Method and device for medium-consistency refining and pumping

A pulp pump and thick pulp technology, applied in pulp beating/refining method, textile and papermaking, fiber raw material processing, etc., can solve the problems of unstable production system, difficult to stabilize concentration, poor fluidity, etc. The effect of reducing usage and reducing power consumption fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

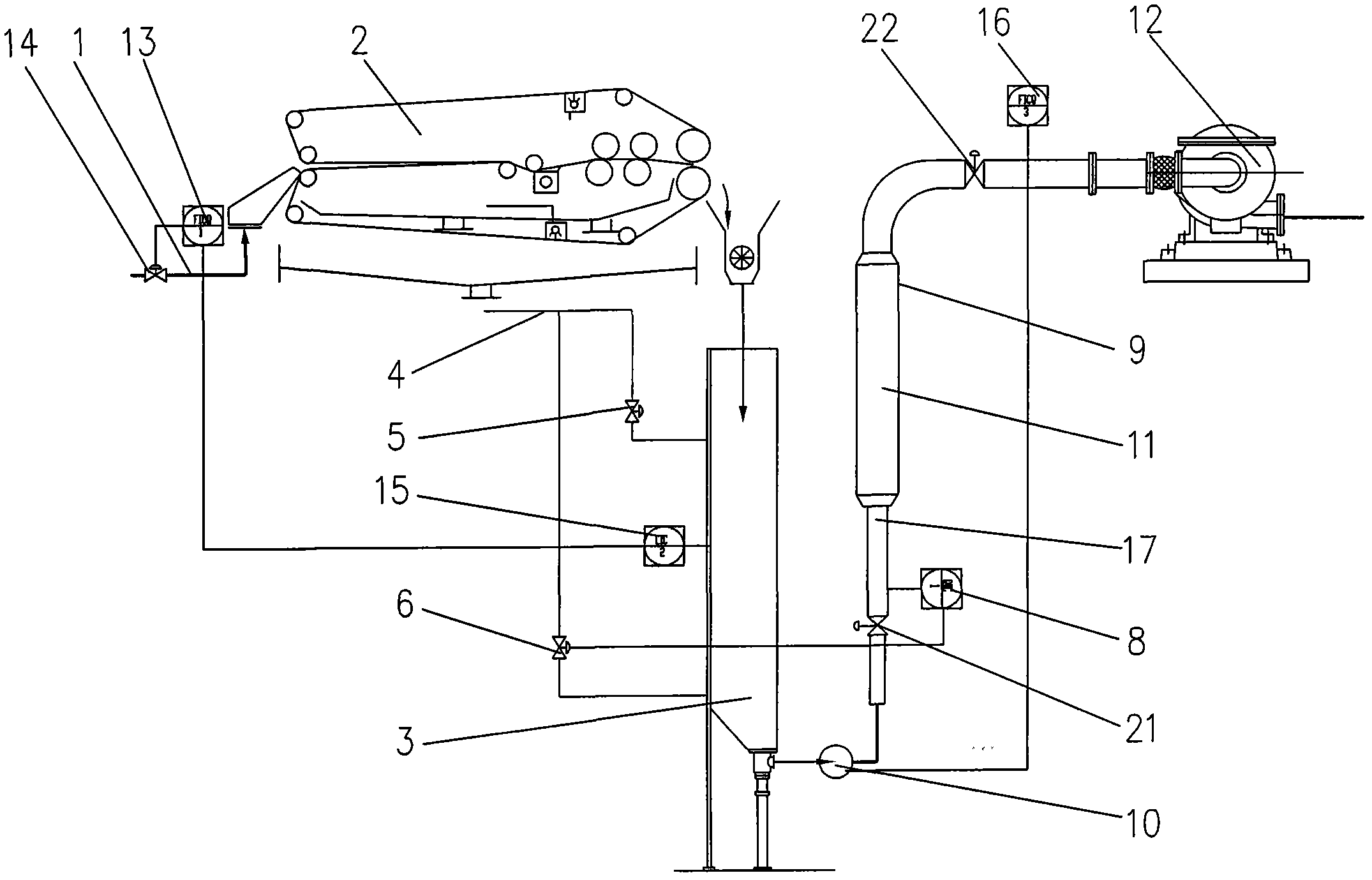

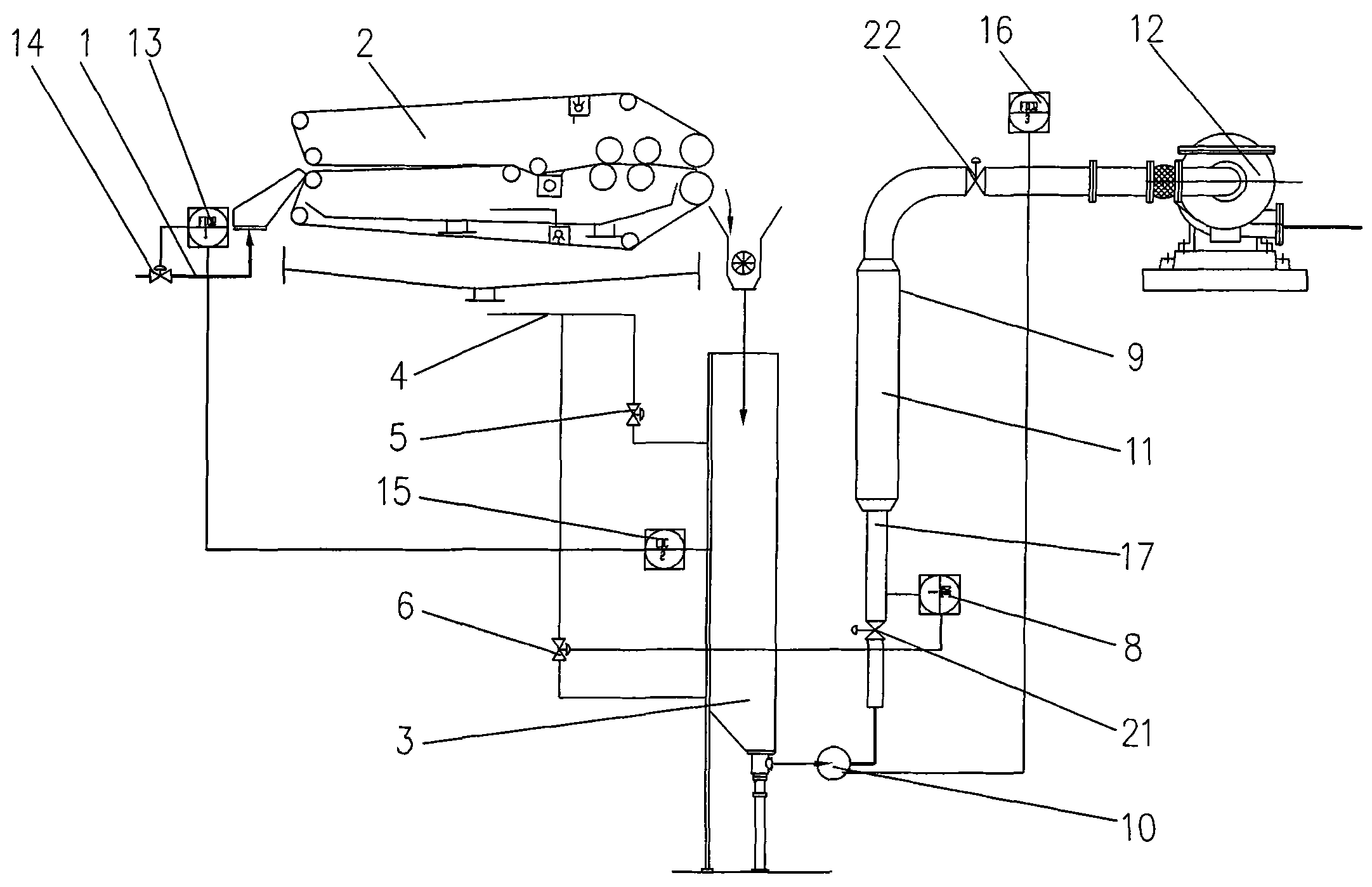

[0028] A medium-consistency beating pumping method in this embodiment includes the following steps:

