Optical detection method for parallelism of planar array CCD target surface and installation locating surface

An optical detection, installation and positioning technology, applied in the direction of using optical devices, measuring devices, mechanical gap measurement, etc., can solve the problems of difficult optical system focal depth requirements, poor parallelism of CCD target surface, affecting the quality of CCD imaging, etc. Improved image quality, easy operation, and the effect of reliable measurement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

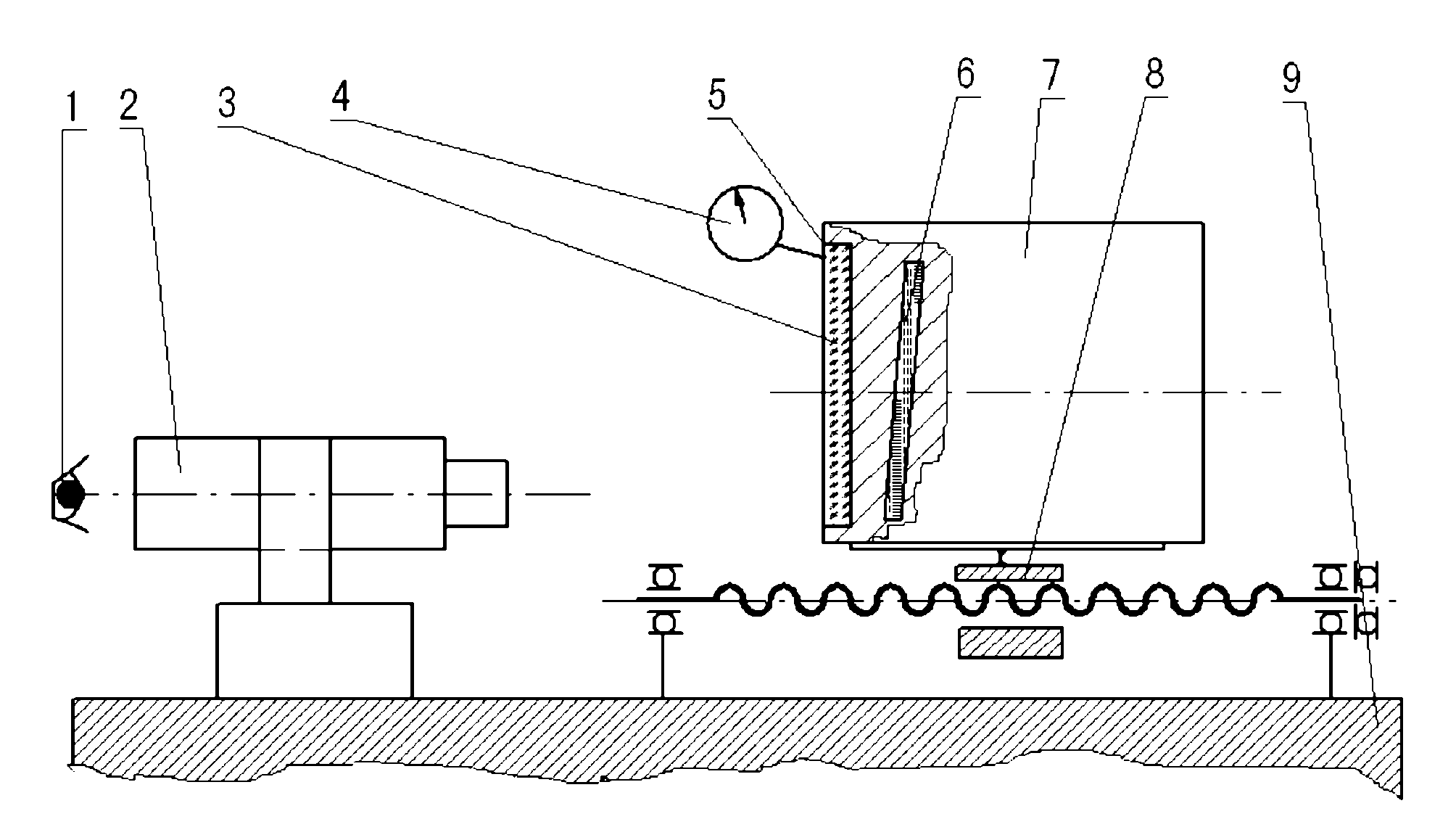

[0016] Specific implementation mode 1. Combination figure 1 and figure 2 Illustrate this embodiment, a kind of optical detection method of the parallelism between the target surface 6 of the area array CCD and the installation positioning surface, the method is completed by the following steps:

[0017] Step 1, using a high-precision linear displacement platform 8 to move the CCD target surface 6 and the mechanical installation surface 5 to the focal plane of the tool microscope 2 respectively;

[0018] Step 2, using the dial indicator 4 to measure the moving distance of the high-precision linear displacement platform 8, and using the moving distance of the high-precision linear displacement platform 8 as the distance between the CCD target surface 6 and the mechanical installation surface 5;

