Ceramic plate detection equipment and detection method

A technology for testing equipment and ceramic plates, which is applied in the direction of measuring devices, instruments, and material analysis through optical means. It can solve the problems of straight laser lines, missing edges, missing corners, and drum edges, etc., to achieve efficient and accurate detection. , The effect of simple detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

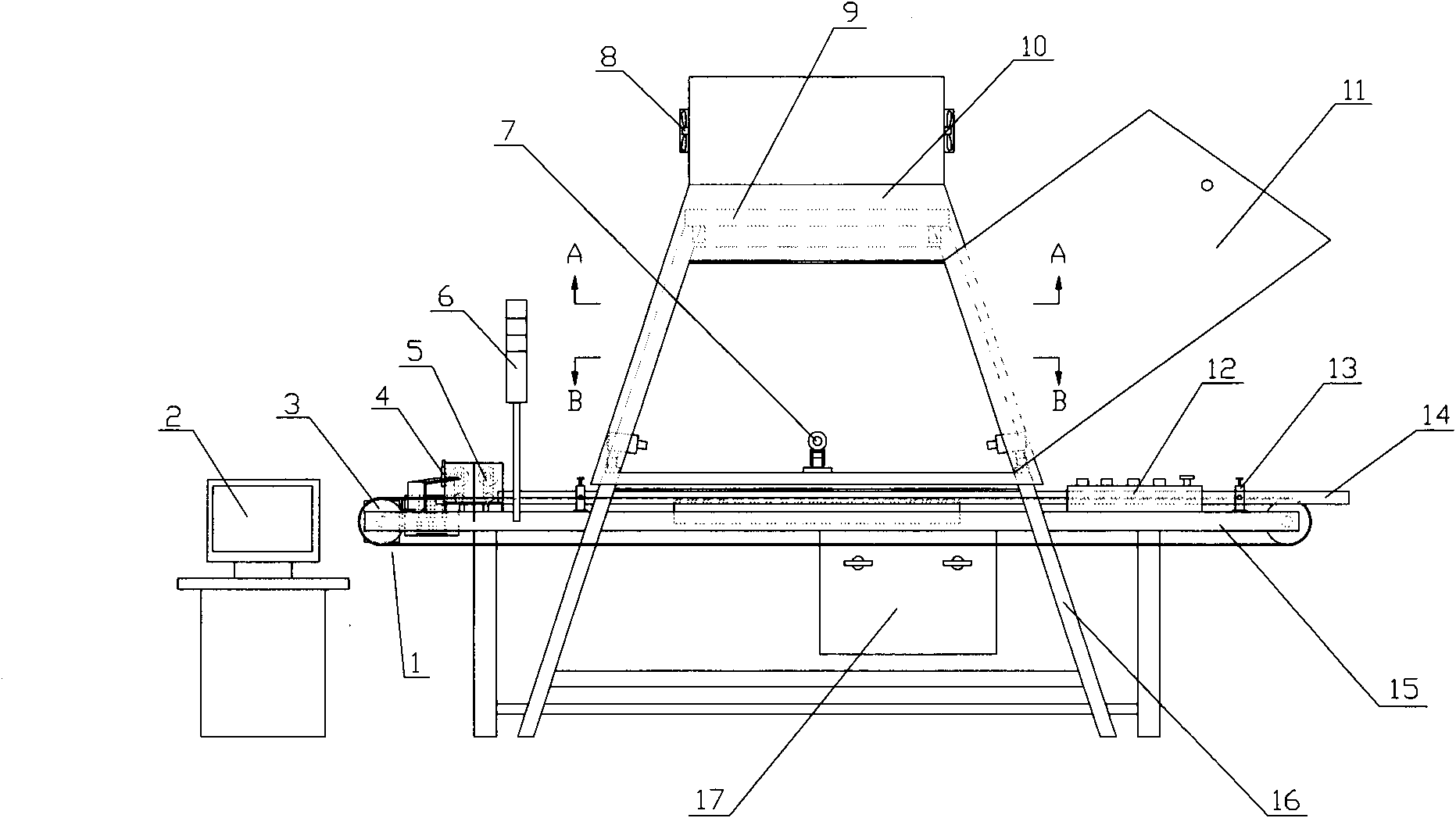

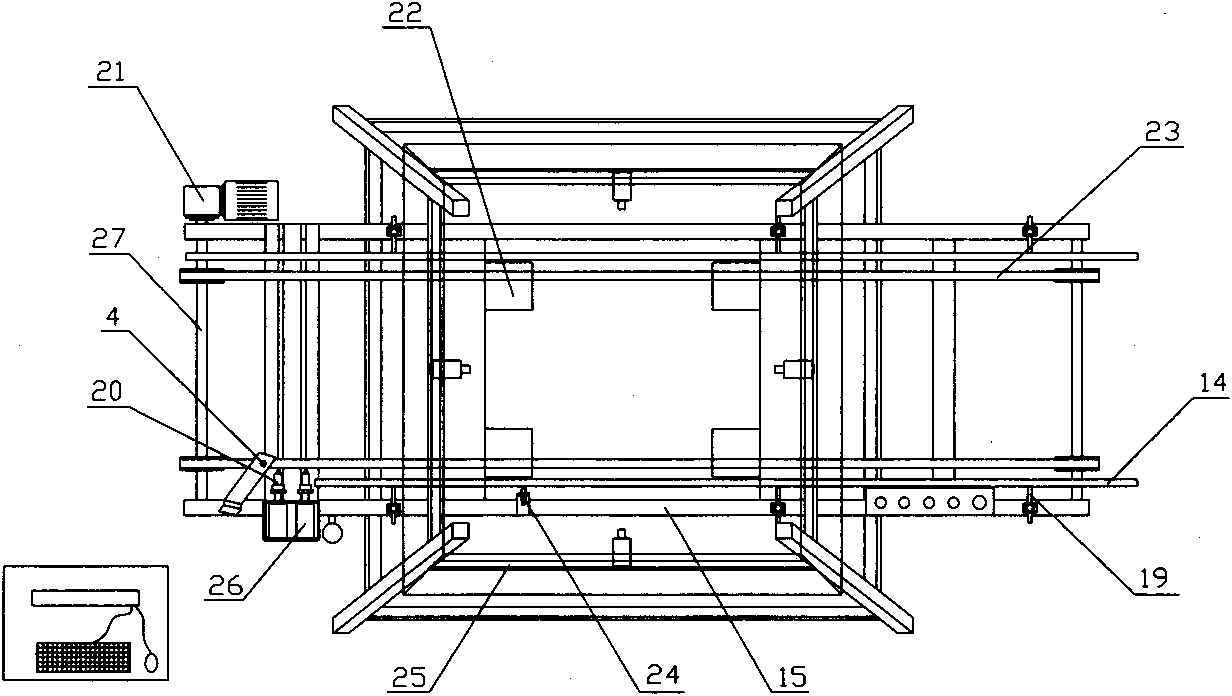

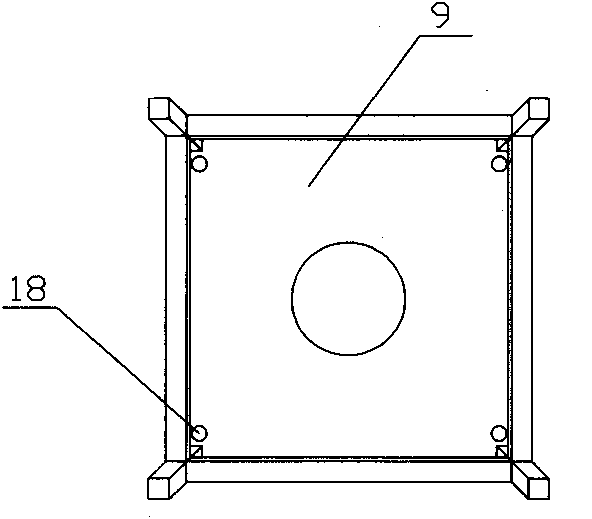

[0011] Embodiment 1: with reference to attached Figure 1~3 . A kind of ceramic plate detection equipment, it comprises conveying mechanism 1 and support 16, described is provided with conveying mechanism 1 and is positioned at support 16, is positioned at the four sides of support 16 above conveying mechanism 1 and is respectively provided with linear laser emitter 7 and angle is adjustable, The linear laser line shot obliquely from top to bottom by the linear laser emitter 7 forms a rectangular linear laser frame on the conveying surface of the conveying mechanism; The signal output end of the high-resolution industrial camera 18 is connected with the computer 2 signal input end.

[0012] The support 16 is a trapezoid with a small upper part and a larger lower part, and the area formed by the intersection of the interior of the support 16 with the conveying mechanism 1 is the detection area. Four crossbars 25 are arranged at the detection position of the trapezoid, and the...

Embodiment 2

[0019] Embodiment 2: On the basis of embodiment 1, a kind of ceramic plate detection method, (1) the optical detection probe 24 that is positioned at one side of assembly line, after detecting the arrival of ceramic plate, stop conveying by controller instruction conveying mechanism, four The area occupied by the backlight board 22 is greater than the area of the detected ceramic board, so the light projected by the four backlight boards 22 positioned directly below the ceramic board irradiates the edge of the ceramic board to show the outline of the ceramic board. Four ultra-high-resolution industrial cameras 18 immediately take pictures of the ceramic plate against the flicker-free plane backlight and input it into the computer to save the picture. After the computer software rapid graphic image analysis and calculation processing, the length of the four sides of the ceramic plate and its composition are obtained. (2) the linear laser lines emitted by the four linear laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com