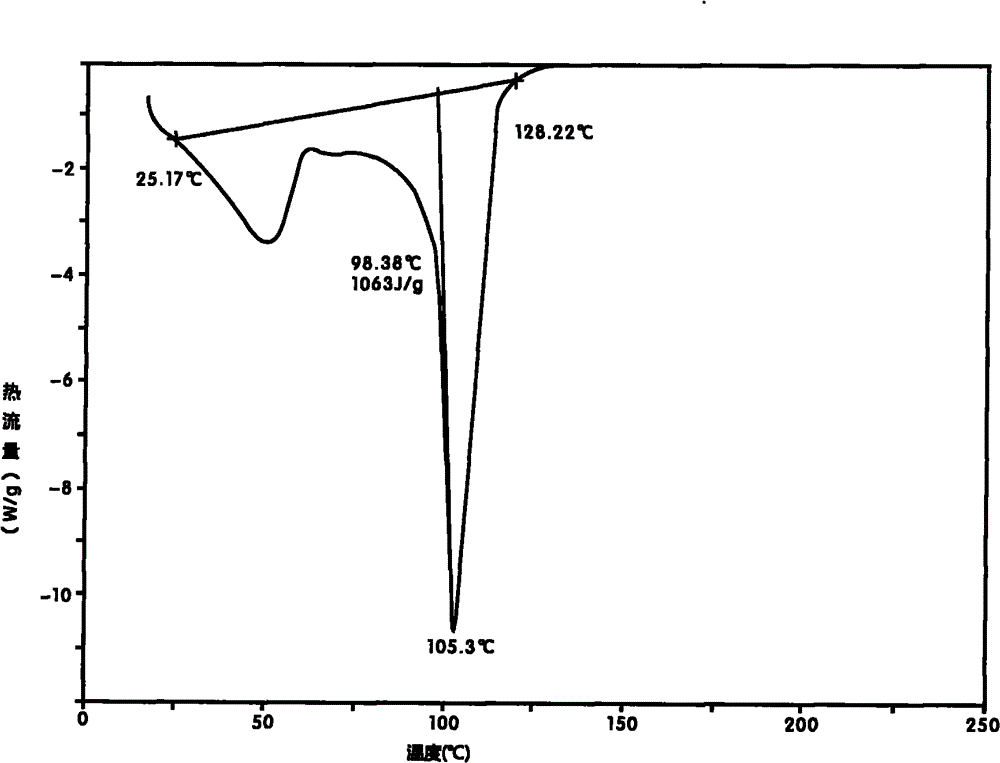

[0029] Take 45 parts of silicon oxide, 11 parts of aluminum oxide, 0.3 parts of iron oxide, 0.5 parts of calcium oxide, 0.4 parts of magnesium oxide, 4 parts of potassium oxide, 5 parts of sodium oxide and 11 parts of zinc oxide according to mass percentage, put the above materials in a mortar After fully grinding in a medium, add 22.8 parts by mass of water and mix uniformly to obtain a phase change material. The phase change temperature of the phase change material is 105.3° C., and the heat of phase change is 1237 J / g.

Embodiment 3

[0031] Take 43 parts of silicon oxide, 10 parts of aluminum oxide, 0.1 part of iron oxide, 0.3 parts of calcium oxide, 0.12 parts of magnesium oxide, 3.5 parts of potassium oxide, 4.5 parts of sodium oxide and 8 parts of zinc oxide according to mass percentage, and put the above materials in a mortar After being fully ground in a medium, 30.48 parts by mass of water was added and mixed uniformly to obtain a phase change material. The phase change temperature of the phase change material was 103.5° C., and the heat of phase change was 1311 J / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com