Method for determining coal mass gas content by advancing face gas emission parametric inversion

A technology of gas emission amount and gas emission, which is applied in the field of coal gas content measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Preferred embodiments of the present invention will be described in detail below.

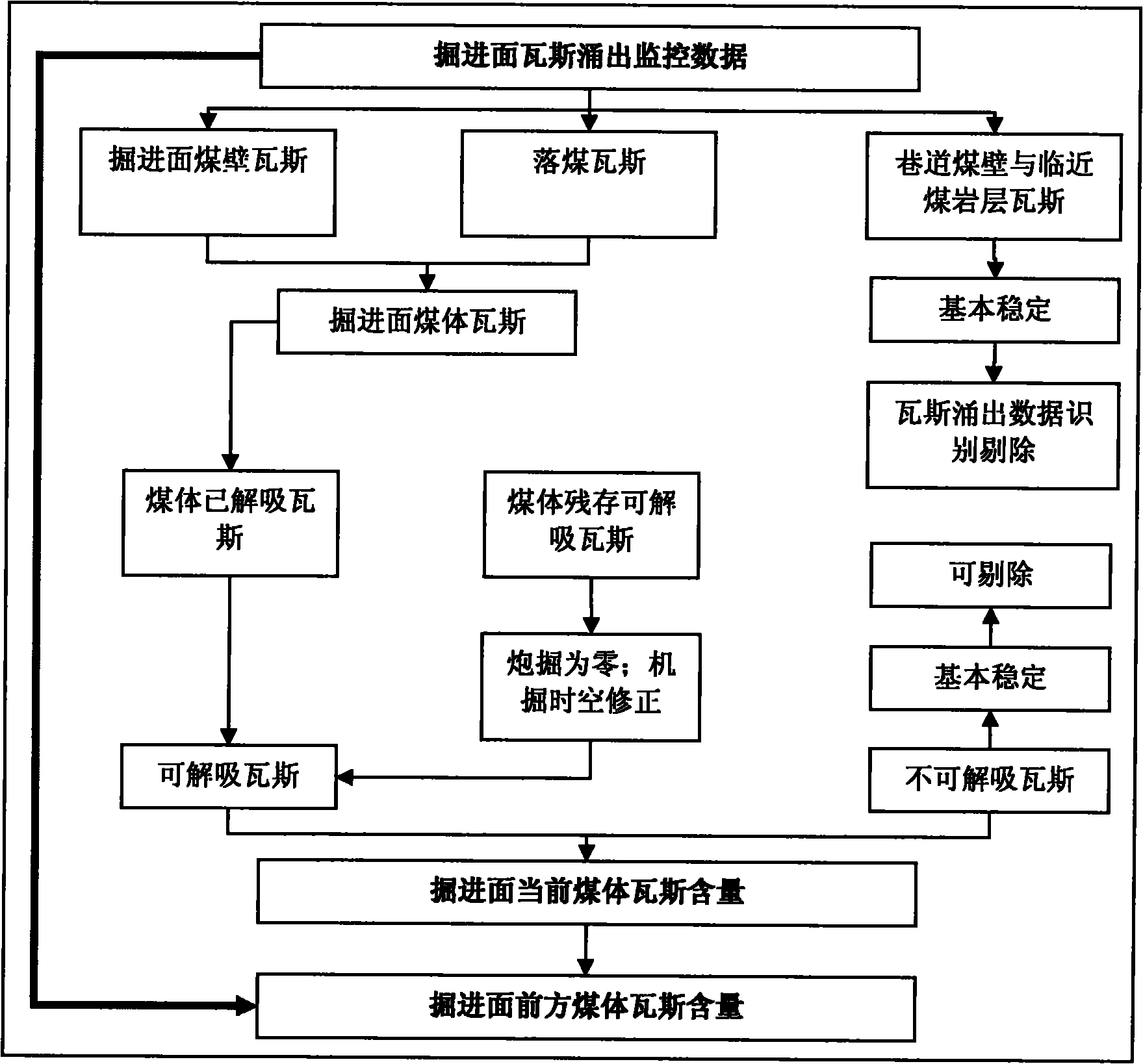

[0058] see figure 1 , The gas gushing out of the tunneling face can be divided into three types: the gas gushing out of the coal wall of the tunneling face, the gas gushing out of the coal walls of the two sides of the roadway or adjacent coal and rock formations, and the gas gushing out of the falling coal. The coal gas in the excavation face mainly includes non-desorbable gas and desorbable gas. The non-desorbable gas is basically stable, and the desorbable gas is further divided into residual gas from falling coal and desorbed gas.

[0059] At the underground production site, we believe that the residual gas in coal falling is basically stable or does not change much. During blasting, it is considered to be constant or basically zero. In machine digging, the residual gas in coal falling is considered to be affected by the gas content before coal mining. Influenced by the tunneling s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com