A preparation method and pumping process of high-strength lightweight aggregate concrete

A lightweight aggregate concrete, high-strength technology, applied in the field of lightweight aggregate concrete, can solve the problems of low activity, affect the construction of lightweight aggregate concrete, strength limitation, etc., and achieve the effects of improving pore structure, shortening construction time, and increasing early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

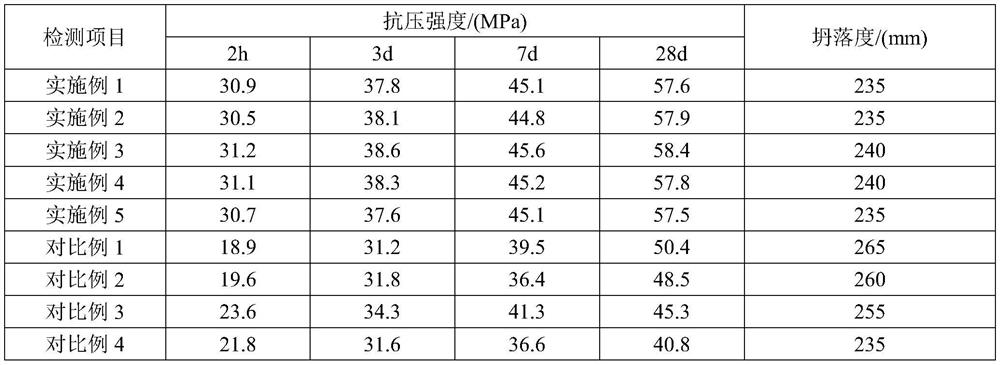

Examples

Embodiment 1

[0043] A method for preparing high-strength lightweight aggregate concrete, the ratio of raw materials is shown in Table 1.

[0044] S1. Pretreatment of fly ash

[0045] A. In the case of constant stirring, spray water into the fly ash, the water is completely absorbed by the fly ash, the amount of water added is 30% of the total weight of the fly ash, and the average particle size of the fly ash 20μm, the fly ash is Class I fly ash, and the fly ash is selected from Chengdu Junrui Building Materials Co., Ltd.;

[0046] B. Under the conditions of constant stirring and a temperature of 115°C, carry out constant temperature treatment on the fly ash in step A, most of the water in the fly ash will volatilize, and a small amount of water will remain in the fly ash, and the fly ash The water content reaches 4wt%;

[0047] C. Under nitrogen protection and a temperature of 530°C, roast the fly ash in step B. The residual water in the fly ash increases the hydroxyl content on the sur...

Embodiment 2

[0053] A method for preparing high-strength lightweight aggregate concrete, the ratio of raw materials is shown in Table 1.

[0054] S1. Pretreatment of fly ash

[0055] A. In the case of constant stirring, spray water into the fly ash, the water is completely absorbed by the fly ash, the amount of water added is 35% of the total weight of the fly ash, and the average particle size of the fly ash 25μm, the fly ash is Class I fly ash, and the fly ash is selected from Chengdu Junrui Building Materials Co., Ltd.;

[0056] B. Under the conditions of constant stirring and a temperature of 110°C, carry out constant temperature treatment on the fly ash in step A, most of the water in the fly ash will volatilize, and a small amount of water will remain in the fly ash, and the fly ash The water content reaches 5wt%;

[0057] C. Under nitrogen protection and a temperature of 550°C, roast the fly ash in step B. The residual water in the fly ash increases the hydroxyl content on the sur...

Embodiment 3

[0063] A method for preparing high-strength lightweight aggregate concrete, the ratio of raw materials is shown in Table 1.

[0064] S1. Pretreatment of fly ash

[0065] A. In the case of constant stirring, spray water into the fly ash, the water is completely absorbed by the fly ash, the amount of water added is 35% of the total weight of the fly ash, and the average particle size of the fly ash 23μm, the fly ash is Class I fly ash, and the fly ash is selected from Chengdu Junrui Building Materials Co., Ltd.;

[0066] B. Under the conditions of constant stirring and a temperature of 115°C, carry out constant temperature treatment on the fly ash in step A, most of the water in the fly ash will volatilize, and a small amount of water will remain in the fly ash, and the fly ash The water content reaches 4wt%;

[0067] C. Under nitrogen protection and a temperature of 530°C, roast the fly ash in step B. The residual water in the fly ash increases the hydroxyl content on the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com