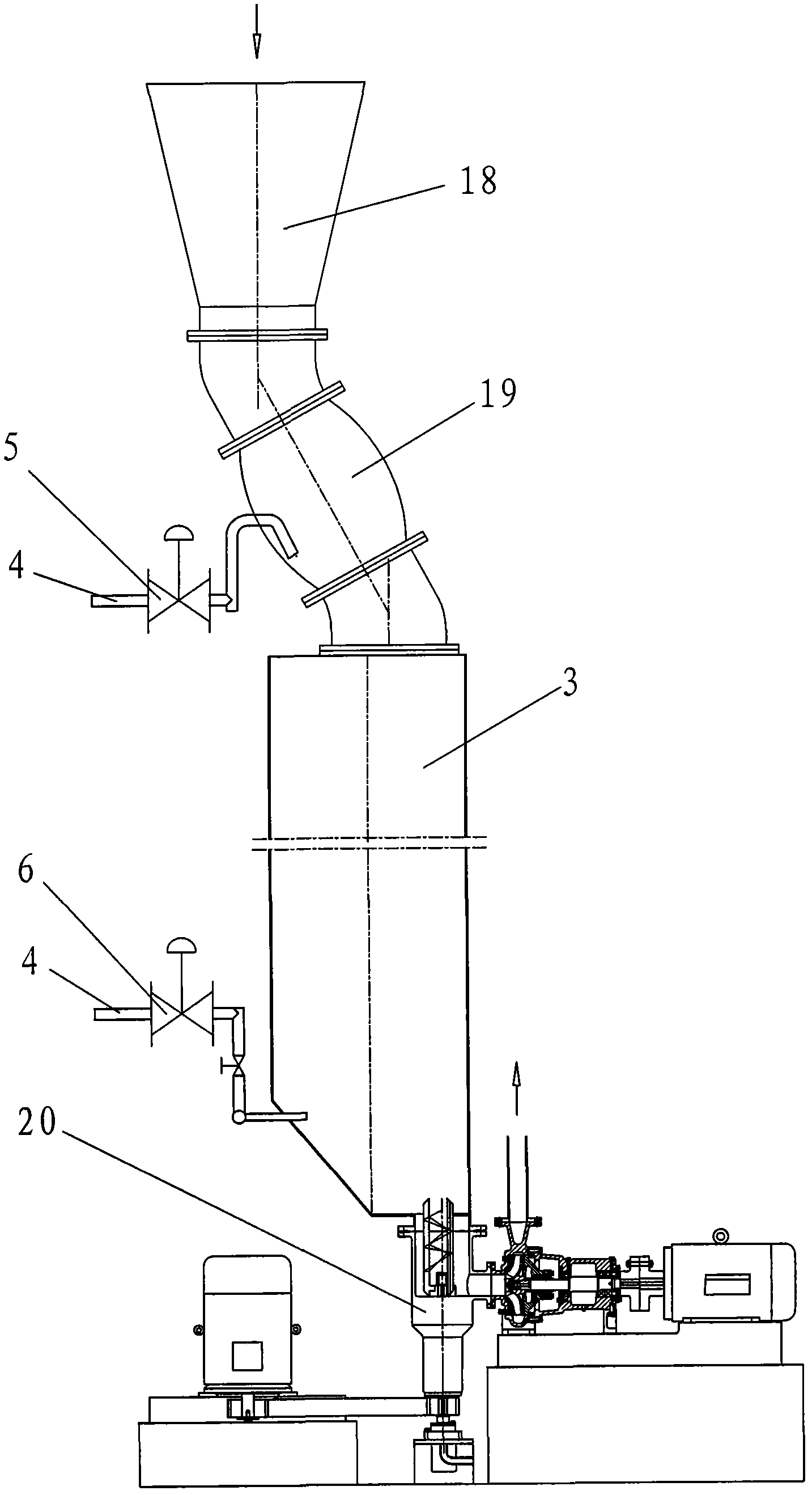

[0029] (1) The slurry is sent to the thickening equipment 2 through the low-concentration pipeline 1, and the slurry is dehydrated and concentrated until its concentration is at least 2% higher than the set value;

[0030] In this process, the low-concentration flow meter 13 detects the slurry flow in the low-concentration pipeline 1 in real time, and then controls the opening of the low-concentration valve 14 by means of PID adjustment; and the riser level gauge 15 detects the medium-concentration riser 3 in real time. Then adjust the setting value of the low-concentration flowmeter 13; when the detection value of the slurry level of the riser level gauge 15 is 30 to 70%, the setting value of the low-concentration flowmeter 13 needs to be adjusted Adjustment; specifically: when the slurry level detection value of the standpipe level gauge 15 is ≥70%, reduce the setting value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com