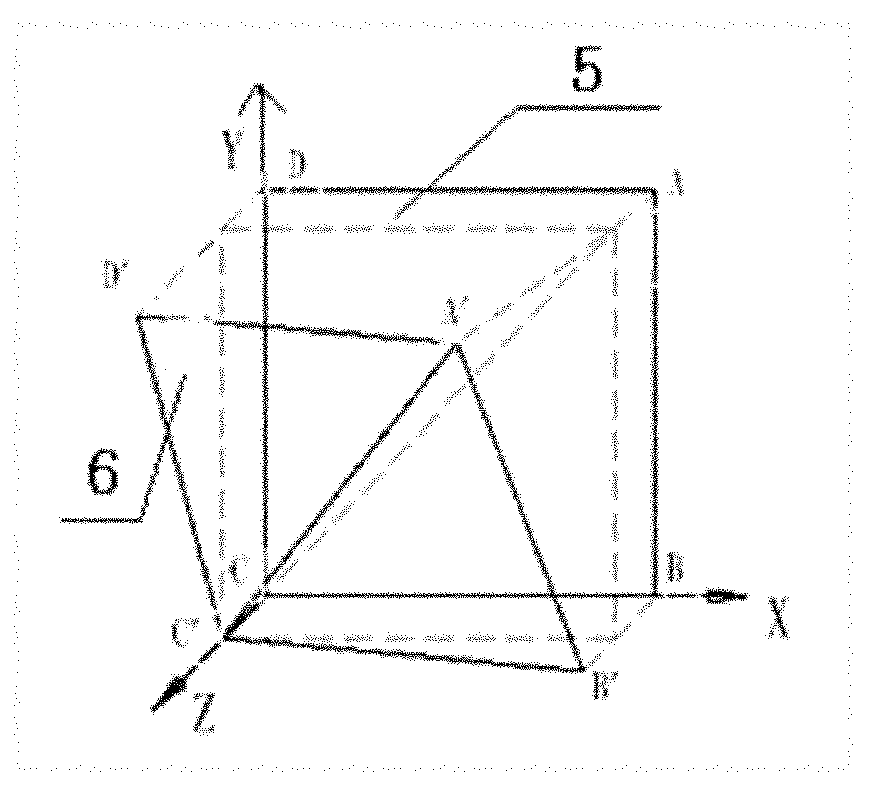

[0019] Step 3: Use any right-angled vertex of the CCD target surface 6 as the origin of the Cartesian coordinate system, and the corresponding two right-angled sides as the X-axis and...

specific Embodiment approach 2

[0022] Specific embodiment two, combine figure 2 Describe this embodiment, this embodiment is the specific example of the optical detection method of the parallelism of a kind of area array CCD target surface 6 described in the specific embodiment 1 and the installation positioning surface:

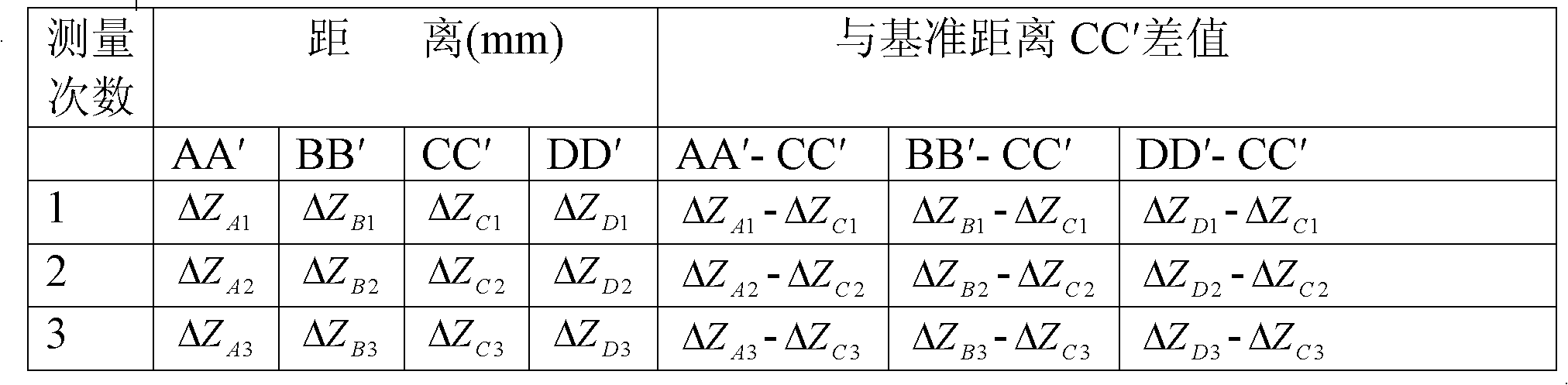

[0023] The measuring tool of the present embodiment is: tool microscope 2, dial indicator 4, high-precision linear displacement platform 8; the displacement resolution of the high-precision linear displacement platform 8 is 0.005; the measuring tool is placed on the marble platform 9, A CCD protective glass 3 is arranged in front of the rectangular area array CCD target surface 6, and a non-contact optical measurement method is adopted to observe the value read by the tool microscope 2 through the human eye 1 and calculate the distance between the CCD target surface 6 and the mechanical installation surface 5 on the X axis, The angle between the Y axis and the diagonal direction, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com