Speed ratio control device with belt type continuously variable transmission

A technology of continuously variable transmission and control device, which is applied in the direction of transmission, components with teeth, transmission control, etc., can solve the problem of high machining accuracy requirements of hydraulic actuators, uncontrollable speed ratio adjustment accuracy, and hydraulic actuator efficiency. Low problems, to achieve the effect of continuous stepless change, convenient control and high speed ratio adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

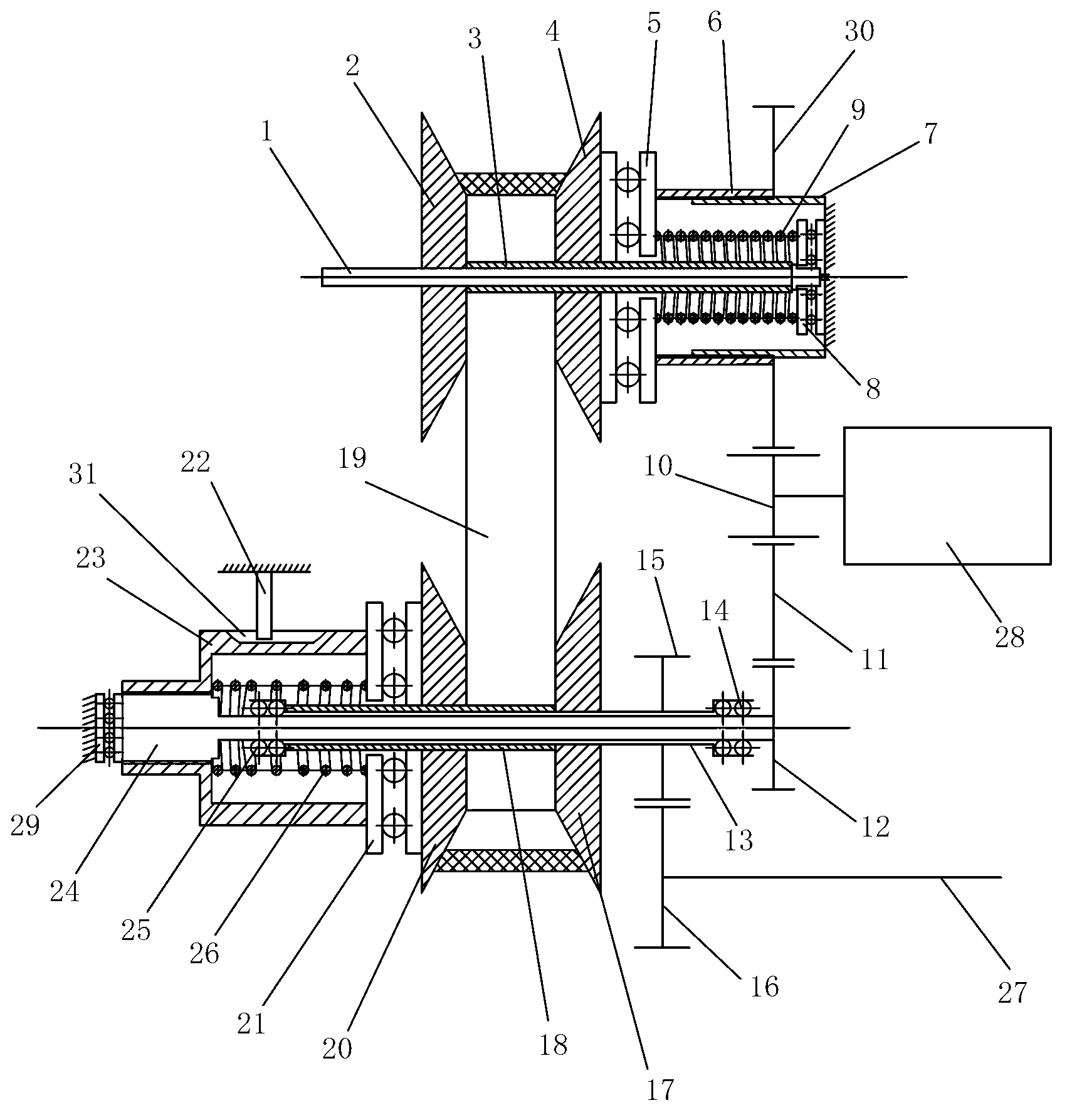

[0010] See figure 1 The speed ratio control device of the belt type continuously variable transmission of the present embodiment includes: a DC motor, a controller for controlling the steering and rotation angle of the output shaft of the DC motor, and a power input shaft 1 connected to the output shaft of the engine when in use. , the driving pulley that is located on the power input shaft 1, the power output shaft 13 that is connected with the vehicle transmission shaft 27 during use, the driven pulley that is located on the power output shaft 13, connects the driving pulley and The V-shaped transmission belt 19 of the driven pulley.

[0011] The driving pulley includes: a driving pulley fixed plate 2 fixed on the power input shaft 1, a driving sleeve 3 arranged on the right side of the driving pulley fixed plate 2 and vacantly sleeved on the power input shaft 1 , the driving pulley moving disc 4 that is empty on the driving shaft sleeve 3, the first device that is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com